Who We Are

Blend Plants, an Italian company specialised in mobile concrete plants production, was founded in 1992 through the merger of two families, Tetoldini and Biglieri.

However, the Blend experience in the production and marketing of concrete began in 1983 with the importation of the first American plants to Italy. These were then improved.

In 2011 Blend Plants celebrated a milestone by going international: we opened a branch in Argentina.

Today, Blend Plants, which is headquartered in Rodengo Saiano (BS), Italy, can look back on 35 years of experience and boast an annual production of more than 100 plants. A total of 1,500 plants have been produced and sold worldwide to date.

Blend Automated Mobile Plants for Concrete Production

Blend has always produced automated mobile plants for the production of concrete: automation in the production process is fundamental and innovation is a key feature of business. Our solutions are the result of many years of experience, combined with attention to construction aspects in order to understand clients’ needs and deliver the innovation they require.

The goal of the company is to offer tools to improve the quality, efficiency and profitability of our customers’ work.

Blend Plants’ design skills enable us to adapt machinery to any client request thanks to a modular, flexible and structurally efficient concept.

Blend plants produce concrete, cold asphalt, coloured concrete, fibre-reinforced concrete, cementitious mixtures, soil stabilisation, mortar and screed. They are:

- E-series: E015, E025, E050 and Seventy

- A240: High Output

- C019: Live Bottom Material Handler

- MX Concrete Agitator

- Easyfloor: Mobile Paving System

Blend: A Complete Batching Plant

Blend is a complete batching plant for mixing directly on-site. Materials are stocked in separate compartments, from one to three aggregate hoppers, and dosed according to the chosen recipe. In this way there is no waste of material and only the necessary amount is mixed, in small or large quantities. By changing the recipe it is possible to mix different qualities of concrete with the same load.

Each machine can have either a diesel or an electric engine on board, or be directly connected to the truck PTO.

The intelligent on-board computer controls cement and aggregate weighing, water and the admixtures dosage: the result is certifiable concrete.

Finally, using the remote control, it is possible to keep the production and the concrete flow under constant control. The work can be managed by a single operator. No manual operations are necessary.

The combination of plants assembled on different vehicles together with horizontal cement silos, also designed by Blend, further increases working efficiency, speeds up operations and improves autonomy.

All the machines are designed in order to operate in stationary mode, on trucks or railway wagons.

Blend Mobile Concrete Mixing Plants for Railway Applications

Blend railway solutions offer a range of mobile concrete mixing plants: from the most popular Seventy model to smaller models like the E050 and the E025, and from this year, the new E015, which can be mounted on a 4×4 rail-road vehicle.

Blend Plants Wins First Railway Customer in 1997

The first railway plant was sold in Italy in 1997 to ICEFEDUE. This order was just the beginning of a series of products and improvements for the railway sector.

Blend Plant’s involvement in railway market started in Italy and rapidly extended worldwide, introducing Blend machines all over Europe and in the USA.

Blend Plants Hired by London Underground

In 2015 Blend Plants took part in an important project to create a plant for London Underground’s requirements.

The Blend mobile mixing plant for concrete production was chosen because of its innovative technological versatility: a special automated plant 17m long, weighing 11t and exhibiting a carrying capacity of 15 cubic metres.

The project planning was followed with patience and passion and Blend succeeded in creating a plant capable of satisfying all of the customer’s requirements.

London Underground operators wanted to find a way to slab track the underground line, between Baker Street and Finchley Road, without closing the line for 2 years.

The machine had to be able to arrive through the oldest metro tunnel in the world, dating back to 1861, to replace the ballast with fast setting concrete, so that trains could pass over it after just two hours.

All the work was carried out at night during the hours of closure of the Tube.

Good knowledge of dosing processes and component mixtures made possible the construction of a mobile railway mixing plant that mixes concrete directly on site with a resistance of 15 MPa within 2 hours, to allow trains to run the same morning, and reaching 65 MPa in 28 days.

The World’s Only Battery-Powered Mobile Concrete Mixing Plant

Safety was guaranteed using barriers (chains and doors) on board, fire extinguishers and signal lights that warn about plant passage in the tunnel. This mobile mixing plant for concrete, on a single railway wagon, was powered by the locomotive’s batteries: this is the first and only one in the world to be powered by batteries. This system reduces fumes and hazards and improves workplace conditions and the health of workers.

From 2016 Blend Plants worked non-stop, producing between 8 to 15 cubic metres of concrete per night. In 2019 the works were completed. Transport for London (TfL) is planning to use the machine in other projects in 2020.

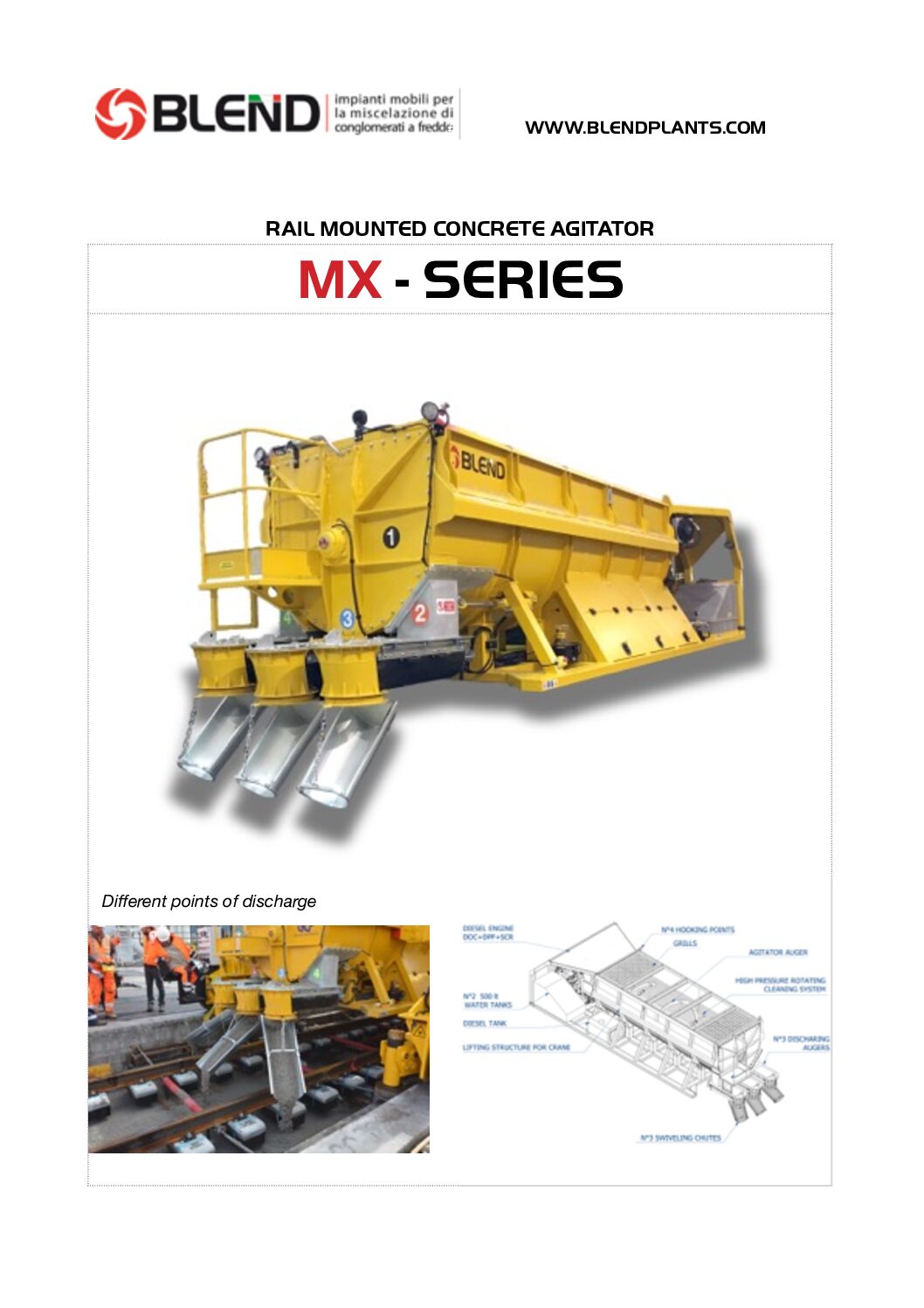

Concrete Agitators for the Ceneri Base Tunnel

Blend Plants took part in another important rail infrastructure project. In 2017, the company supplied six concrete agitators to GCF Spa (Generale Costruzioni Ferroviarie) for the Ceneri Base Tunnel slab track in Switzerland.

The Blend MX08 project was developed in order to satisfy both the safety requirements of the customer and also to guarantee the high and constant quality of the concrete.

The first positive test took place on 28 April 2017 and work began in July 2017. The project brought many challenges: due to the tunnel configuration and the particular concrete laying technique, concrete transport using a traditional drum-type mixer was not possible.

The Blend MX08 was designed with a hopper frame in Hardox to hold 8 cubic metres of concrete and an auger to mix the concrete during transport. Each unit was equipped with three smaller augers and hydraulic pistons to guarantee an even pour on all sides of the rails. The diesel motor delivered a power of 120 Kw, while the high-pressure washing system used two 500 L water tanks.

The agitator was combined with a mobile portal crane, designed by GCF, in order to place the plant right at the point of pouring. Both machines contributed to speed up the works in the tunnel.

Once finished in 2020, this tunnel will reduce the travel times from Milan to Zurich by about 1 hour and 15 minutes.

Nowadays, Blend continues to be a motivated and flexible company with a solid background based on years of experience, always providing new solutions and developing technology together with its customers.