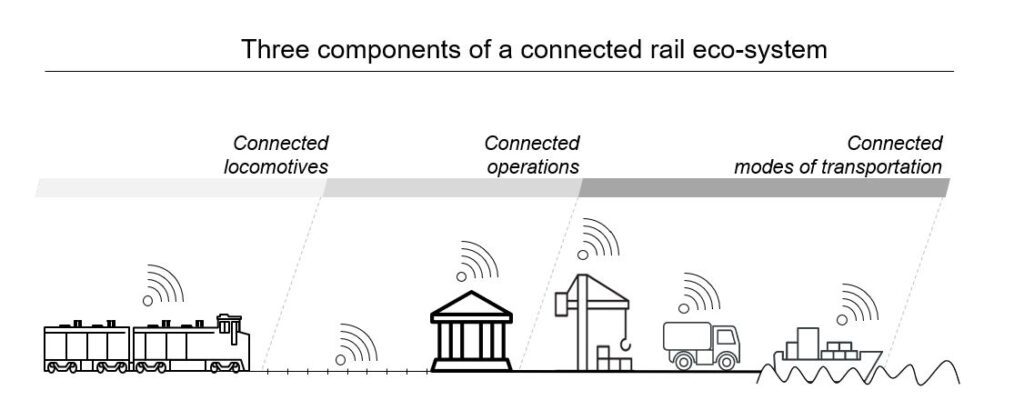

Three Components of a Connected Rail Ecosystem

- By Aytek Yuksel, Content Marketing Leader – Power Systems

With 200 billion Internet of Things (IoT) objects humankind has today1, connectivity is embedded at every aspect of our lives. When it comes to connectivity within the transportation sector, highway vehicles such as cars, trucks and busses get the spotlight; yet one would think whether trains would be a better candidate to adopt connected solutions given some aspects of operating trains is less sophisticated.

For instance, operating an individual train, in comparison to operating highway vehicles, features less variables in terms of other moving vehicles on the tracks and different routes to take. Trains move on set tracks and in one direction, often without a significant number of intersections. Meanwhile, creating a connected rail ecosystem goes beyond the individual trains. In this article, you can find the key components of a connected rail ecosystem, and what the future relies on in each of these.

No. 1: Asset-Level Connectivity; Connected Locomotives

While the physical look of locomotives has not drastically changed over the last decade, what is beneath that initial look has been constantly changing. Today’s modern locomotives feature hundreds of sensors; these sensors do a variety of tasks ranging from tracking internal attributes such as level of consumables, to external attributes such as wind speed and direction.

Moreover, many of these connected solutions go beyond just the reactive monitoring. For instance, PrevenTech® Rail, the remote engine monitoring solution by Cummins, delivers proactive recommendations that allow customers to increase equipment availability, improve safety, and enhance operational efficiency.

The future of asset-level connectivity relies heavily on integrating stronger artificial intelligence and machine learning into the already existing network of sensors. This integration will make each locomotive capable of predicting future issues, then execute over-the-air updates or schedule needed preventative maintenance.

No. 2: System-Level Connectivity; Connected Operations

At the system-level, the focus moves from individual components such as locomotives and railcars to managing the complete rail network and the fleet, whether it is freight or passenger focused. This includes better utilization of rail equipment through scheduling and integrating connectivity established through different elements of the network such as locomotives, stations and tracks.

The future of system-level connectivity is on the ability to harness the data each connected equipment brings on to maximize the efficiencies and safety while lowering costs. For instance, the sensors on a station could track the number of passengers waiting, and communicates this information to the upcoming train. Meanwhile, a third sensor located in between the inbound train and the station could communicate a weather event, requiring the station to dispatch another train. In this example, data from three different assets can be harnessed in real-time. The key enabler for this to work efficiently will be the networking technologies that can harness the data collected, and the computing capabilities that can process the data to create actionable recommendations.

No. 3: Intermodal Connectivity; Connected Modes of Transportation

Whether it is passenger or freight focused, rail transportation often is coupled with other transportation modes. Someone might need to take the bus to go to the train station, or containers carried by trains to a depot may require trucks to carry them to their next stop.

Intermodal connectivity entails the integration of adjacent non-rail transportation networks into the connected operations of a rail network. Here’s the good news; much of this non-rail network (air, marine and on-highway based) have also advanced in building their own connected operations within their systems.

The future of intermodal connectivity will be not only technology driven, but also collaboration driven. Unlike the asset and system-level connectivity, rail operators will get out of the boundaries of their businesses and build deeper collaborations with other transportation companies to bring intermodal connectivity to life.

The future of rail is connected, and a combination of emerging technologies, skills and partnerships lay the path to this connected future. The good news for rail operators is the presence of partners they can collaborate with, such as Cummins Inc. that can extrapolate connectivity learnings from many other transportation markets into the rail sector.

- References: 1 Intel. (n.d.). A Guide to Internet of Things [Infographic]. Retrieved from https://www.intel.com/

This article was originally published by Cummins Inc..