LPS

Autumn-Proof Your Railways: Introducing LPS LaserTrain

This article first appeared in the Railway-News Magazine Issue 3 2023.

Advanced Technology to Ensure Smooth and Reliable Train Services

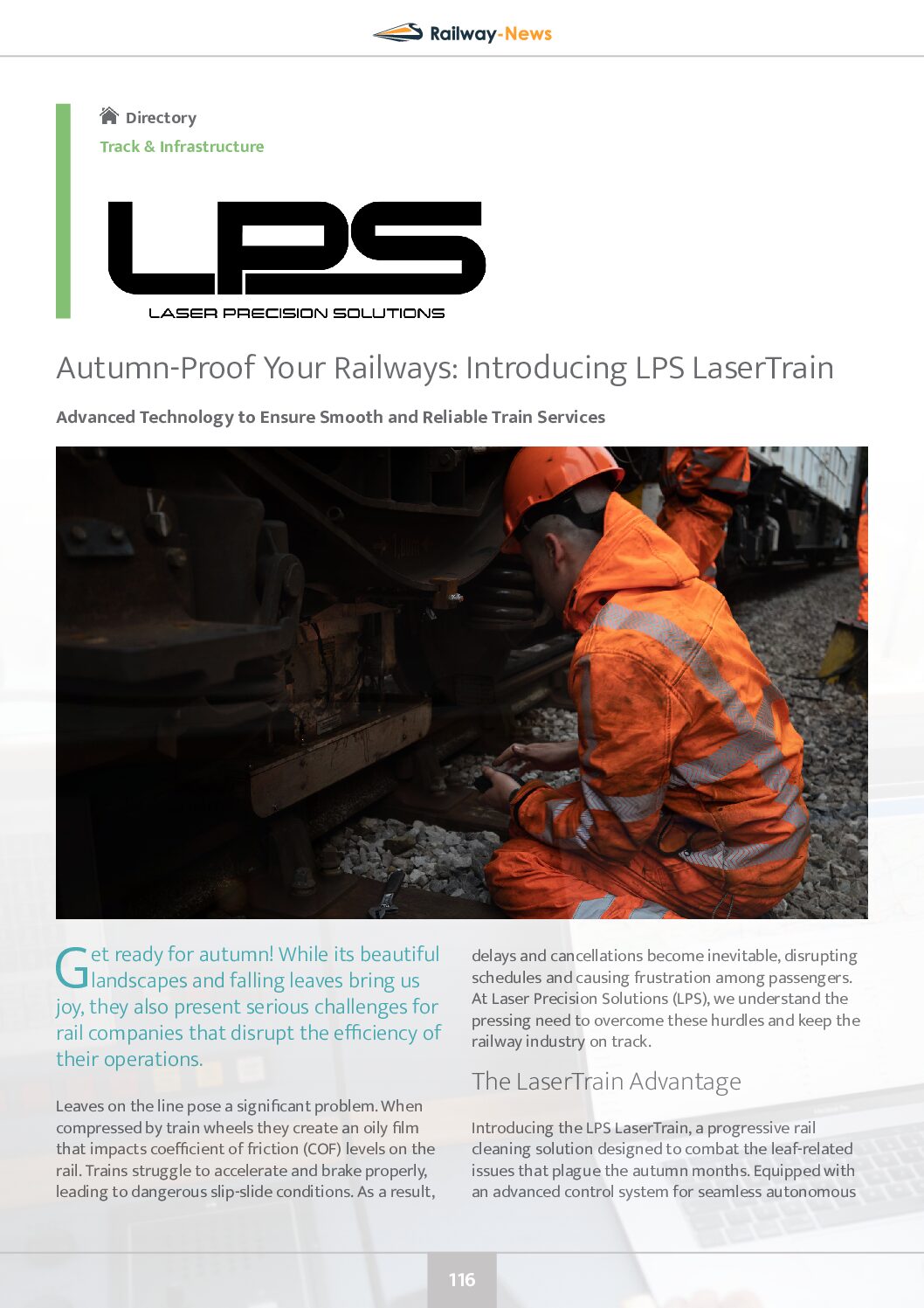

Get ready for autumn! While its beautiful landscapes and falling leaves bring us joy, they also present serious challenges for rail companies that disrupt the efficiency of their operations.

Leaves on the line pose a significant problem. When compressed by train wheels they create an oily film that impacts coefficient of friction (COF) levels on the rail. Trains struggle to accelerate and brake properly, leading to dangerous slip-slide conditions. As a result, delays and cancellations become inevitable, disrupting schedules and causing frustration among passengers. At Laser Precision Solutions (LPS), we understand the pressing need to overcome these hurdles and keep the railway industry on track.

The LaserTrain Advantage

Introducing the LPS LaserTrain, a progressive rail cleaning solution designed to combat the leaf-related issues that plague the autumn months. Equipped with an advanced control system for seamless autonomous operation and high-intensity lasers, the LaserTrain offers precise cleaning without damaging tracks. One pass improves slip-slide conditions for 24 hours for safer and more efficient operations. By doing so, disruptions are minimised, and overall passenger satisfaction is improved.

Safety First

Safety is paramount to any rail operation. LaserTrain features such as automatic laser shut-off at speeds below 2mph prevents excessive exposure and unnecessary treatment, ensuring precise and controlled cleaning operations. The control system seamlessly transitions between ‘Transport Mode’ and ‘Cleaning Mode’ avoiding rail obstacles without operator intervention. Transport Mode raises the Laser Technology to avoid rail obstacles, while Cleaning Mode lowers it for track cleaning.

Optimised COF levels guarantee safe braking and accelerations with no speed restrictions, detection of trains and SPAD. Variable cleaning speeds are also available to accommodate the diverse requirements of rail networks.