For over 100 years, Harsco Rail has worked continuously to help railways stay on track by meeting the demands of tomorrow, today.

The result: lower operating costs, higher speeds and – most importantly – improved safety.

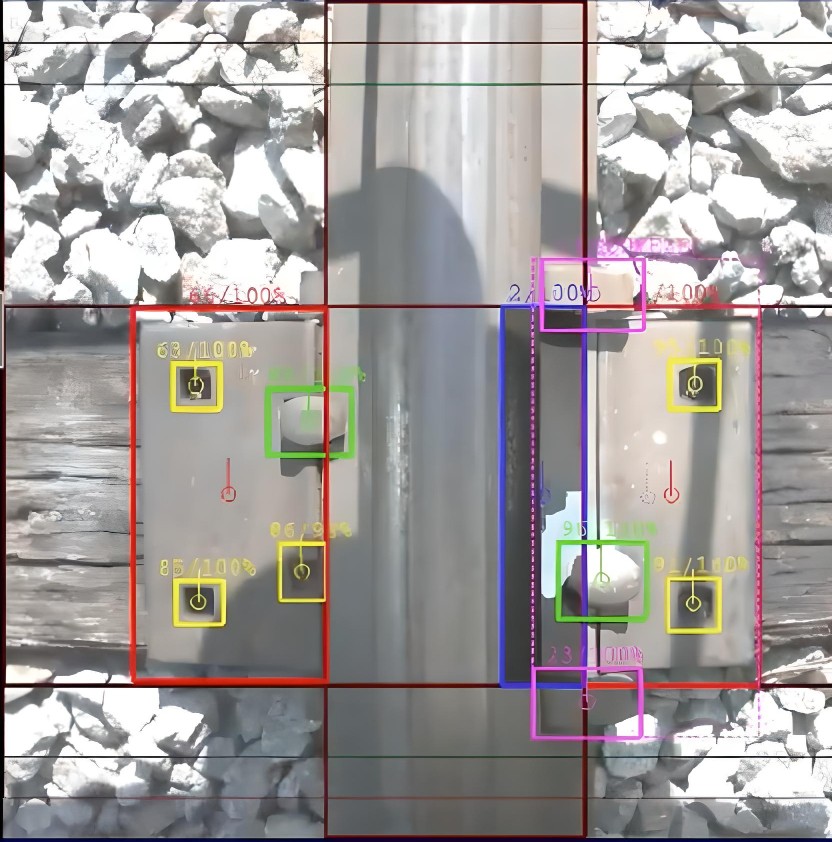

Improving the rail grinding product lines is an on-going process at Harsco, where grinding machines utilise a common control system that allows for different configurations, depending on the customer’s needs. On-going development of its Jupiter control system allows the company to respond to custom specifications and global requirements.

Harsco’s C model grinders have been improved to the point that the life-span of high-wear parts, such as grinding motors, exceeds five years; the life-span of head actuators exceeds ten years. A new, higher-horsepower grinding motor, which has increased metal removal rates at higher grinding speeds on its larger grinders, has a life-span 3 to 5 times longer than the previous generation of grinding motors.

The life-span of the stone a further consideration. Longer- lasting stones typically remove less metal, impact surface finish, and increase overall cost. Years ago, developing grinding stones was a necessity. While Harsco continues to test and improve grinding stones, the advanced control system on the latest grinders is better able to control stone positioning and behaviour in order to obtain a high metal removal rate from one type of grinding stone, then use the same stone to meet a stringent surface finish requirement.

The company said:

“We can also introduce slightly different head lateral shifts independently, which helps control acoustic noise on light rail metros or transit systems.”

Harsco Rail said:

“Performance and efficiency are essential, but safety is the most important factor to consider.”

Over the years Harsco has improved spark- containment, fire-detection, fire- extinguishing, dust-collection, and operator-safety systems, along with systems that are easier to operate and troubleshoot, overall.

The company said:

“We have designed to some of the most demanding EN and customer-specific standards.”

Most of the grinding equipment incorporates sealed cabins that control dust and hold noise levels to 68dBa.