We Change the Way of Development

As an automation and simulation expert, eCon Engineering is capable of offering a one-stop-shop for the product development process.

eCon Engineering has grown continuously since its establishment in 2002. With more than 70 engineers, it is currently the largest independent engineering office in Hungary.

Our customers are very diverse, ranging from educational institutions and R&D centres to prestigious multinationals and start-ups. eCon Engineering takes a lead role in the field of co-operative research, development and innovation.

eCon has specialised knowledge of composites and their simulations. In 2019 eCon won the JEC Innovation Award in Paris in the category ‘automotive process’. eCon has ISO 9001, 27001 and Tisax level 3 certificates.

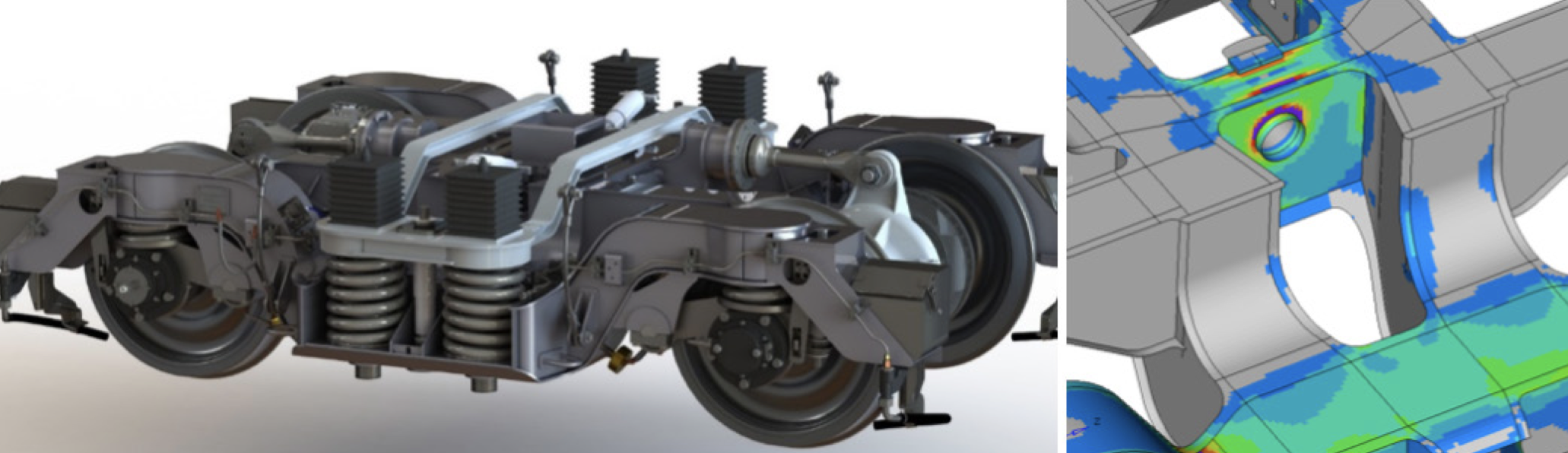

With its wide-ranging and innovative expertise, it serves domestic and international clients at the highest level. The company provides solutions to a variety of problems in the automotive, aerospace, energy, heavy truck, bus, composite and rail industries.

What eCon Engineering Offers the Railway Industry

Engineering Simulation Solutions

- Go to market faster with your product

- Have the best physical prototype in the least amount of time

- Have less scrap during manufacturing

- Enhance your product quality

- Have fewer warranty problems thanks to our optimal design and high-quality products

- Opportunity to test countless virtual prototypes instead of physical ones

- Have less waste and a smaller ecological footprint

- See and test product features and behaviours as early as the design phase

- Implement your product idea in the most cost-effective way

- No limits for innovative ideas; jump ahead of your competition

Industrial Automation Solutions

- Assembly technologies

- Robot cells

- Screwdriving stations

- Test equipment

- Technology development

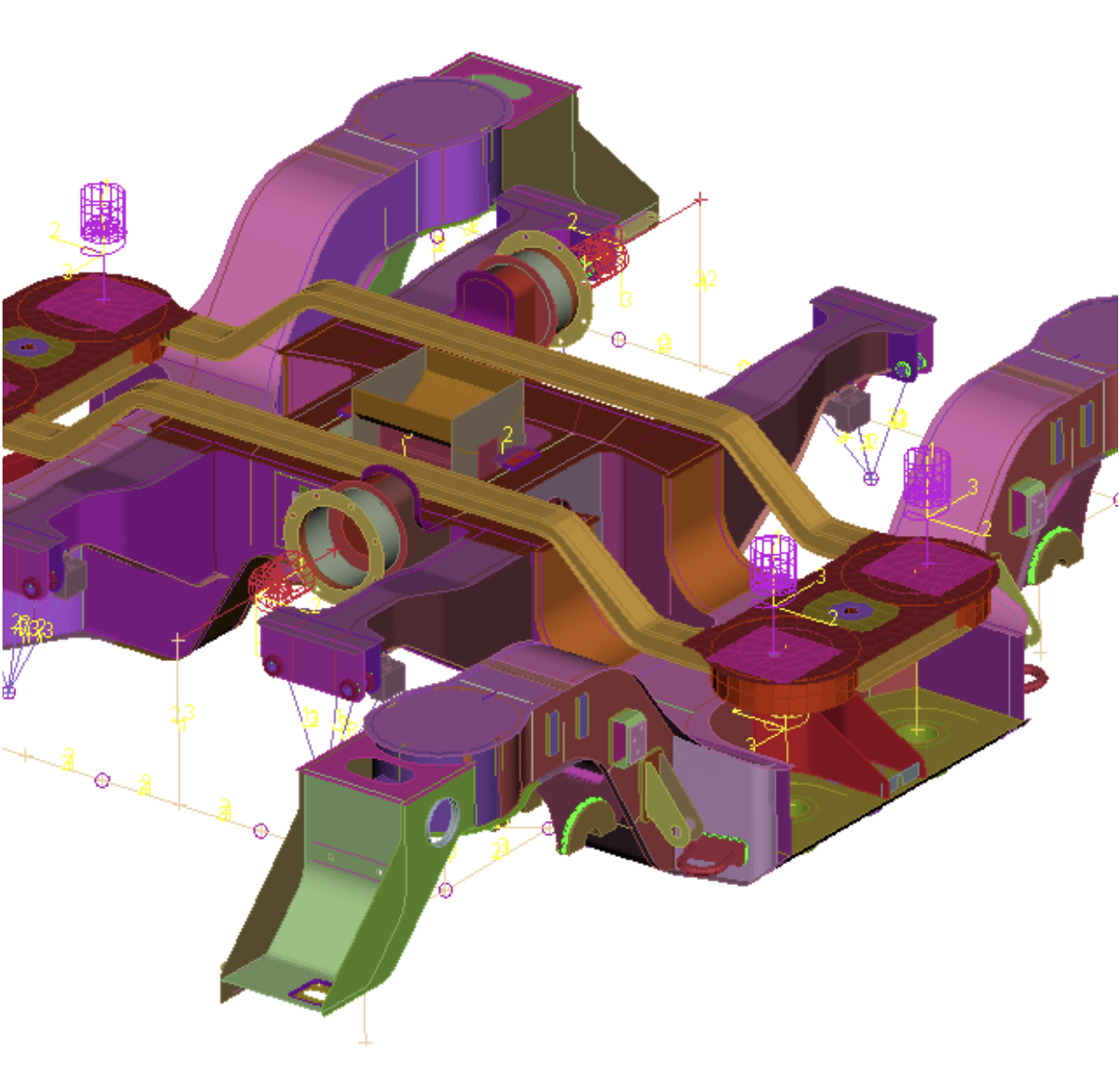

eCon Engineering provides tailor-made CAE (computer-aided engineering) and industrial automation solutions. The CAE service line offers customised solutions ranging from network and model building through collaboration with in-house CAE teams from various companies to full simulation of development processes, such as finite element analysis (FEA/FEM), computational fluid dynamics (CFD), multi-body simulations (MBS), boundary element method (BEM), 1D analysis, modelling and injection-moulding simulations. As a flexible engineering office eCon uses a wide range of CAE software, including market-leading Ansys, Moldex3D and Cast-Designer.

Our automation service line is able to cover a wide spectrum of assembly technologies while constantly being open for new technological innovations. According to the required assembly steps, we determine the best solution and integrate it into your line – regardless if it’s a fully robotic or a manual workstation. The system can be a speed-optimised machine with indexing table, a highly flexible conveyor system or a totally customised unit depending on the customers’ priorities. Our design specialist experience will be applied to your assembly machines increasing the machine up-time and reliability.

Through our sister company, eCon Trading, we also provide a wide range of robotisation solutions.

To know more about us and our wide range of case studies & customers like Bosch, Harman International, Thyssenkrupp, GE, Continental, Knorr-Bremse, the Schaeffler Group and many more, please visit us at www.econengineering.com or write to us at [email protected]