Harsco Rail, a global leader in innovative track maintenance and construction solutions, proudly announces the successful completion of a track improvement project in partnership with Trojan Rail earlier this year.

A valued customer approached Harsco Rail to provide a solution for dipped rail welds on their network, impacting their operation through track degradation and potential damage to rolling stock. Harsco Rail provided ‘Rastic’ contracted services, a solution/methodology that has been in practice for close to 20 years. This ambitious endeavor demonstrated exemplary teamwork, precision and commitment to quality by addressing dipped rail faults across 700 kilometres under some of Australia’s most challenging conditions – all while upholding an impeccable safety record.

Collaboration at Its Best

Harsco Rail worked closely with Trojan Rail to deliver this project. On-site labour resources, provided by Trojan Rail, ranged from 6 to 11 crew members at various stages of the project. Every team member played a crucial role in its success, combining expertise and dedication to meet the highest standards. The collaborative spirit extended to the client, whose unwavering support throughout the project underscored the shared commitment to achieving exceptional results.

The Original Rastic Methodology

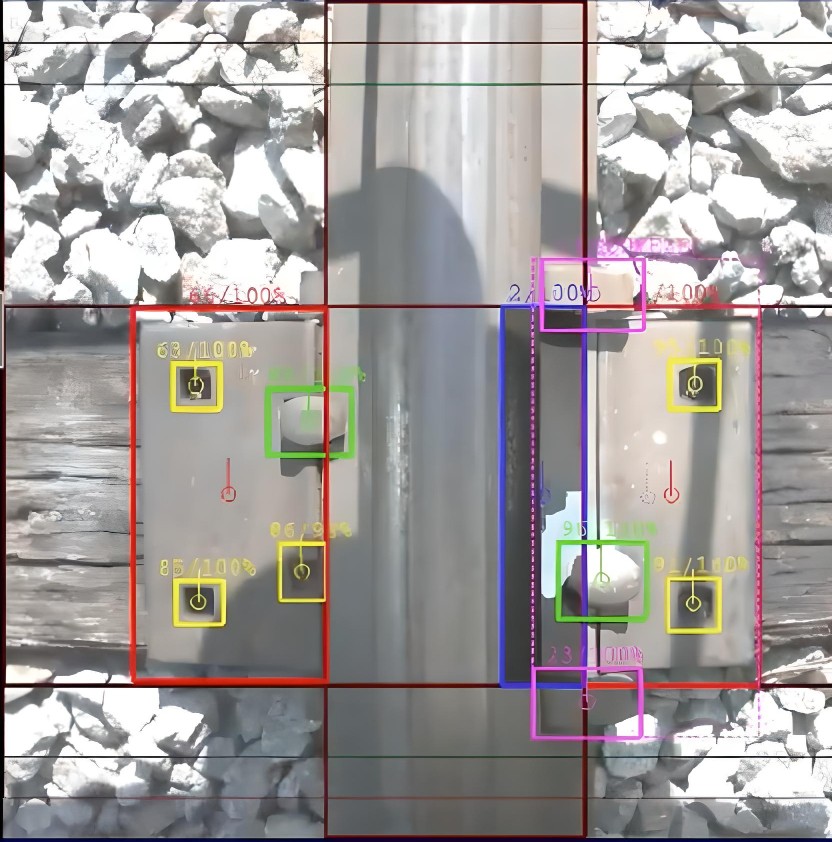

The methodology utilised during this project was robust and innovative, marking another milestone in Harsco Rail’s track improvement capabilities. Key steps included:

- Pre-Measurement: Manual measurements to identify peaks and dips at CWR joints, with markings and notes for variations

- Equipment Utilisation: Deployment of two Rastic trucks and a hy-rail excavator equipped with a tamping head

- Peak Correction: Adjustments using Rastic equipment to achieve 0.3–0.5mm peaks, verified on-site final grinding completed by customer

- Track Consolidation: Excavator tamping three sleepers on either side of corrected dips to stabilise the track

- Rail Breakage Management: Immediate rectification of rare rail breakages (<0.5% of corrections) by skilled rail welders

This methodology has proven effective and reliable, yielding outstanding results and minimal disruptions.

Looking Ahead: The Second Generation Rastic

Building on the success of this project, Harsco Rail is excited to introduce the second-generation Rastic—a concept set to revolutionize track improvement services with cutting-edge innovations. Highlights include:

- Automated Efficiency: Automating track geometry measurements, including peak and dip detection, for enhanced productivity and accuracy

- Improved Safety: Enhanced people/plant separation and upgraded designs for lower centres of gravity (COG) and vehicle stability

- Expanded Coverage: Ability to bend 68kg rails, covering Australia’s standard gauge network comprehensively

- Upgraded Systems: Advanced bending algorithms, touchscreen controls and better diagnostics to reduce downtime and boost productivity

- Crew Optimisation: Reduced on-site crew sizes due to automation, lowering operational costs

- Regulatory Compliance: RISSB-compliant upgrades hy-rail vehicles

- Smart Reporting: Automated production reports for seamless progress tracking

The second-generation Rastic redefines track maintenance by offering customers a cost-effective, safer, and more efficient solution for their network’s dipped rail corrections.

Our Commitment to Excellence

The accomplishments of the Harsco Rail team, Trojan Rail and our dedicated client highlight the power of collaboration and innovation. As we move forward, Harsco Rail remains steadfast in its commitment to quality, safety and continuous improvement – ensuring every project meets and exceeds expectations.

This article first appeared in the Railway-News Magazine Issue 1 2025. Download the full PDF version here.