Rail Welding Technology

Leading in stationary and mobile rail welding technology for more than 100 Years

Schlatter is a market leader in stationary rail welding machines for long welded rail production (LWR) and for welding machines for turnout parts, frog points and crossings. The mobile rail welding systems are well known worldwide and widely used for welding continuous welded rails for high speed tracks and heavy haul tracks.

Rail Welding Machines

Focus on customer benefits with flash butt welding systems

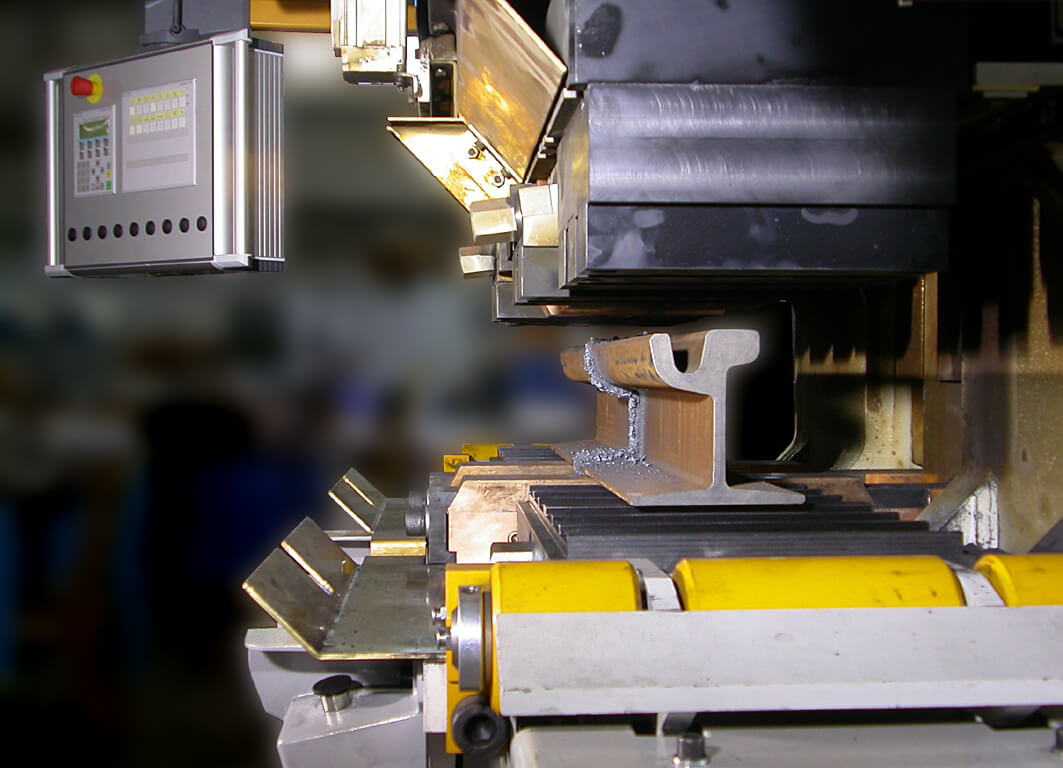

In Schlatter rail welding machines the focus is on quality. This comprises both: Quality, long life time and low operation costs of the machines but also quality of the final rail welds. For good quality welds, Schlatter developed the designated Schlatter Weld Processor (SWEP) which controls the main parameters ‘current’, ‘force’ and ‘travel’ and their correctly timed interaction. These three parameters are constantly supervised by the new Schlatter Weld Analyzer which records every weld. Setting tolerance fields allows deciding if the parameters are in the desired range immediately after the welding process.

Mobile Rail Welding Machines and Systems

Schlatter offers various mobile rail welding machines and systems for in-track welding of continuous welded rails (CWR). The latest development produces closure welded tracks without separate pulling devices for distressing. Customers can choose between three different mobile rail welding machines: AMS200, AMS100 and AMS60. All these mobile welders offer the same high welding quality but different rail end aligning systems. AMS200 and AMS60 aligns on the running edge, left or right side selectable, and is most suitable for high speed railway tracks for passenger transportation. Furthermore the AMS200 has an autarkical deburring system, which allows to deburr the whole rail profile automatically directly after welding, even both rail end are in clamped position. The AMS100 aligns the centre of the web and is mainly designed for heavy haul and conventional railway tracks. Our AMS100 and AMS60 rail welding machines also have an incorporated deburring system which deburrs automatically, directly after welding around the complete rail profile.

Truck or Container Based Rail Welding Systems

Two alternative rail welding systems are available: Supra Roadflex, the truck based system for road / rail operation with very high flexibility. Supra Multiflex, consisting of standardized containers which can be mounted onto flat wagons or can be used semi-stationary at the job site.

Stationary Rail Welding Machines and Systems

Welding short rails into long welded rails

The renowned Schlatter rail welding machine GAAS80 is worldwide in daily welding operation in rail welding factories. It features DC weld current, precise alignment of the rail ends (on running edge, selectable left or right side), precise vertical alignment including ‘crown-position’, outstanding weld quality and automatic deburring only seconds after welding. The rail ends remain clamped during deburring which contributes to quality. Little remaining burr around the rail profile results in easy and cost effective grinding.

For complete production lines, Schlatter cooperates with experienced partners for the additional machines like rail end brushing machines, straightening presses and rail profile grinding machines.

Flash Butt Welding Systems

Railway switches and crossings welded with Stationary flash butt welding systems

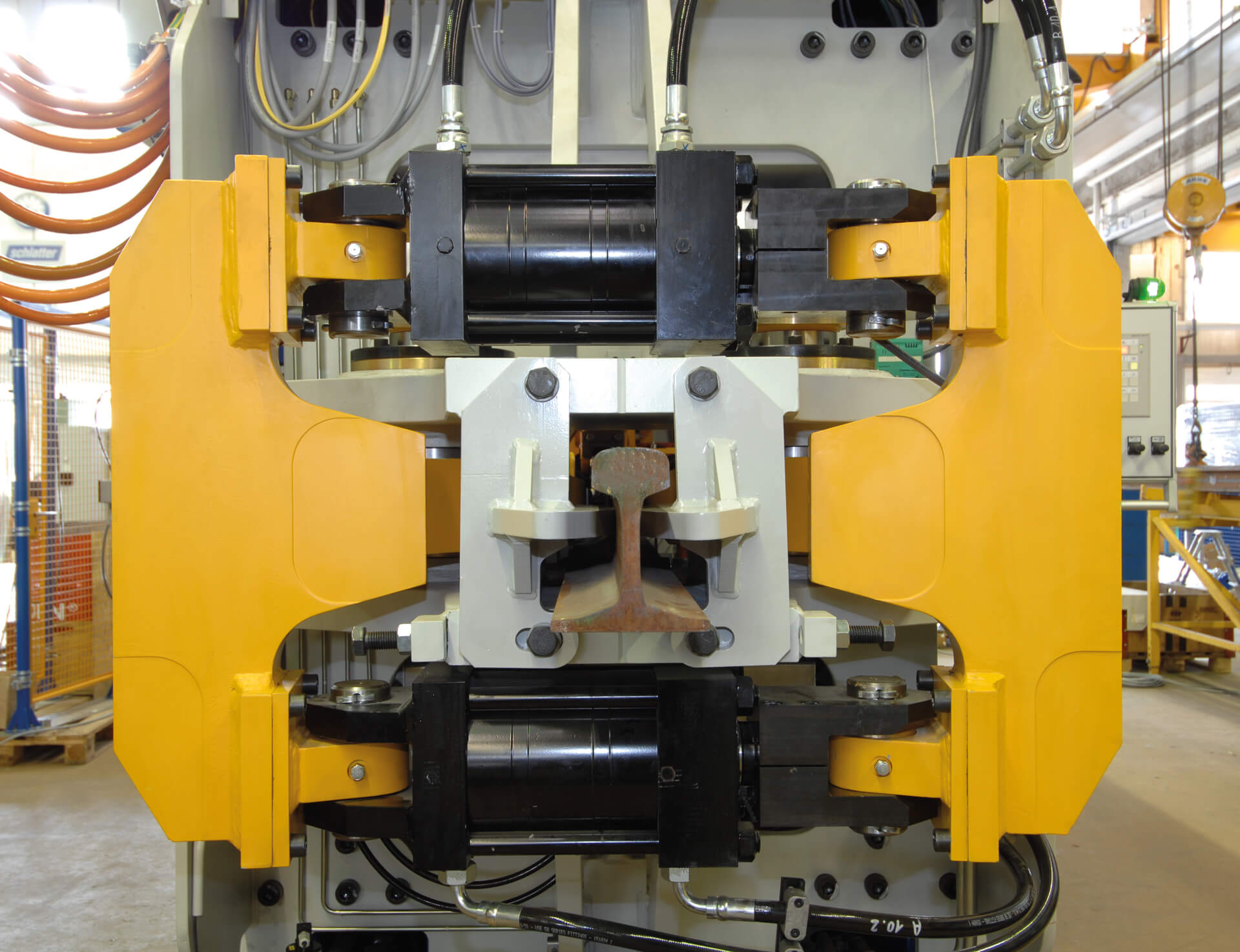

The Schlatter GAA100 flash butt welding machine has an extremely compact housing, open at the front for easy loading and positioning of work pieces. There are four clamping presses in total, each with 1000kN clamping force, ensuring that there is no slip.

Railway turnout parts, points and crossings as well as switch blades are exposed to very high loads. For a long service life, manufacturers use hard manganese and high alloy steel which is welded to conventional rail steel with the Schlatter GAA100. This requires complex weld programs and special processes.

Major manufacturers of turnouts and switch blades use the Schlatter GAA100 successfully for its flexibility, its high quality welds and for its geometrical accuracy.