Assembly of an ESL M12 X 1,75 in Classe 8 with a Zinc Lanthane® Protection 175 + Filmogene

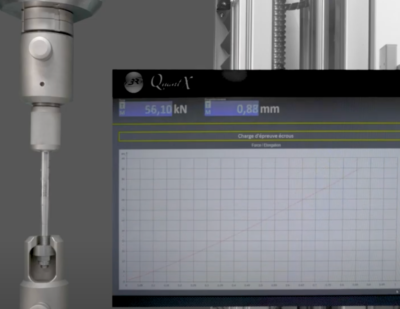

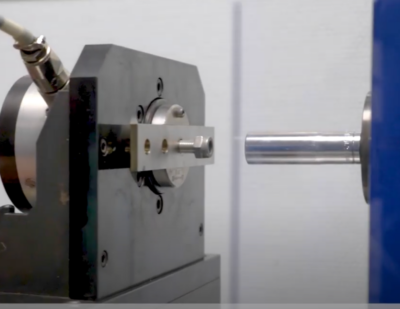

The process for assembling an ESL nut.

- Do not use additional lubricant

- Use the same quality class for the nut and screw

- Do not use impact wrenches

- Use a long sleeve for a better opening of the slots

- Screw at slow speed (less than or equal to 30 revolutions/minute) to engage slots

- Screw until a minimum of two threads of the screw come out of the turret and the nut

- Check out that the slots are open correctly

- Finish tightening at 500 rpm/minute or less

- The torque tightening is calculated according to the standard NF E 25-030 defined by the Engineering Office responsible for the assembly