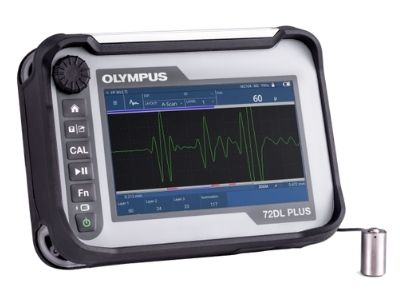

Why create a brand new ultrasonic flaw detector when the EPOCH® 650 instrument works so well? This is one of the first questions we were asked when we pitched what would become the EPOCH 6LT portable flaw detector.

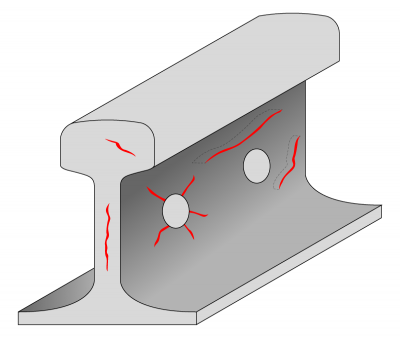

Talking with our customers, we learned just how many of them work in rope access applications or require an ultra-portable instrument that is lightweight, easy to carry, and fits in a travel bag with other equipment. While the EPOCH 650 flaw detector is great at most conventional ultrasonic (UT) applications, it would be difficult to carry it up 200 feet and hang off the side of a wind tower. For rope access applications in particular, some customers were using the EPOCH LTC flaw detector, but they had to adapt the instrument to suit their work-at-height applications. In some cases, they were even taping the instrument to their leg!

This convinced us of the need for an instrument designed for rope access and high portability applications.

Developing a New Flaw Detector

When we were developing the new instrument, we started calling it ‘Helium’ to remind ourselves that it had to be lightweight. We set an ambitious goal—deliver an instrument that has all the core functionality of the EPOCH 650 flaw detector in a rugged, light, and ergonomic package optimized for rope access and high-portability applications.

First, we talked to rope access technicians and asked what they wanted in a flaw detector. They wanted a powerful instrument suitable for the majority of conventional UT applications. They also wanted to be able to attach the flaw detector to their leg or harness so they could remain focused on their top priority, safety.

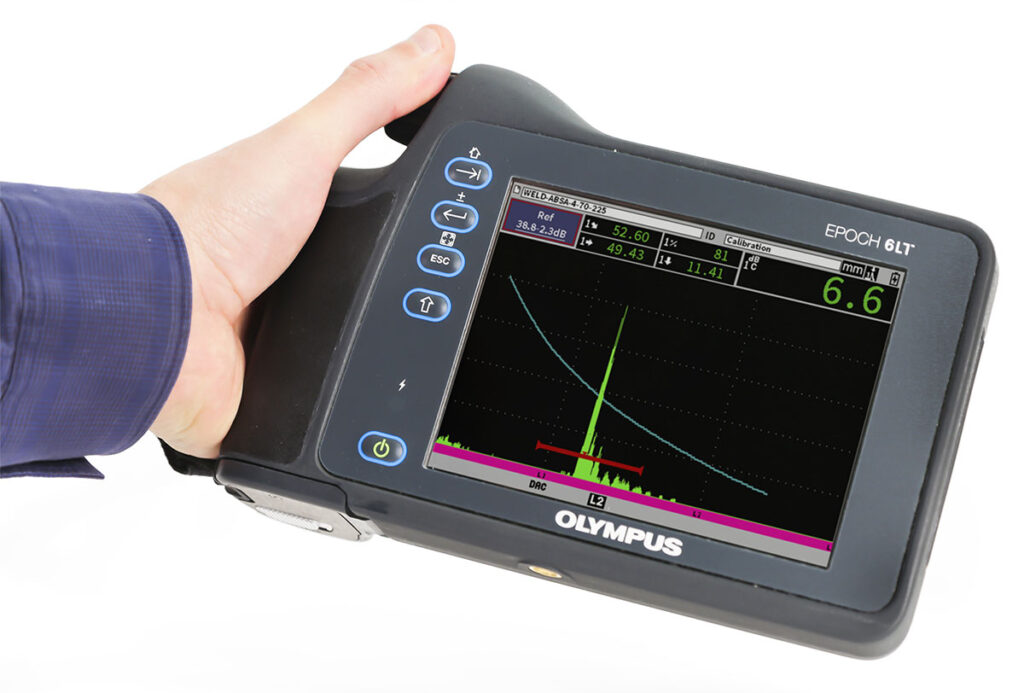

Talking with our high-portability customers, they told us that they preferred a flaw detector they could hold securely in one hand. Wrist fatigue was a major concern, so they wanted something they could hold comfortably for long periods of time. Some of these customers need to monitor for corrosion in applications like in-service pipe inspection, so adding this functionality was also important. Lastly, they wanted the device to be small enough that it could fit in a bag with other equipment.

All of our customers wanted a flaw detector with a big, bright screen that was readable in any lighting condition. Since these instruments are going to be used in places like oil rigs, pipelines, and bridges, it also needed to be rugged.

Throughout the design process, we kept these customer requests at the forefront. We worked to create an instrument that excelled in three areas: ergonomics, functionality, and versatility for rope access users. The result is a device that delivers what our customers told us they wanted.

Ergonomics

The EPOCH 6LT flaw detector is designed with an ergonomic handgrip and strap, so that it sits comfortably and securely in your hand. We then optimized the entire instrument for one-handed operation. The flaw detector weighs only 1.95 pounds (890 grams). We shifted the center of gravity toward the handgrip, making it easier to hold and minimizing wrist fatigue. We added a rotary knob and positioned it so you can easily scroll through the software’s menu using just your thumb. Four raised buttons are readily accessible, making it easy to control the device with one hand while scanning for flaws, even when wearing gloves. We added a bright transflective screen with an outdoor mode that delivers clear, readable A-scans in any lighting condition. It’s also rugged; it’s engineered to IP65/67 and drop tested to help ensure more uptime.

Once we addressed the comfort and ergonomics of the instrument, we added all the core functionality of the popular EPOCH 650 flaw detector, including a powerful pulser, a digital high dynamic range receiver, and EN12668-1:2010 compliance. We simplified the software’s user interface for one-handed operation—the two screen, icon-based interface makes navigation quick and easy. For users who need to scan for corrosion, we created optional corrosion software that combines the ease of use of a thickness gage with the flexibility of a flaw detector. We also added a popular thickness gage feature, center-pin transducer ID, for faster set up.

The EPOCH 6LT flaw detector is also our first UT instrument to offer Wireless LAN connectivity. In conjunction with the Olympus Scientific Cloud, Wireless LAN enables on-the-go data backups, setup downloads, efficient fleet management, and powerful cloud applications.

Versatility for Rope Access Applications

We know that rope access technicians have special requirements. The rope access accessory kit turns the EPOCH 6LT flaw detector into a powerful instrument for work-at-height applications with features that help inspectors stay safe. The flaw detector fits snugly in a protective case that can be securely attached to a user’s leg with the strap or fastened to a user’s harness connection points with two adjustable safety leads. No matter how it’s secured, the instrument remains in a comfortable viewing position.

With the unit secured, it’s easy to adjust the flaw detector with one hand, leaving the other free to maneuver the transducer or maintain balance and personal safety. The inspection display can be viewed in either portrait or landscape mode, depending on how it’s attached, for optimal A-scan viewing.

We designed the EPOCH 6LT flaw detector so that users don’t have to compromise comfort and ergonomics to get the ultrasonic performance they need to get the job done. Want to see the EPOCH 6LT flaw detector in action? Check out this video.

This article was originally published by OLYMPUS.