The East Japan Railway Company have awarded a contract to PARC to supply its hybrid Condition-Based Maintenance (CBM) technology. PARC will enable East Japan Railway to phase out schedule-based maintenance operations and replace them with a system combining modelling and data analytics. The pilot of the system includes the utilisation of the technologies for train doors and track condition image analytics.

PARC Condition Based Maintenance systems have already demonstrated their worth for East Japan Railway on their rail switch machines. East Japan Railway has benefitted from high fault detection accuracies from PARC algorithms, in certain instances exceeding 90%, with negligible false positive rates

The deployment of connected sensors, combined with advances in data analytics, allow maintenance operations to be carried out based on the actual condition of assets, rather than a usual schedule-based maintenance system. This pilot will allow PARC’s CBM technology to undergo extensive field testing by maintenance teams.

Atsushi Yokoyama, Director General, R&D Center of the JR-East Group, said:

“Our growth has decreased due to population decrease, so we want to reduce spending on maintenance activities to help improve the bottom line. We examined multiple organisation to help us determine an innovative and futuristic approach to maintenance, and decided to evaluate PARC’s CBM approach. We have been pleased with the pilot results. We are now in discussions around operationalising the developed CBM solutions with PARC and productising partner Nomura Research Institute (NRI) for train doors and rail maintenance operations. We look forward to continuing our relationship with PARC and NRI to enable CBM for other train systems of interest.”

Anurag Ganguli, PARC Senior Research Scientist and Project Lead for the JR-E CBM engagement, said:

“These problems of labor intensive and schedule-driven maintenance are not unique to Japan or even train systems, and is a pain point across many countries and varying types of infrastructure systems. Even within an industry vertical, such as railways, each piece of equipment or asset is unique. Developing technologies that can scale to address each challenge while simultaneously achieving high true positive and low false positive rates is essential. PARC’s multi-disciplinary team is developing a core set of CBM technologies based on model-based reasoning and machine learning that can do just that.”

PARC Condition Based Maintenance Technology

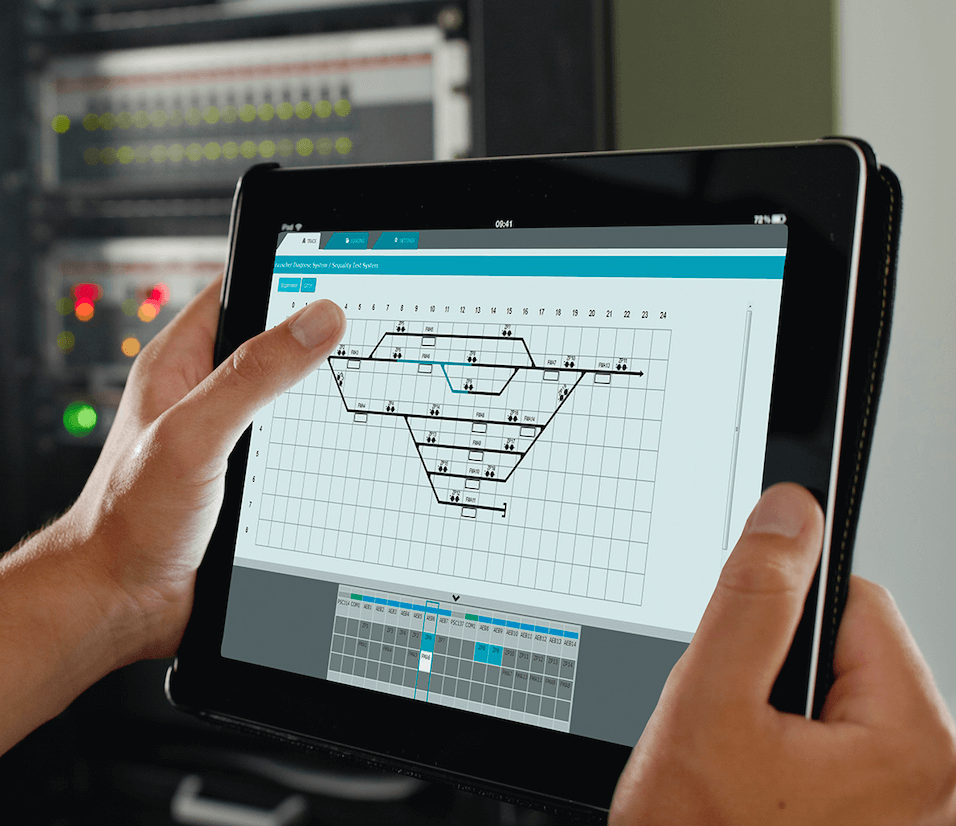

PARC Condition Based Maintenance Technology puts low-cost, embeddable sensors into systems in a non-invasive method and there they can directly monitor they system. The sensor data then is put into system models which automatically augment with a range of anticipatable faults. PARC can then develop a comprehensive view of how the system works or doesn’t work and rapidly delivers an informed failure sensitive algorithm to pick up abnormal system operations.

PARC’s model-based diagnostic system supplies a very accurate classification of system faults and identifies vulnerable sub-systems which can lead to system failures. PARC CBM components also allow for prognostics algorithms which predict failure points in a variety of scenarios. This can all be combined to created a concise recommendation with actionable suggestions for optimal response options.