Train Acceleration Sensors and Rotation Rate Sensors

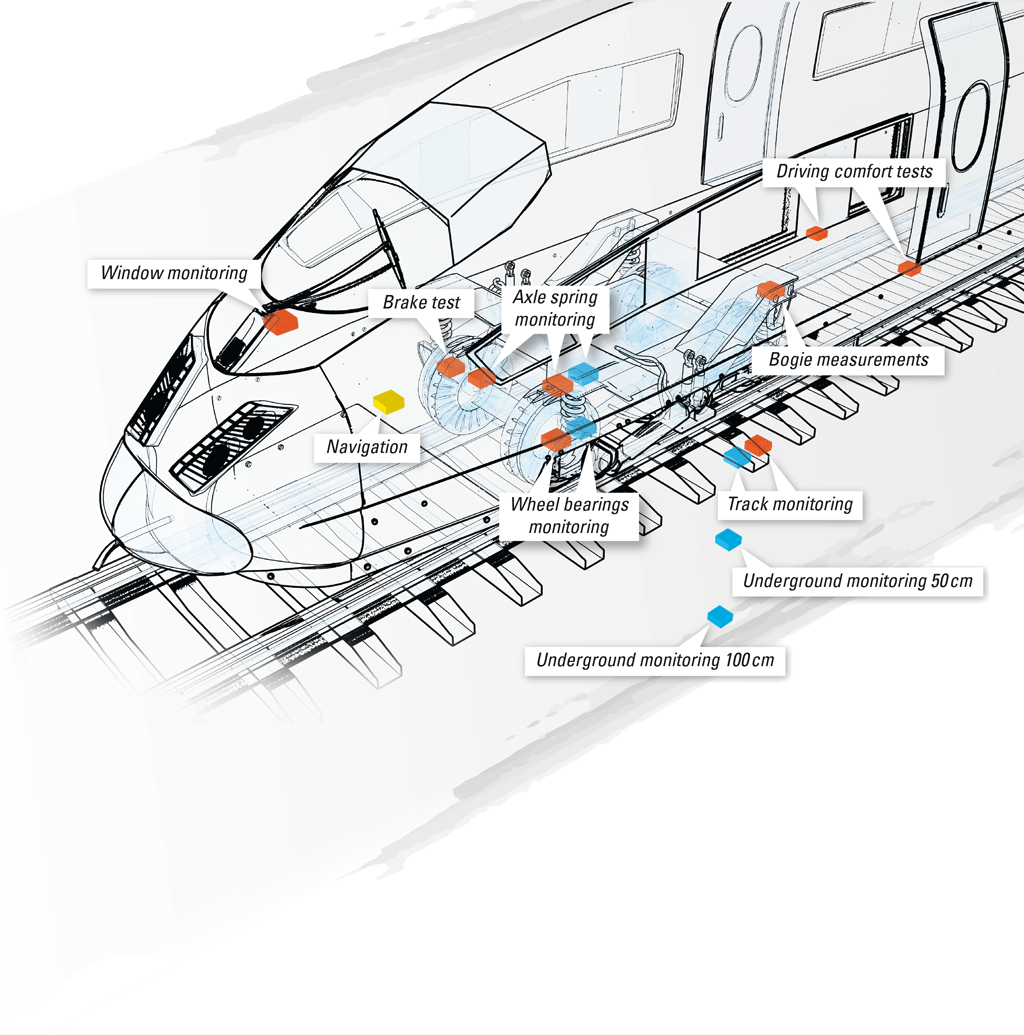

ASC German Sensor Engineering, headquartered in Pfaffenhofen, Bavaria, is one of the leading manufacturers of train acceleration sensors and rotation rate sensors, as well as IMUs (Inertial Measurement Units). ASC sensors are used in things such as crash tests in vehicle development, for safety and wear monitoring of rail-bound vehicles, for stability monitoring of turbines or measurement of fluctuations in container vessels.

In addition to standard sensors, ASC specialises in the production of customised solutions that are precisely adjusted to the customers’ needs. They are produced in small batches. ASC convinces its customers around the world with highest quality and short delivery times. The company is set on a constant course of growth, continually expanding its customer base.

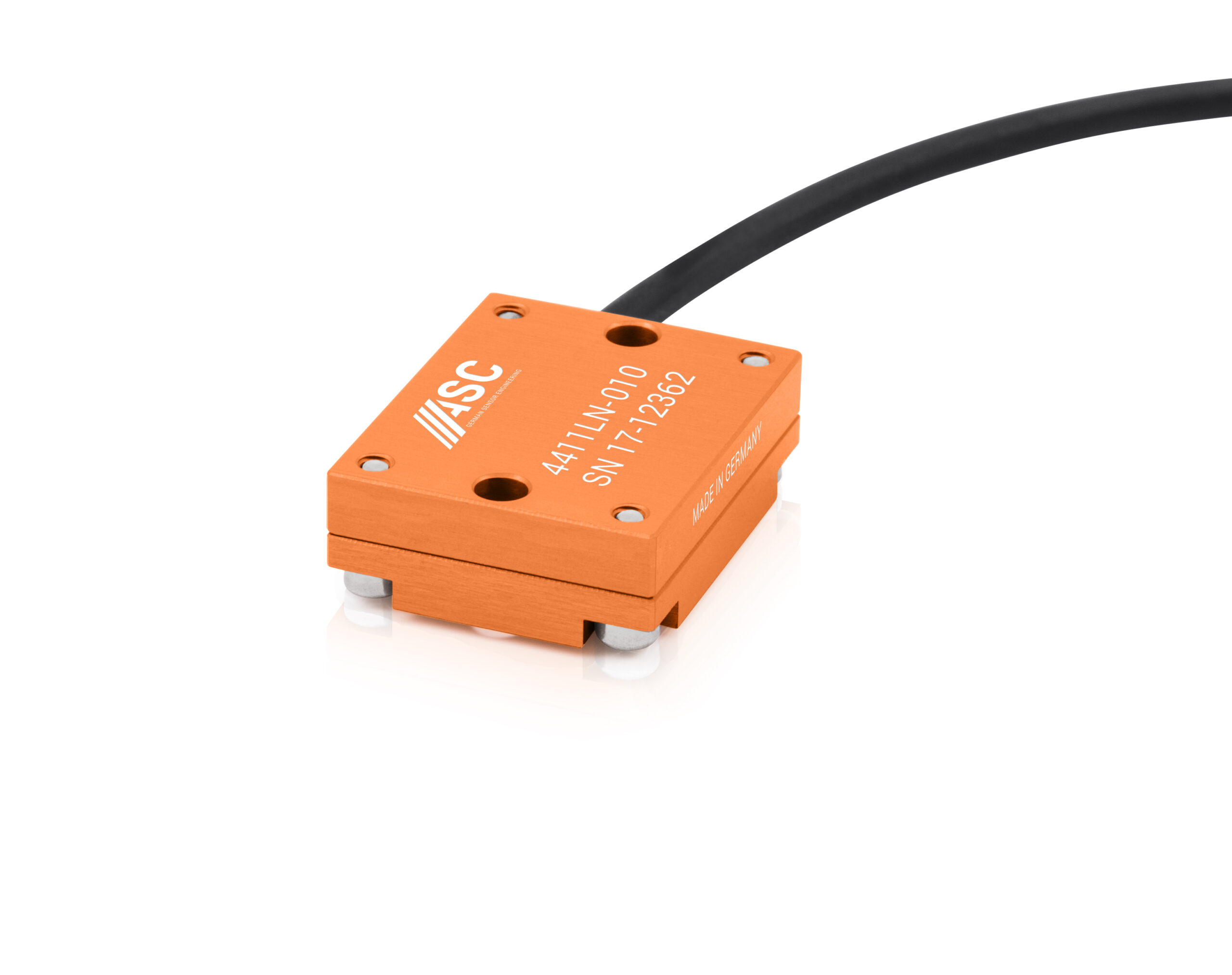

Train Acceleration Sensors

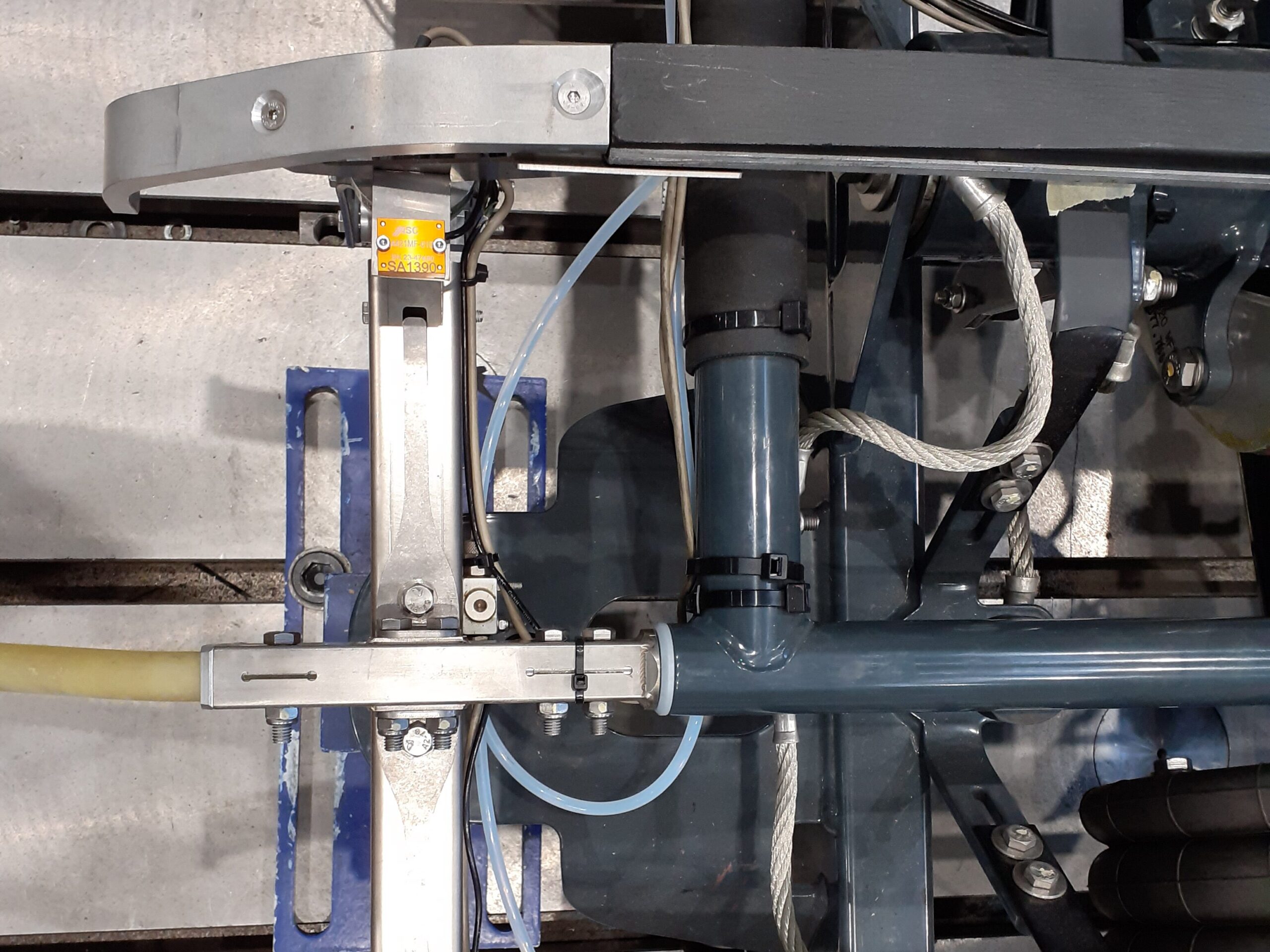

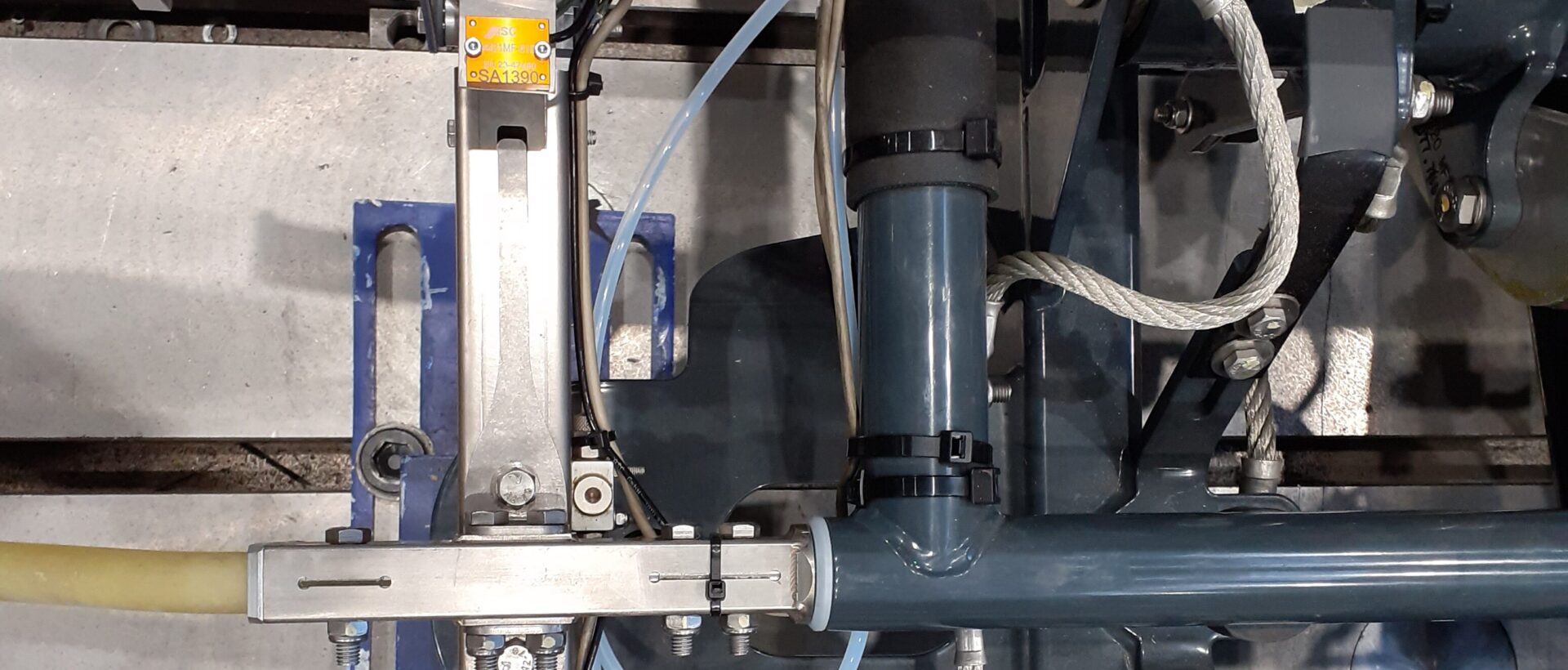

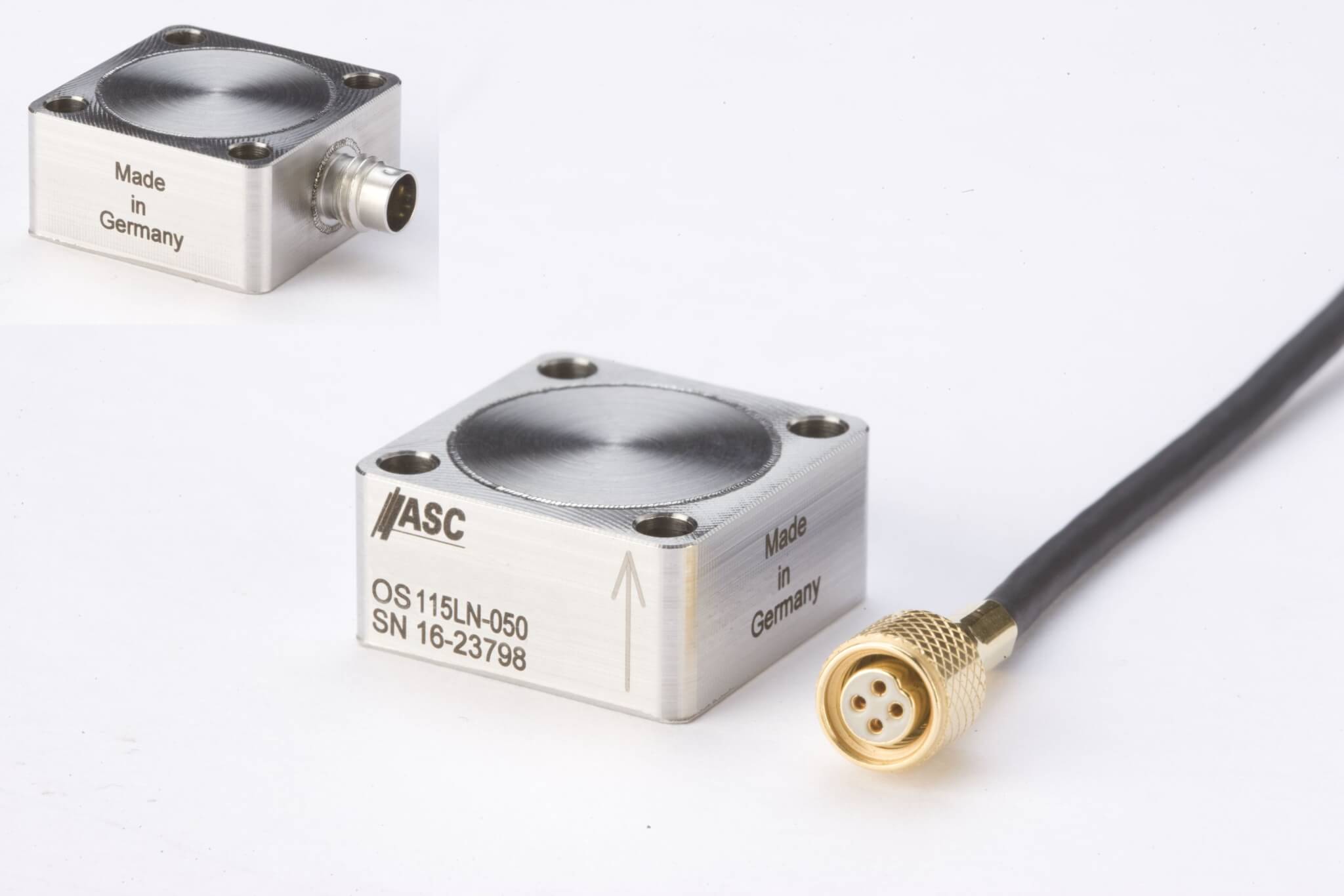

The diverse areas of application often require precisely customised solutions. Therefore, the ASC experts co-operate with their customers to develop completely new sensor solutions or customer-specific adjustments of individual parts such as cables, plugs and modified housings to attach the sensors. ASC implements them in small batches and with short delivery times, which is vital in development departments. ASC products meet a high quality standard that is ensured by keeping production in-house at the Pfaffenhofen site. Furthermore, only high-quality sensor elements of renowned European and American manufacturers are used.

ASC products are characterised by their robustness and shock-resistance.

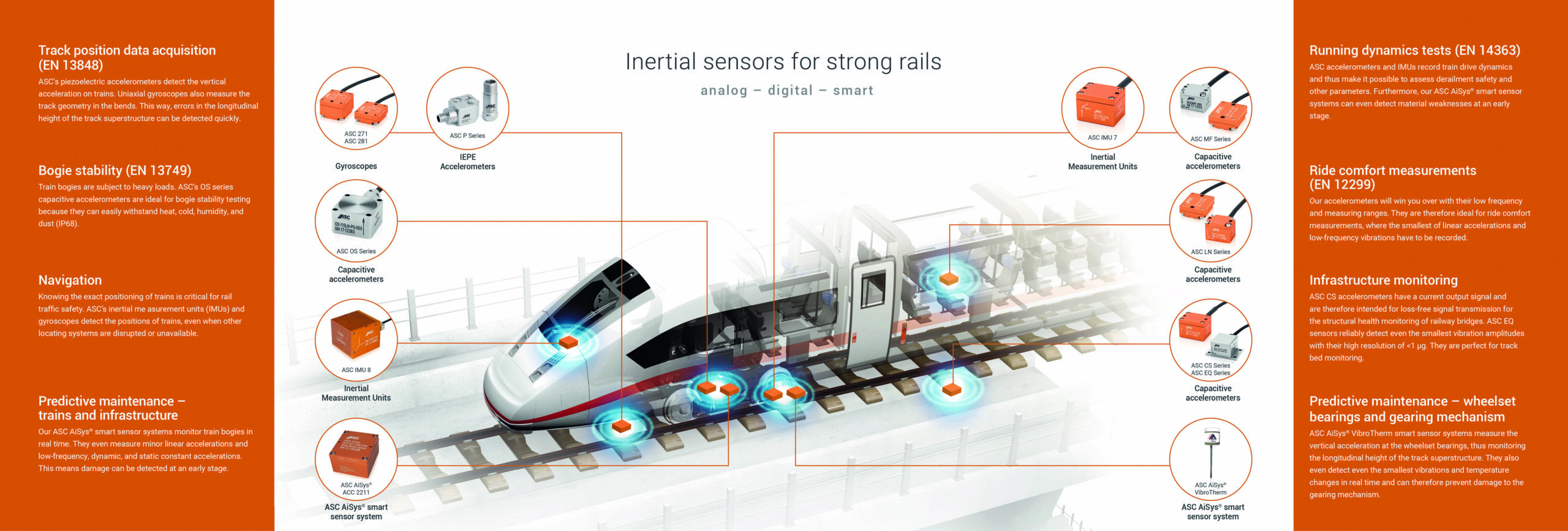

ASC produces train acceleration sensors in three product groups:

- ASC produces capacity acceleration sensors that work with an increased output signal and permit even very small measuring ranges.

- On the other hand, piezoresistive sensors are produced that do not provide signal amplification but a bridge output signal. They are mainly used in crash tests.

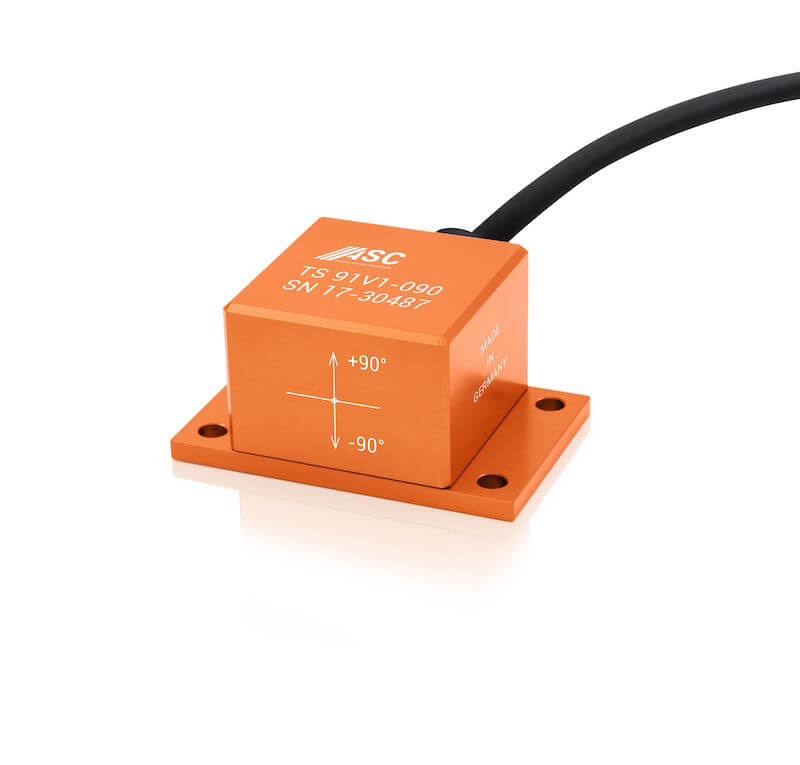

- ASC also produces rotation rate sensors to measure rotating speed, e.g. in the aviation and aerospace, marine, automotive industries and for rail-bound traffic.

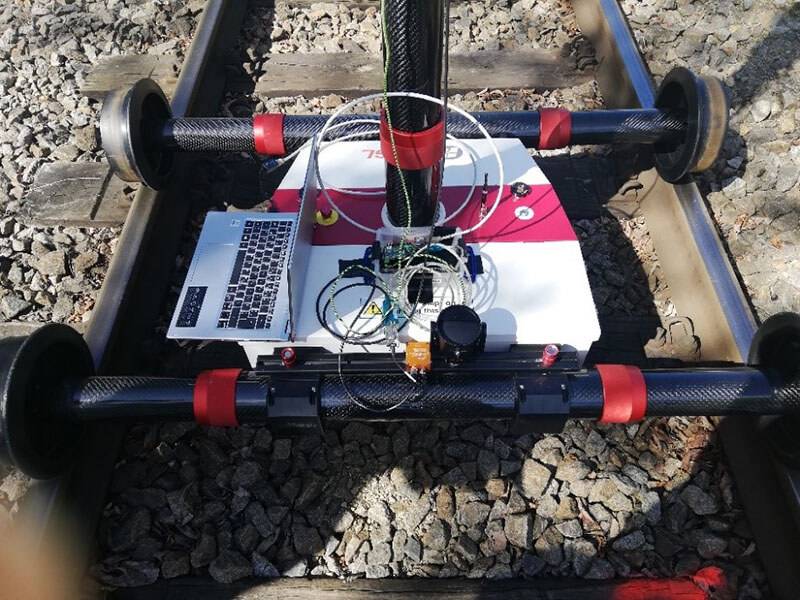

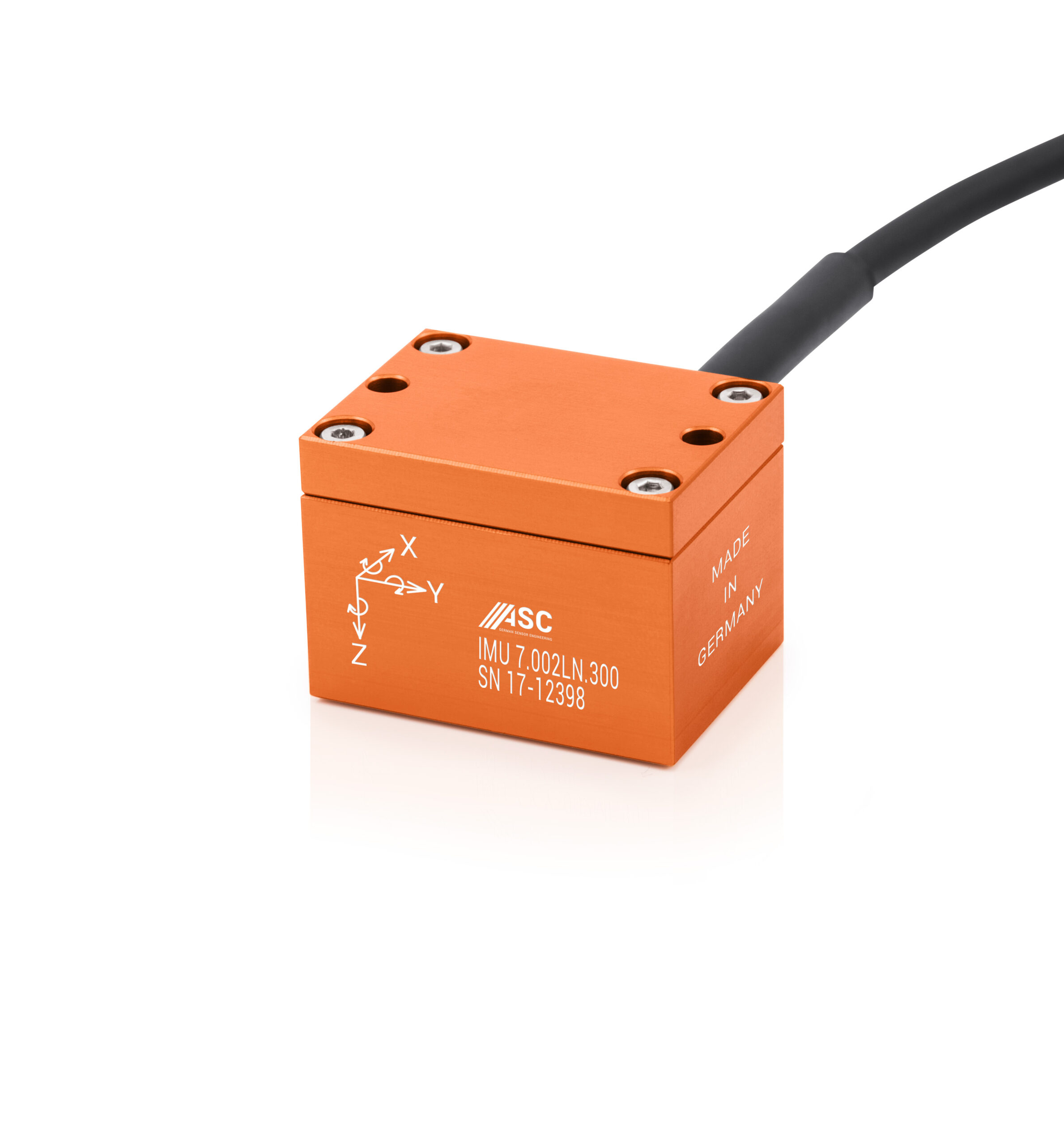

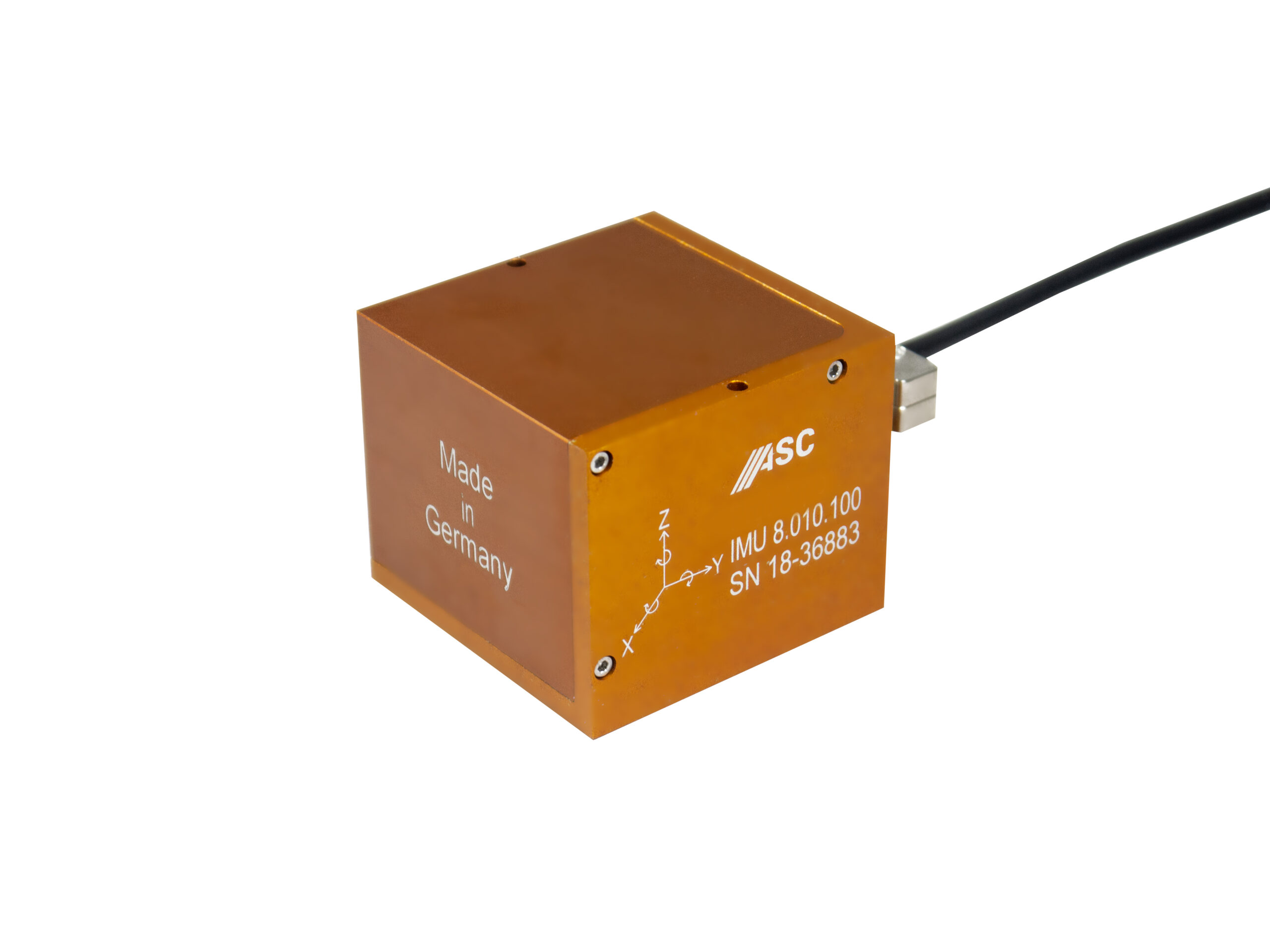

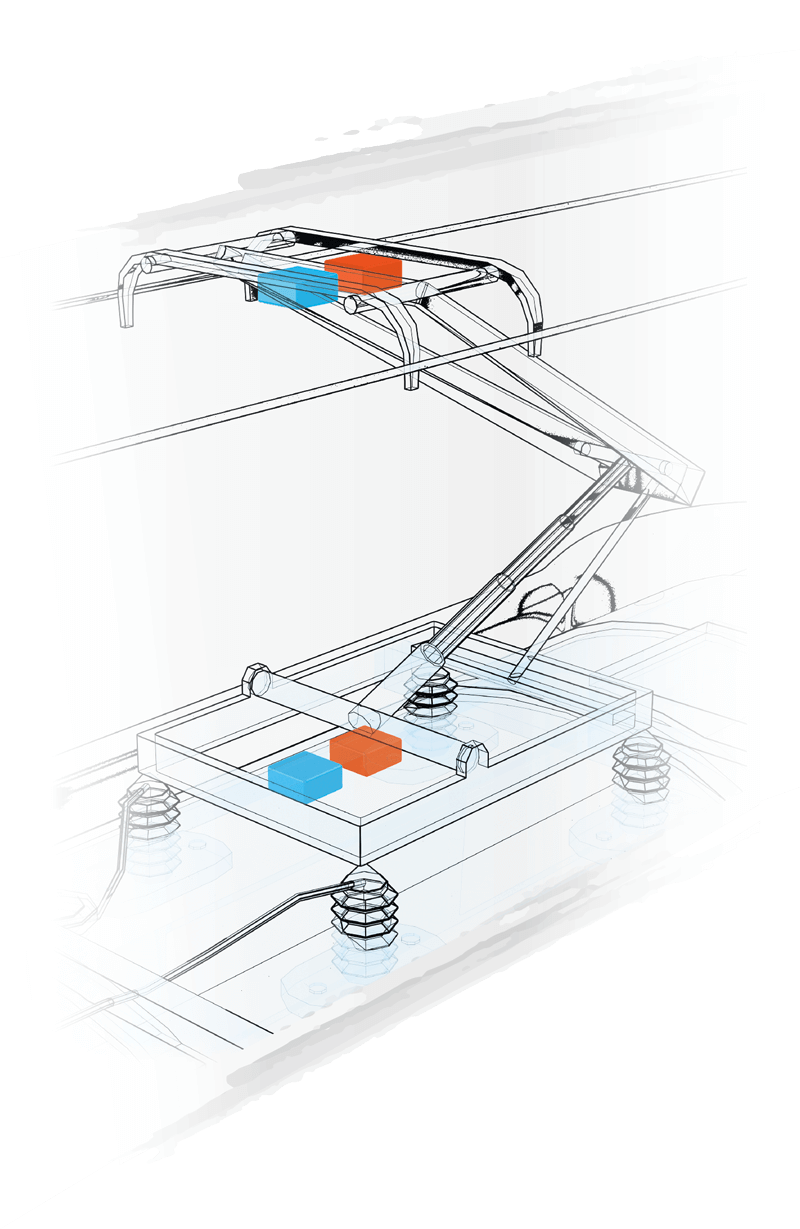

Rail Inertial Measurement Units

Rail Inertial Measurement Units (IMUs) are also part of the product range. These units comprise of three acceleration and three rotation rate sensors each. They measure along a total of six axes. For example, they are used for driving comfort inspection, in rail-bound traffic, in the turbine cockpit and in aviation and aerospace.

Simple and well-structured handling of sensors enabled ASC to develop the sensor identification module ASCTeds. The system comprises of a microchip that can be installed in cables, plugs and housings, as well as of software saved on them. Basic data on the sensor model, sensor sensitivity, offset and the date of the last and next calibrations can be saved in a database.

Train Sensor Maintenance

Comprehensive services for train sensor maintenance complete ASC’s offer: the employees perform maintenance, repairs and calibrations for ASC and third-party products. Thus, the company offers comprehensive customer support that by far exceeds purchase and adjustment of products.

ASC is DIN ISO 9001-certified. ASC has its own calibration lab at its facility in Pfaffenhofen, Germany. The Deutsche Akkreditierungsstelle GmbH (DAkkS) awarded the calibration laboratory of ASC GmbH on 23 April 2013 with the authority to execute calibrations according to DIN EN ISO/IEC 17025:2005 for the following mechanical measurands, Acceleration.

Certificate registration no.: D-K-18110-01-00

In September 2016 the consulting company Frost & Sullivan awarded ASC the “2014 Frost & Sullivan Company of the Year Award”. The points which were especially highlighted were the progressive technology of the products, the high service quality, the continuous extension of the product portfolio, expansion into other markets and the associated proximity to our customers.