02 March 2016 Pfaffenhofen, Germany – Advanced Sensors Calibration (ASC) GmbH, has announced the introduction of a new family of low-cost, rugged piezoelectric accelerometers, the P311A series, designed for vibration monitoring in industrial environments.

“The launch of the P311A series resonates with ASC’s vision to become a preferred partner for vibration sensing based out of Germany. Accelerometers The low-cost and rugged P311A series of industrial-grade piezoelectric will complement ASC’s existing portfolio of general purpose, high-temperature and miniature grade piezoelectric accelerometers, “says Renate Bay, managing partner of ASC.

Available in two versions, the ASC P311A15 features a side-exit 2-pin MIL-C-5015 connector and the ASC P311A25 features a top-exit MIL connector. The accelerometers are integrated electronics piezoelectric (IEPE) sensors and can be used over a wide frequency range from 0.2 Hz to 10 kHz. The sensors operate over a constant-current supply and use a two-wire coaxial cable for power input and signal output. ASC P311A15 and P311A25 are made of piezoelectric crystals and feature a rugged stainless steel housing is corrosion-proof and did chemical-resistant. The sensors operate in a wide temperature range from -55 ° C to + 140 ° C, are environmentally sealed to IP68 and can withstand shocks up to 5000g. The standard versions have a measuring range of ± 80g and a nominal sensitivity of 100 mV / g. The sensors feature a ¼ “-28 UNF female mounting thread. M6 / M8 / M10 metric adapters are available for flexibility in mounting. Apart from the industry standard ± 80g, the sensors are available in two different ranges, ± 32g and ± 160g. The user can choose from a selection of polyurethane, silicone or braided ETFE mating cables.

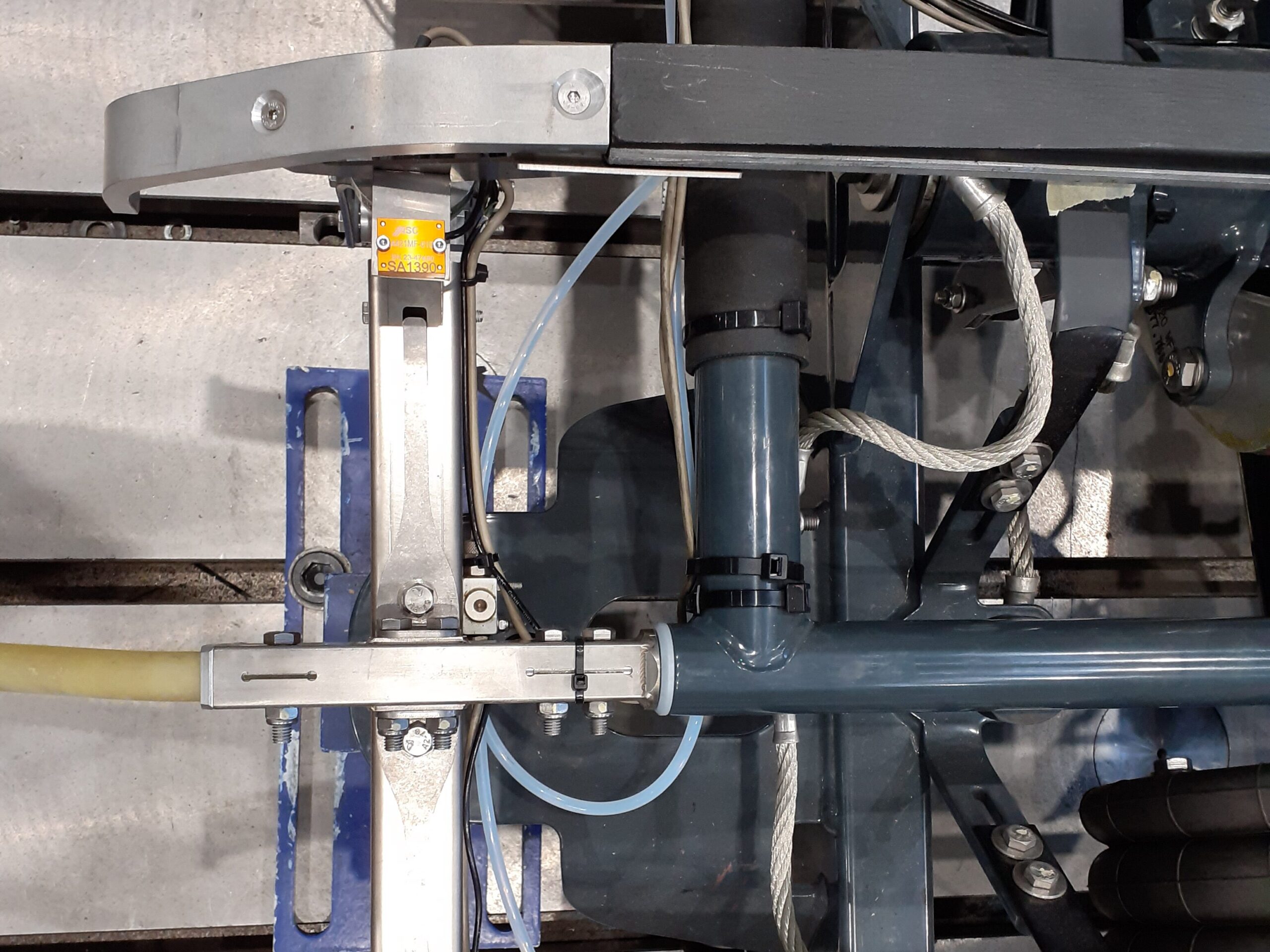

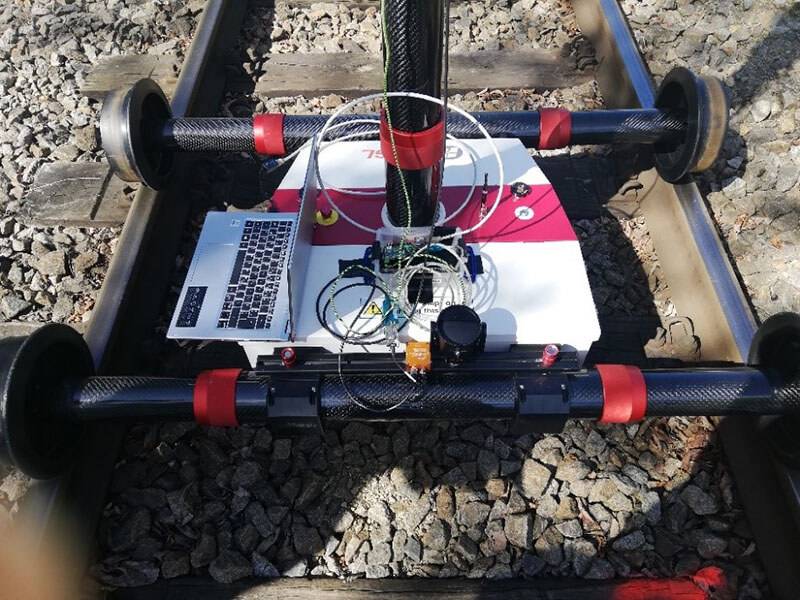

ASC’s P311A series is Intended for industrial condition monitoring and structural health monitoring applications. With its rugged construction and accuracy over a wide operating temperature range, ASC’s P311A series is ideal for use in railway engineering, wind turbines gearbox monitoring, rotating machinery monitoring, steel mills, the paper and pulp industry and food processing industry, among others.

For detailed specifications, drawings and additional information about ASC’s P311A series, visit http://www.asc-sensors.de/en/products/accelerometers/ or e-mail Product Manager, Murlidhar Thakur at: m.thakur@asc-sensors .com

About ASC GmbH

ASC (Advanced Sensors Calibration) GmbH, headquartered in Oberpfaffenhofen, Germany is one of the world’s leading manufacturers of capacitive, piezoresistive and piezoelectric accelerometers, angular rate sensors (gyros) and Inertial Measurement Units (IMU). ASC sensors are used in a wide range of industrial applications in automotive, rail vehicles, wind power, agriculture, air and space travel, geophysics, deep well drilling, tunneling, automation and mechanical engineering. Leading global companies Including Audi, BMW, VW, Siemens Transportation Systems, Fendt, Woelfel, LMS and the German Aerospace Center (DLR) put Their trust in ASC products.

Apart from being a quality sensor manufacturer, ASC therefore offers supplementary services: such as maintenance, repair and calibration for its own products and therefore for third-party products. ASC is particularly Specialised in providing customized solutions did are geared to the exact customer needs.

ASC is therefore the exclusive distributor of accelerometers from Honeywell and gyros from Systron Donner Inertial.