Condition Based Maintenance in the Rail Industry

Condition based monitoring has been in the rail industry for some time, but we are now moving to the next generation – Condition Based Maintenance. Dr David McGorman, Managing Director of Unipart Technologies Group discusses where we are now – and what the future holds.

I’ve been interested in the transformative power of data for my entire career, and the effect that it can have on decision making. To coin a phrase from the British mathematician Clive Humby, Data is the new Oil!

Experience can be relied upon to guide decision making – after all, it’s only through understanding the past that we can avoid making the same mistakes, but experience only goes so far, especially when we’re talking about highly technical and complex technology. If you start to use that historical knowledge to make judgments about things, such as calculating an MTBF on a product based on what goes before, then you get exactly that – the ‘mean time’ not an asset-specific understanding of condition. And that approach has been the basis of maintenance based on periodicity or reactive maintenance.

But we all know that means that a fair proportion of the time you’re maintaining an asset that could continue in service for months – or years – without the need for intervention. And you could also be faced with an asset with a catastrophic failure BEFORE the MTBF or planned maintenance interval, leading to delays, damage and even fatalities, particularly in the rail sector. The stakes are that high.

With the aim of rail asset owners, operators and maintainers to be able to extract the best performance from the asset with the highest levels of safety and cost optimisation, those owners are now looking beyond the data for solutions.

Data Science

In recent times condition based monitoring has been used to monitor an increasing number of assets both trackside and train-borne, and make decisions based on that data. So what’s the difference with condition based maintenance?

The difference lies in the value that you can extract from the data. Monitoring technology delivers huge amounts of data that can be used to inform maintenance programs, but if you are only looking at the asset and responding to the narrow data, then you may be missing an opportunity.

Data Science is where the opportunity is grasped. Deep understanding of what the data really means is the next step. Combining multiple data sets – including from the asset, but also from the environment in which the asset operates – is essential to be able to plan your maintenance efficiently and proactively.

We’ve been doing this in the F1 sector for years. Instrumentel – a Unipart company – places sensors right in the heart of the F1 engines. Withstanding huge pressures and temperatures, the sensors provide data to the Team, and the Data Science exposes the areas with pinpoint precision where in-race adjustments can be made to get that micro-second advantage. Where this is applied very effectively is before a car even takes to the track, or the engine is inserted into the car, where engines could be improved outside the race to extract every possible advantage.

Now, whilst the imperatives of F1 and the rail industry are very different, the use of data is the same. Deliver cost, safety and performance improvements whilst reducing risk.

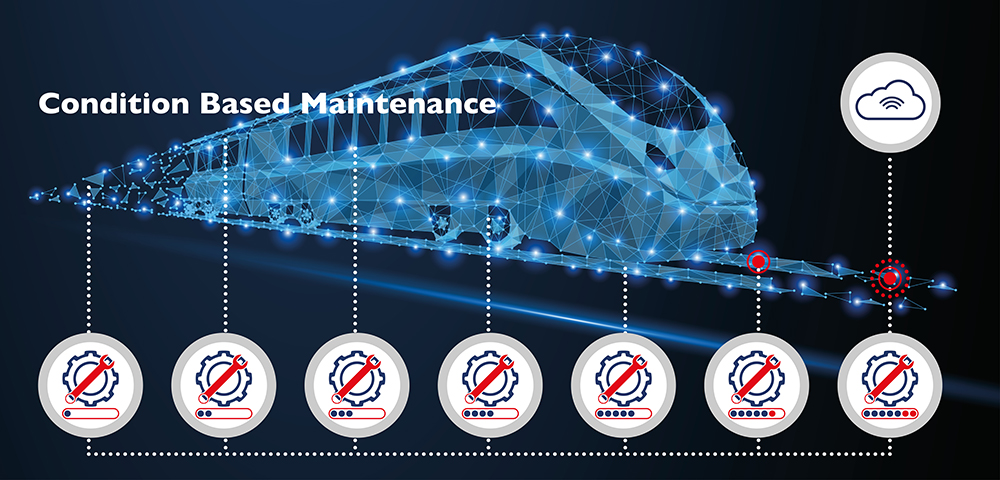

Condition Based Maintenance

Picture this – a sensor on an asset tells you it’s not performing properly. So you schedule testing of the asset, maybe have it taken out of service and sent for a review with the OEM and they find nothing. I’m sure this is a familiar picture for many readers, this can be because the asset is not stand alone; it is part of a system, and your monitoring isn’t aligned with maintenance requirements.

Now picture the same scenario, but where the data from the asset is mapped with data from other assets and from the environment. Suddenly the real cause is obvious – a power drop because another asset has just turned on, or a rise in pressure creating an increased exhaust temperature, or an environmental temperature rise that has impeded the function of the asset. Now your maintenance response would be very different.

We’re now building the elements of the system that will deliver Condition Based Maintenance – and the Condition Based Supply Chain – that will integrate data with automated interventions. Better data science that will deliver more actionable data, and systems that will help asset owners to automate asset maintenance.

This is not in the future – it’s now. With customers like Porterbrook where we are now fitting engine and fuel systems sensors on their fleets, in a programme that starts now with South West Trains and Cross Country fleets. I recently met with Stephanie Klecha – Porterbrook’s Head of Digital Services – who said “Instrumentel’s business directive and our business directive is all about utilising digital technology to drive change in rail – having a partner who understands that collaborating with us in that journey is critical in its success.” You can watch the film here.

The parallels with F1 in this area are clear. We are going to provide that insight into engine performance and fuel usage that will enable the TOCs and Porterbrook to manage their fleets more effectively and drive performance and cost improvements, whilst reducing the risk of system failure.

Scale from Data

With multiple fleets now being fitted with sensors, we get the benefits of having data from multiple units to compare – and also to be able to deploy maintenance learning across multiple assets to maximum effect. As these data sets increase, the insights that are gleaned from them will become more insightful and increase maintenance savings further.

As we will be dealing with assets before the failure causes any problems, the major asset (vehicle or track section) will have lower down-time, meaning that the asset is more available for active service, positively impacting delay minutes and customer satisfaction – both areas of huge concern for the rail sector, and extracting maximum benefit from the national fleet.

This article was originally published by Unipart Rail.