Inspection, Testing, and Measurement Solutions for Railway Infrastructure and Rolling Stock

Rail travel is a key part of the transportation industry for its speed, reliability, and affordability. With a large, ageing infrastructure, railways require constant support to maintain their integrity and operate safely and efficiently.

A Complete Workflow Solution

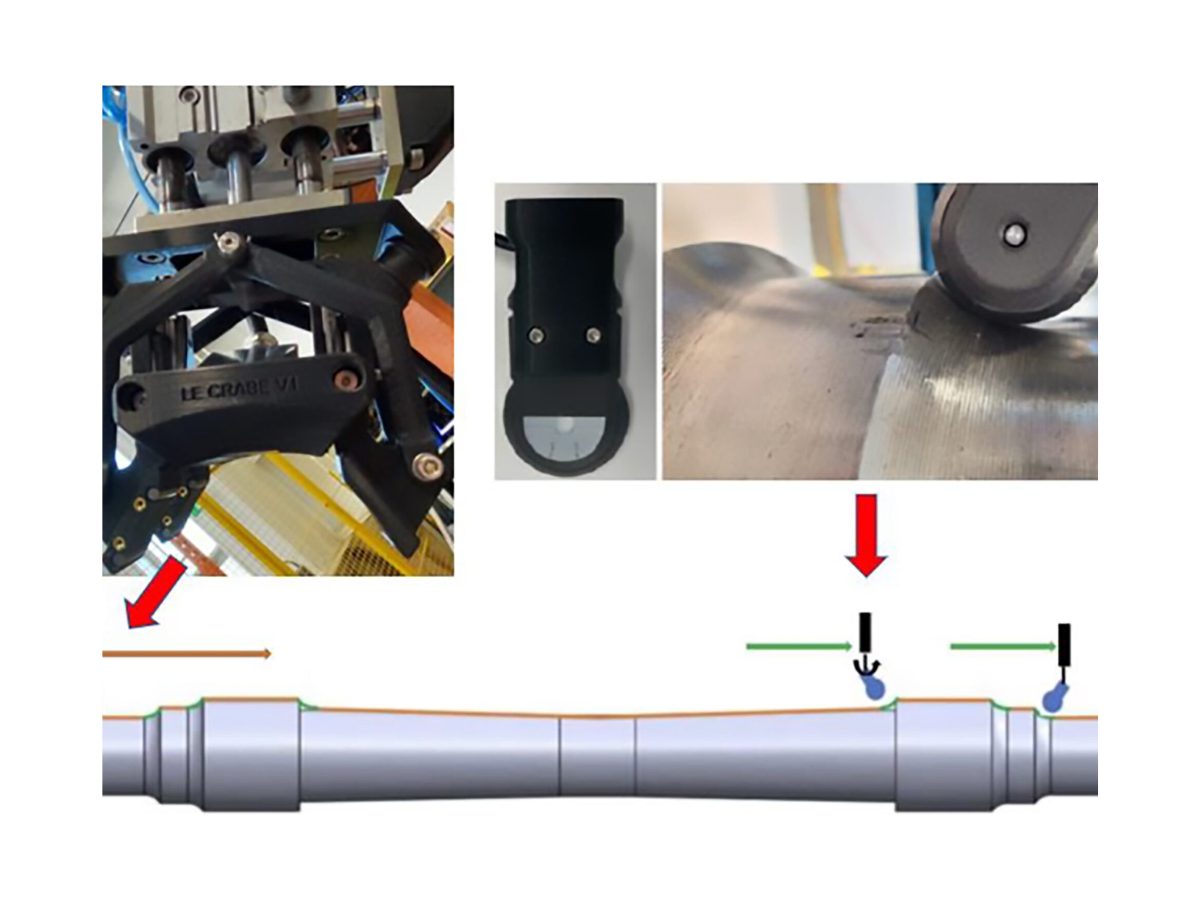

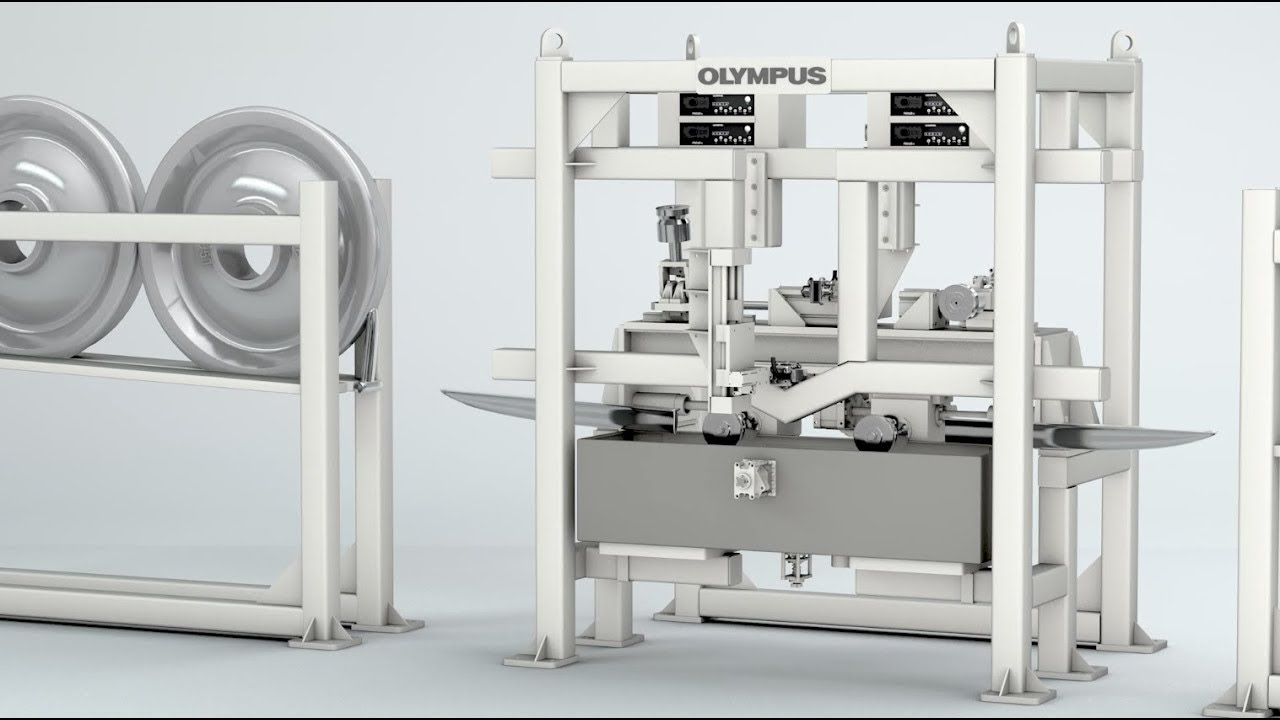

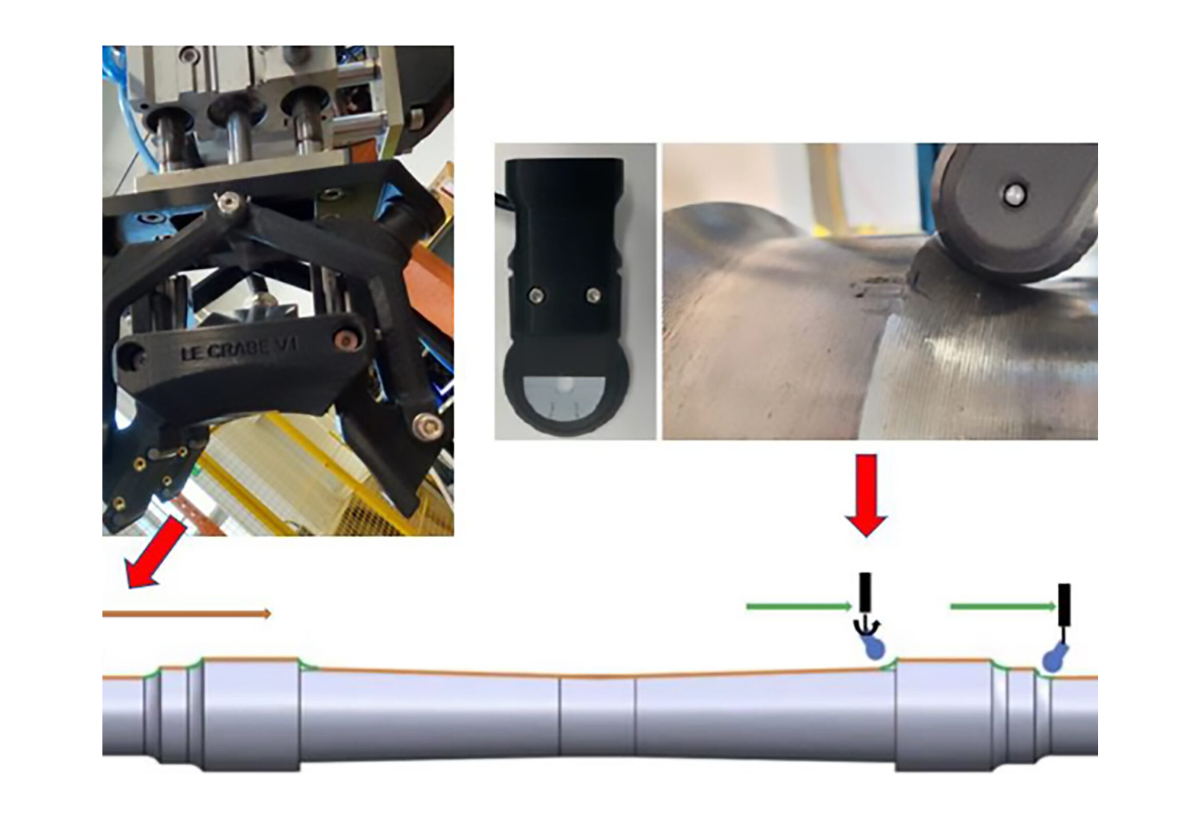

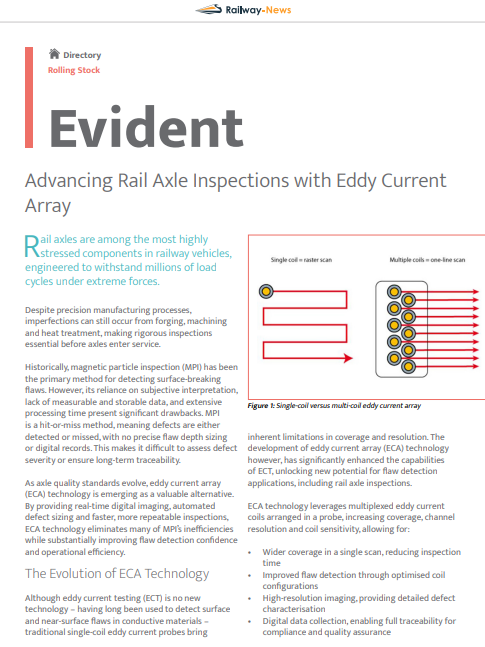

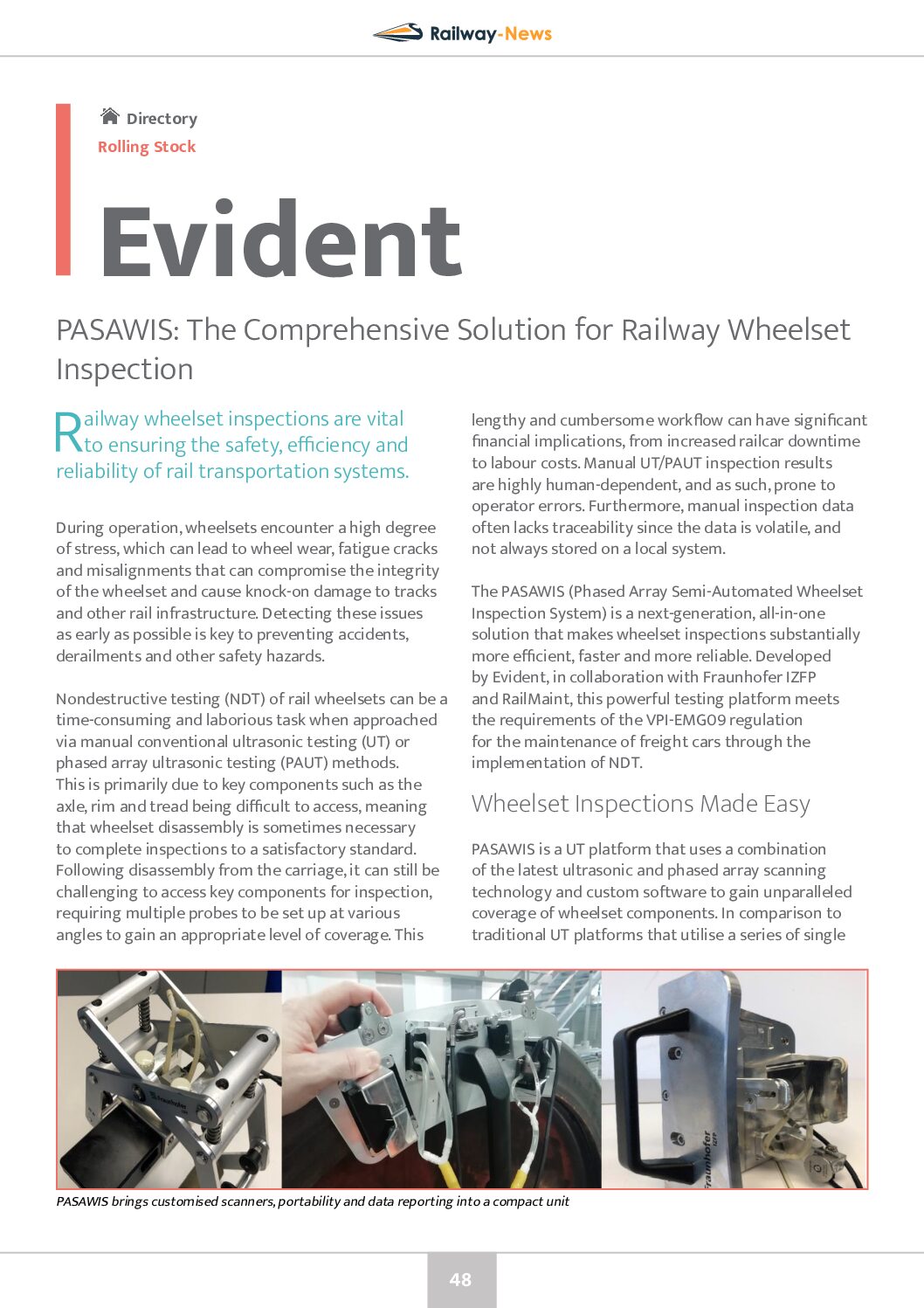

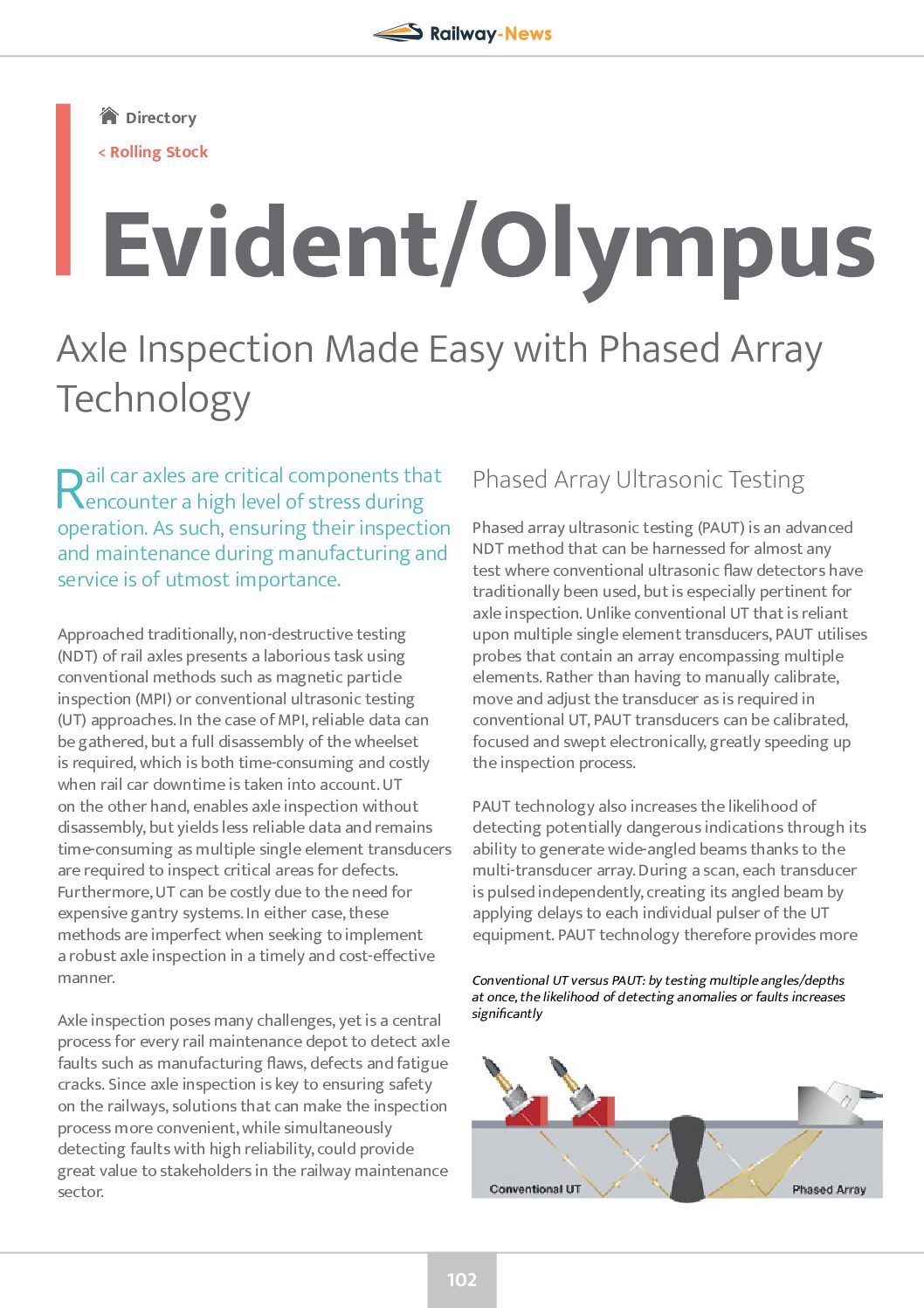

Inspecting the integrity of the rails as well as train vehicles, wheels and axles for flaws is essential to keeping rail networks operating. Non-destructive testing (NDT) technology, including conventional and phased array ultrasound, and eddy current array, is used to inspect trains and rails during manufacturing and as part of a regular in-service inspection program to help keep railroads on track.

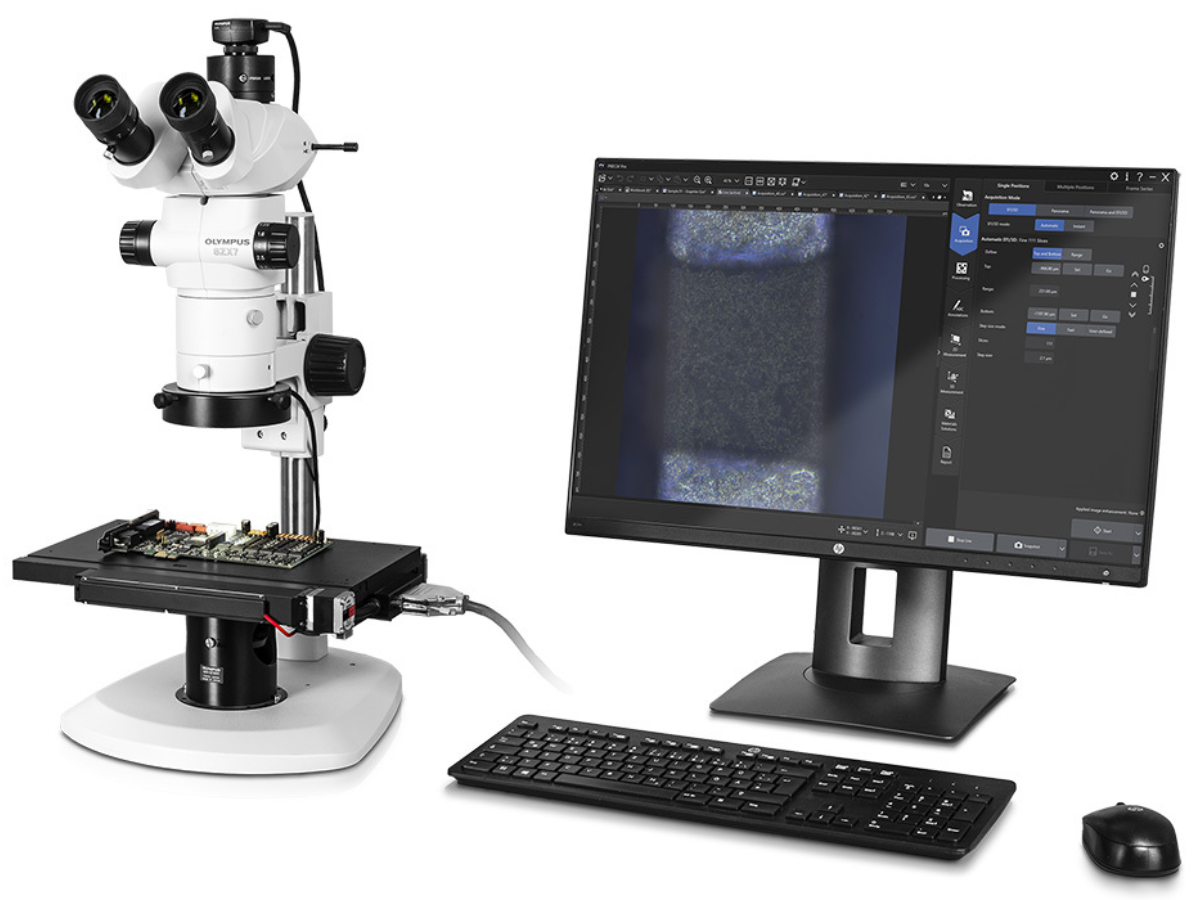

Evident provides a wide range of solutions from portable, off-the-shelf units through to large scale, integrated systems. A comprehensive portfolio also includes remote visual inspection, materials microscopy and X-Ray fluorescence technologies.

Evident solutions are used for a wide range of applications both in the rail industry manufacturing and maintenance sectors. Focussing on applications such as vehicle, axle and wheel inspections, rail infrastructure integrity checks (rail welds, cracks, defects, as well as switches), and rolling stock investigations such as windshield bond testing.

Extensive Capabilities

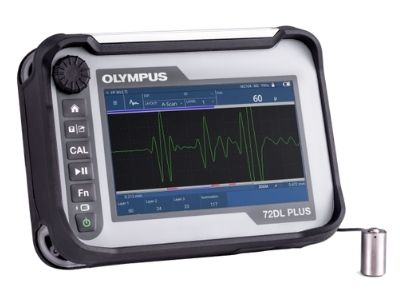

Technologies range from handheld thickness gauges to verify if components or systems are within limits/tolerance, or to verify wall loss due to corrosion or general wear and tear, through to comprehensive production line installations.

About Evident

Olympus Scientific Solutions is now Evident. As a global solution provider, Evident works with rail operators and manufacturers to provide added value technologies, ensuring users can rely on fast, accurate and repeatable results supported by advanced reporting and simplified data management and fleet management through the Olympus Scientific Cloud. Extensive service and calibration facilities around the world ensure maximum uptime such that critical testing and measurement needs are met.

Key Products

- 27MG/45MG/38DLP/72DLP Ultrasonic thickness gauges

- Epoch 6LT/650 Ultrasonic flaw detectors

- Nortec 600 Eddy Current flaw detector

- Bondmaster 600 Bond testing flaw detector

- OmniScan SX/X3 Phased Array flaw detectors

- OmniScan Eddy Current Array flaw detectors

- Focus PX Phased Array Flaw Detector for integrated/automated inspections

- Manual and automated NDT scanners

- Ultrasound, phased array, eddy current, eddy current array probes

- IPLEX remote visual inspection videoscopes

- Vanta XRF handheld analysers, and XRD

- Materials microscopy systems including stereo, measuring, digital and laser confocal