Solutions for Isolating the Permanent Way from the Surroundings: Effective Vibration and Structure-Borne Sound Protection

Mass-Spring Systems

Different design variants as continuous elastic support, stripe or point support perfectly suit the needs and demands for your application. Due to their special design the USM series cover a wide range of natural frequencies and provide high insertion loss for a quiet living close to the track.

The most important benefits are: an expected service life of min. 60 years, no replacement required thanks to high fatigue strength, increased long-term stability for the track position as well as reduction in the dynamic wheel forces.

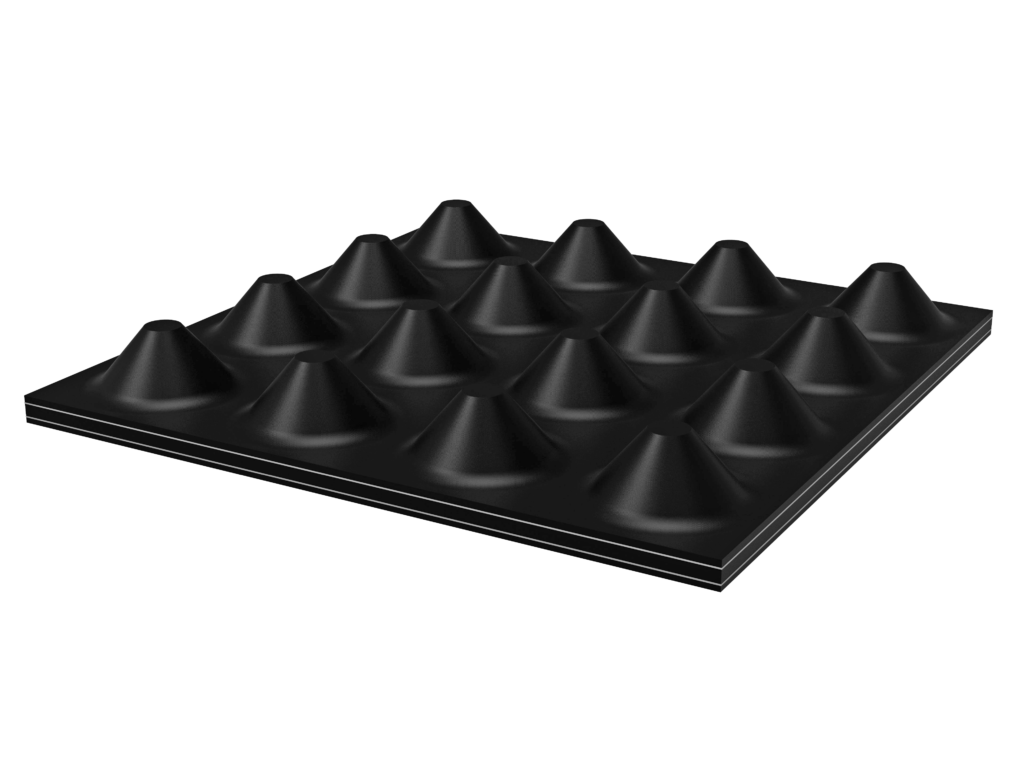

The different USM types consist of three functional layers united in one component. The conical studs on the underside of the mat are made from natural rubber and behave as single springs with an optimum static-to-dynamic stiffness ratio.

The textile fabric reinforced back forms the supporting layer for the studs and the composite component performs as a damping and protective layer that withstands any load impacts just like it does as solid stay-in-place formwork supporting the steel reinforcement cages in the construction of slab track. The mats have an overlapping strip on one of their longitudinal edges to allow effective butt jointing during placement on site.

The USM series complies with DIN 45673 and has been tested and proved by various official testing institutes.

The USM models are manufactured using high-grade rubber blends. They have a high mechanical load capacity and are permanently weather-resistant. The mats absorb virtually no water, excel thanks to their high electrical insulation resistance and provide drainage on the mat level.

The USM series is suitable for nearly all track systems, especially local transport railways and standard-gauge railways.

Recent Projects

Cologne

The KVB looked for an effective technical solution to reduce vibrations and structure-borne-noise at a track triangle on Neusser Strasse in the district of Weidenpesch. Passing trams may cause vibrations which are then transmitted via the ground into the neighbouring residential buildings.

To protect the residents from these disturbing vibrations, a continuous mass-spring system was installed, which supports the turnout on top (floating slab track). For elastic decoupling, approx. 600 m² of Calenberg USM 2020 are used as floor and side mats. The floor mat is laid loosely on the concrete base. The side mat is fixed by means of a Z-profile. A rigid connection between the permanent way and the subfloor is interrupted by the mat. The USM 2020 reduces the dynamic forces acting on the surroundings in such a way that the residents are effectively protected from vibrations

Gera

The intention of the 1st construction phase at Wiesestraße is to obtain a reliable and low-maintenance track system, as hardly any major repairs to the track are possible due to a short cycle sequence of tram traffic. Furthermore, the surrounding buildings need to be protected from shocks and vibrations. In addition to the construction of a new track bed, a continuous mass-spring system is being built in this planning area. An elastic track bed mat will be used for the floating slab track, which will also serve as stay-in-place formwork. The implementation of the project is planned in time shifted construction phases, the completion of which is expected by the end of 2022.

The track support plate of the carriageway is mounted on Calenberg USM 1000 W as a floor mat. As this is a straight track section, the mat is installed longitudinally to the track. Civerso is used as the side mat, which also provides a flexible solution to efficiently cover the numerous drainage boxes within the rail roadside.

Some of the advantages are:

- The profiling ensures all over drainage underneath the mat, no water absorption of the mat

- Shortened installation time due to longitudinal laying

- Concreting of the track support plate directly on the mat

For more information visit www.calenberg-ingenieure.com or contact [email protected].