Wherever there’s advanced rail technology, you’ll find Cummins power.

Under the floor on Europe’s high-speed passenger trains. On 20t grinders in the Far East. Cummins is on track with the most progressive rail companies in the world, including Bombardier and Siemens.

We offer a full line of ratings, with many engine models specifically modified for railway equipment. Cummins railcar engines, for instance, utilise low-profile designs for use under the car floor, with access to service points from underneath the engine, not inside the passenger compartment. The 750-hp QSK19 is the newest of our ‘horizontal’ engines, and has the capacity to drive a new generation of high-speed DMUs, with projected speeds of up to 210km/h.

For locomotive power, Cummins offers a comprehensive range of high-performance, low-maintenance diesels to meet your needs. 12 different engines are available in a wide range of horsepower, including V12 and V16 configurations. With ratings of up to 2100 rpm, these engines are more fuel efficient, more space efficient, have longer service intervals and a higher power-to-weight ratio than low-speed units.

Low cost-of-operation and high dependability also make Cummins engines ideal for track maintenance equipment. We know that for the trains to run on time, you have to keep your tracks up to speed – every day.

Cummins also knows that trains don’t move unless people get training. That’s why we offer specialist service training for operator personnel at our international training centre in Daventry, England.

A Better Train of Thought

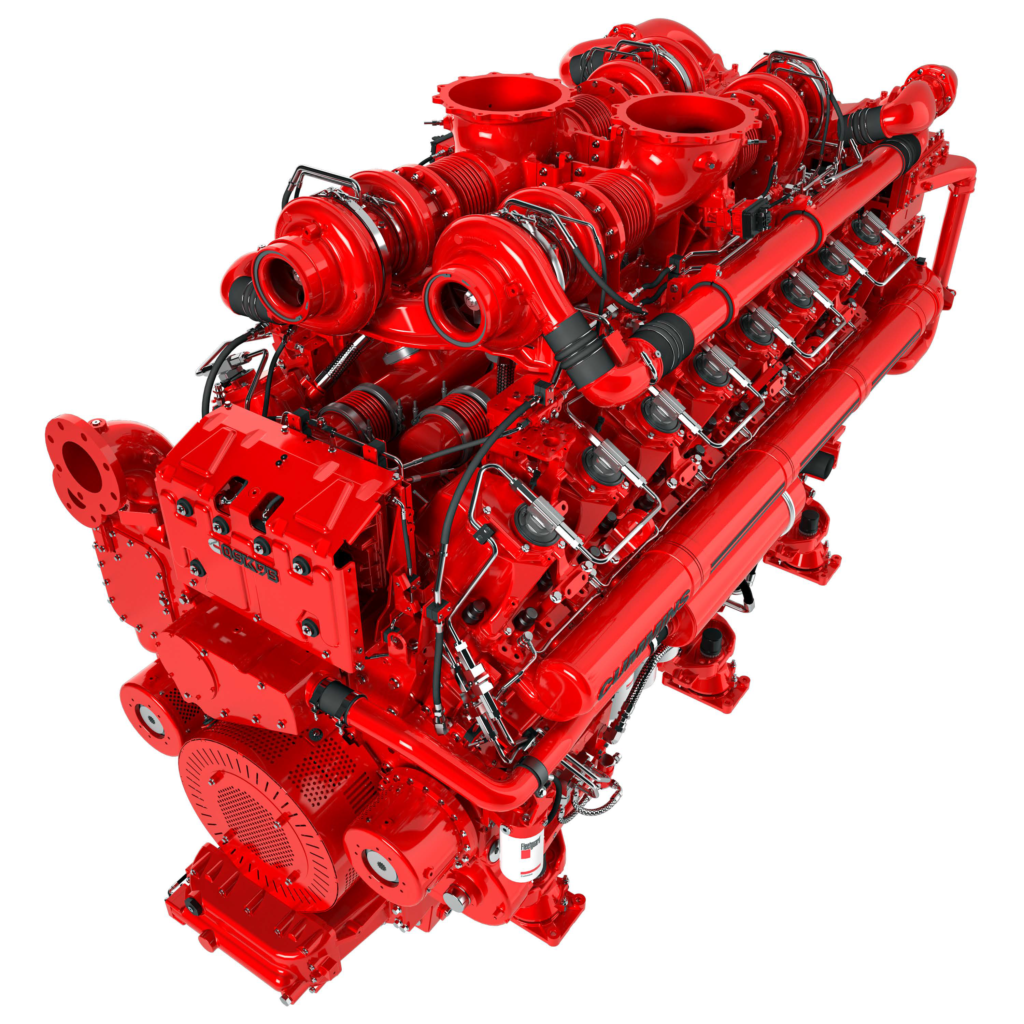

For locomotive builders looking for a new-power approach to achieve cleaner, more efficient performance, the QSK95 engine arrives on time to deliver radically improved power capability for both freight and passenger operations.

With over 4000-hp (2983 kW) output from 16 cylinders, the QSK95 surpasses other high-speed engines. In terms of emissions capability and compact installation, the QSK95 is way ahead of much larger medium-speed engines with a similar output.

High power density, together with Cummins space-saving exhaust after-treatment, creates a lighter, fully integrated emissionised power solution designed to meet all of the requirements for new high-speed passenger locomotives. Operators of multi-purpose freight locomotives from 3600 hp (2684 kW) will find the QSK95 a cost-effective and very dependable power solution – keeping train operations on schedule.

The QSK95 delivers even more fuel savings to line-haul freight applications when used together with a smaller Cummins locomotive engine for full pulling power when you need it, and the best-possible fuel economy at lower power levels. A smart power-sharing system transfers work between the two engines to match the locomotive duty cycle, so that overall fuel and operational costs are significantly reduced – an advantage that represents a better train of thought over current conventionally powered locomotives.

The Cummins exhaust after-treatment system is purpose-designed for locomotive installations, using Selective Catalytic Reduction (SCR) technology. This unique, modular system minimises space claim and improves fuel efficiency, lowering the overall cost of operation. Without exhaust after-treatment, the QSK95 engine meets Tier 3 locomotive emissions and is ideally suited for locomotives operating anywhere in the world, however tough the conditions. The engine is built ultra-strong for this purpose, with very long life-to-overhaul offering a major reduction in total life-cycle costs.

The space-efficient design of the QSK95 enables easier service accessibility than is typical for engines of this output, as all key cooling, oil and fuel system components are externally engine-mounted, providing rapid access.