GSF Rail Infra b.v. is proud and pleased to announce that ProRail has allowed our SoundSafe Movable to pass through to the final implementation phase of the Innovation Partnership Noise Barriers.

This means that the SoundSafe Movable has been fully tested and is approved by ProRail for use along the track. All acoustic, technical, financial, environmental and many other requirements have been fully met. Therefore, the SoundSafe Movable will now be used in the Netherlands. This makes the SoundSafe Movable the first approved Dutch mini noise barrier that will be used to reduce noise pollution without impeding the view of residents who live near the track.

This type of screen was developed as part of the Innovation Partnership for Sustainable Noise Barriers that ProRail has entered with several parties. The partnership was funded by the Ministry of Infrastructure and Water Management, the participating parties and ProRail.

In the coming months, ProRail will choose a location where we will install the first 125 linear metres as a part of the Multi-Year Programme for Noise Remediation (MJPG).

About the SoundSafe Movable

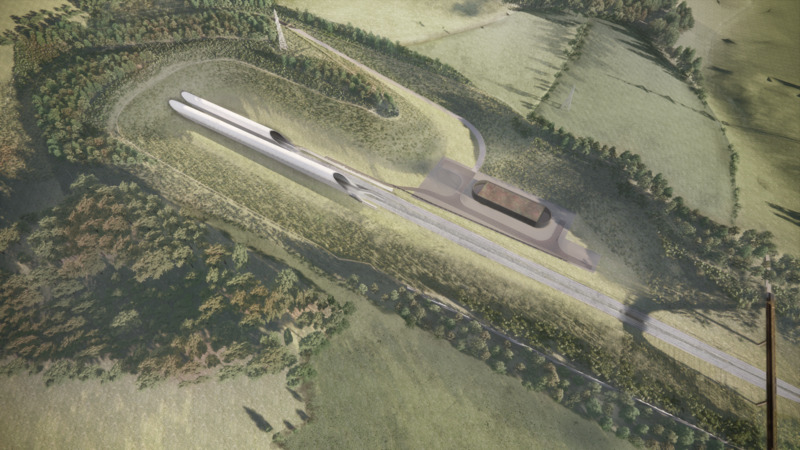

The SoundSafe Movable is a new type of mini noise barrier. This highly absorbent noise barrier, positioned close to the noise source (train wheels), is only 76 cm high, measured from the rail. As a result, the screen has minimal impact on the surroundings and the views of local residents. Their lines of sight are not disturbed by the SoundSafe Movable, and there is no annoying shadowing.

The SoundSafe Movable has successfully completed the Innovation Partnership Sustainable Noise Barriers. To enable this, the thrust pressure of trains on the screen was determined for the structural validation using CFD calculation models. The SoundSafe Movable therefore demonstrably meets all requirements. Furthermore, the cost per metre is comparable to regular noise barriers.

Thanks to our innovative foundation and supporting structure, this mini screen can be installed without affecting the railway track and embankment and with minimal impact on subterranean infrastructure. The support structure makes it possible to easily fold the screen away during maintenance on the track. As a result, this type of screen can be used almost without restrictions to maintenance. The installation process is rapid. Per 8 hour shift using two (rail)cranes, about 100 to 120 meters of screen can be installed, including foundation and support structure.

The screen has a very high sound absorption which eliminates noise very effectively. In many locations it offers a direct alternative to regular 2.5- or 3.0-meter-high noise barriers. This has been substantiated by independent practical acoustic tests carried out by engineering firm DGMR b.v.

The 7.5-metre-long wooden panel (weight approx. 400 kg each) made of Canadian Larch is treated with a highly innovative lifelong fire retardant and just like the support structure, has a maintenance-free lifespan of 50 years.

The construction can be completely dismantled and the panel, including the fire retardant, can be composted at the end of its lifespan. The foundations can be easily removed and even reused if desired. The Environmental Cost of the SoundSafe Movable is very low, about 35% of a reference aluminium noise barrier.

Are you interested in a mini noise barrier for your project or town? Or if you are interested in a cooperation or a license? Please feel free to contact us at [email protected].

This article was originally published by GSF RailInfra.