IMA Dresden – the Test Center for the Railway Industry

Rail Material and Component Testing

IMA Dresden is the independent, accredited and certified test center for the railway industry. With internationally recognized testing services, we support the development departments of manufacturers and suppliers throughout the entire development of a product.

As such, we offer solutions that provide developers and engineers with reliable support in ensuring product and operational safety and quality assurance. As such, we bring together engineers and technicians from several fields of expertise – measurement and control engineering, computing, construction, test design and assessment. We aim to provide testing and engineering solutions that help customers to test forward-looking products thoroughly and validate them quickly, while complying with strict legal requirements.

This means that we test and validate bogies, railcar bodies and many other rail vehicle components, including electrical components, in our test halls on 10,000 square meters of test area. If required, we also uncover structural damage using non-destructive testing techniques, and analyze damage and material properties.

In addition, we conduct measurement runs, assess measured data and use these to define test programs all over the world. We calculate and create virtual simulations of loads, assess the strength of products and areas of stress, and carry out strength and lifespan assessments.

You can rely on us: our laboratories are certified according to DIN EN 9100, accredited according to ISO 17025.

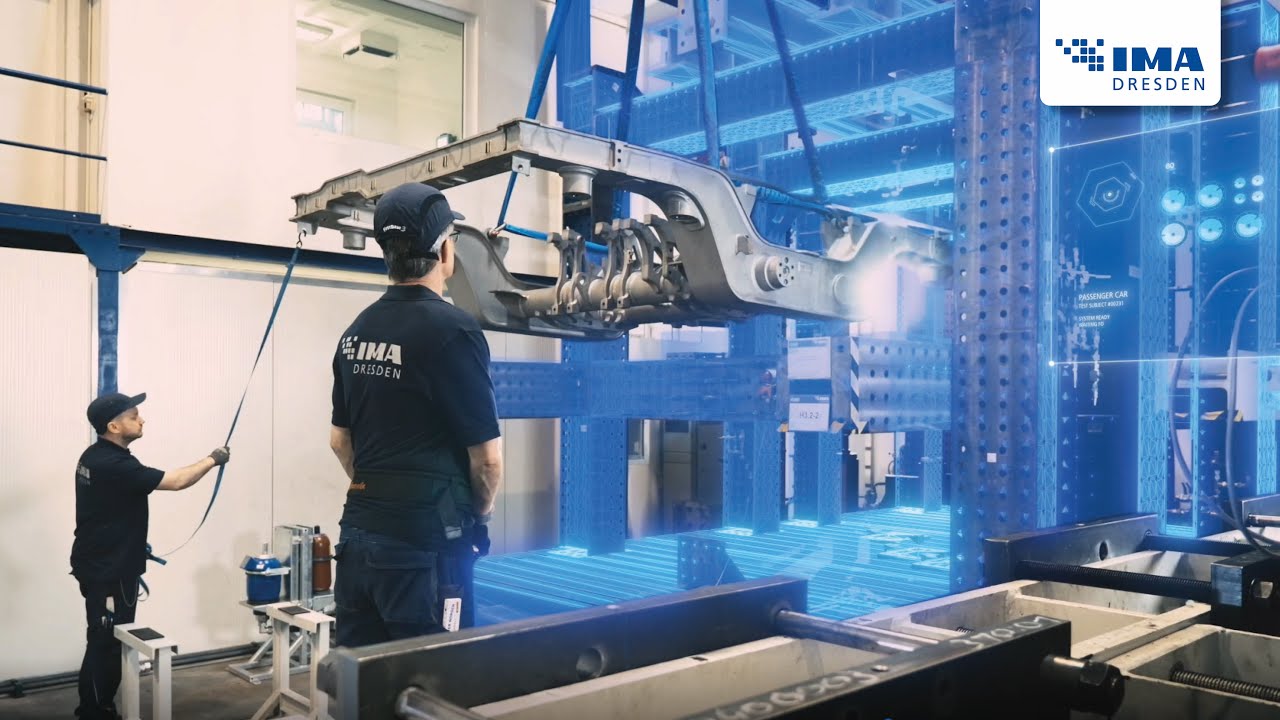

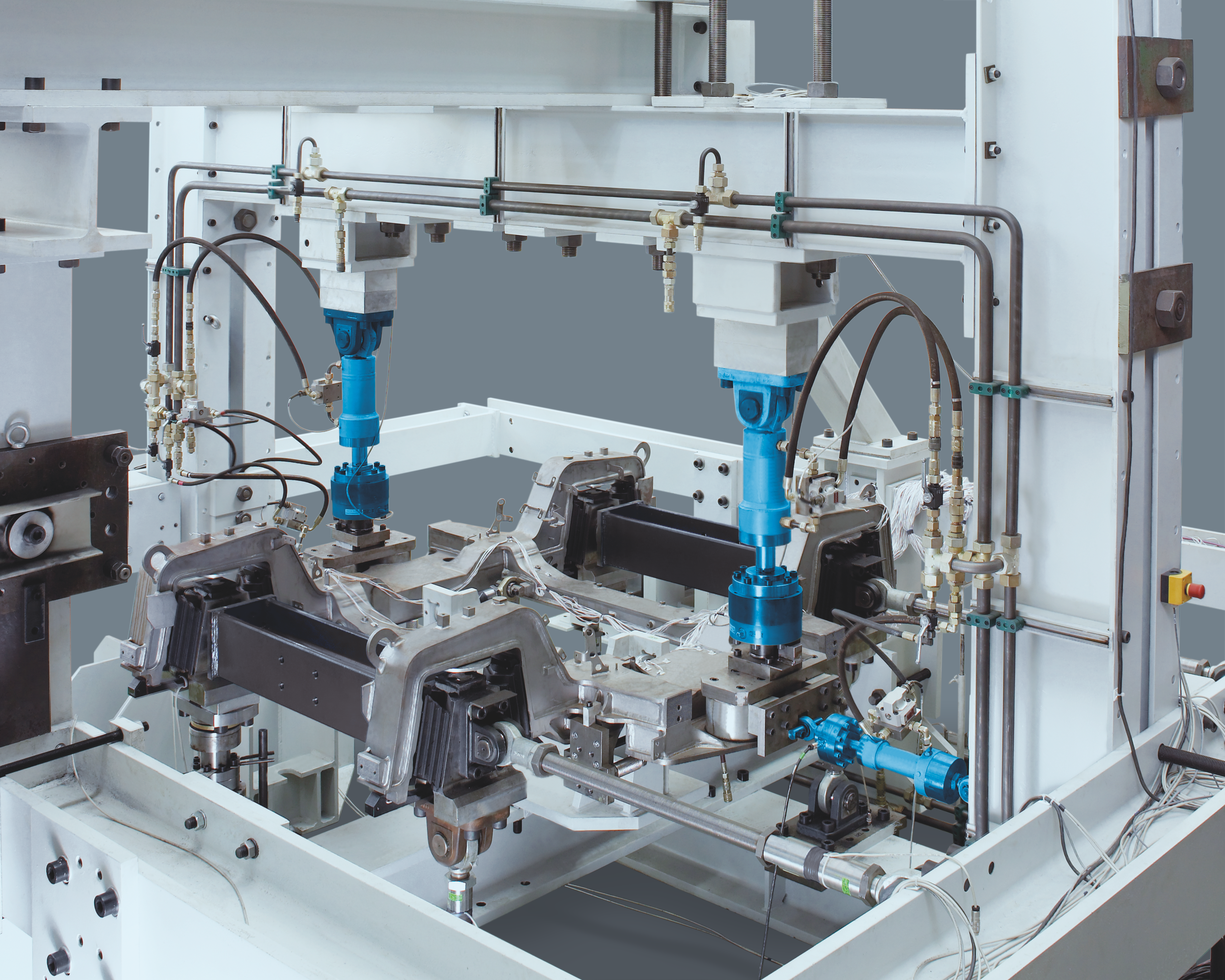

Bogie Frame Tests and Fatigue Testing of Rail Vehicles

Whether you need carrying or motor bogies for locomotives, freight or passenger trains, we offer complete execution of strength testing, including transport and structural analysis, for the approval and development of bogies and bogie frames.

We are an accredited and certified testing centre for approval testing in line with DIN EN 13749 (wheel sets and bogie determination procedures for bogie frame stability requirements) and the UIC regulations for the approval and examination of vehicles in accordance with Section 32 of the Ordinance on the Construction and Operation of Railways (Eisenbahn-Bau- und Betriebsordnung, EBO).

Rail Car Body Tests

Whether we’re looking at double-decker cars, tram cars or middle carriages, our experience in strength testing is uniquely extensive, exactly like our testing capacity in our 4,000 square meters test area especially for rail applications.

With three separate test tracks we carry out static and dynamic tests on the car bodies, also with temperature load. Your own load requirements can also be taken into consideration.

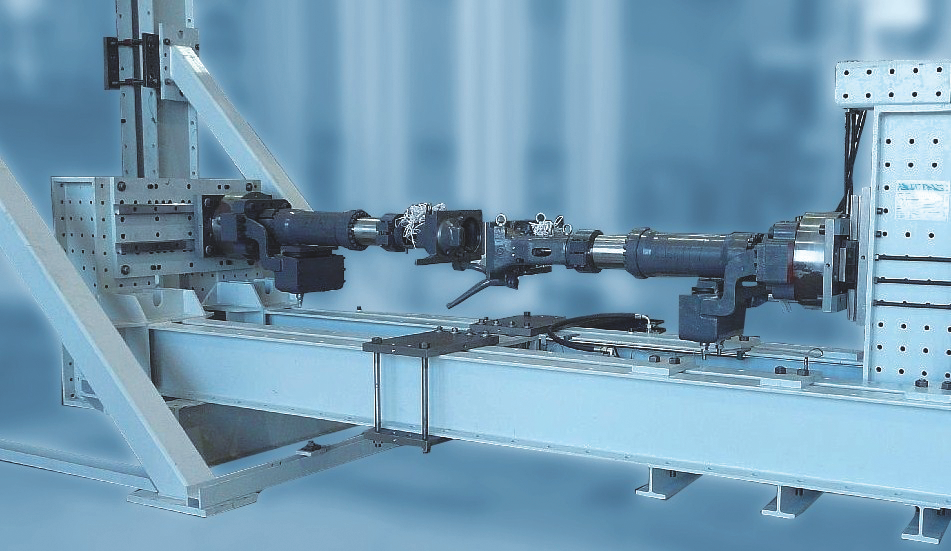

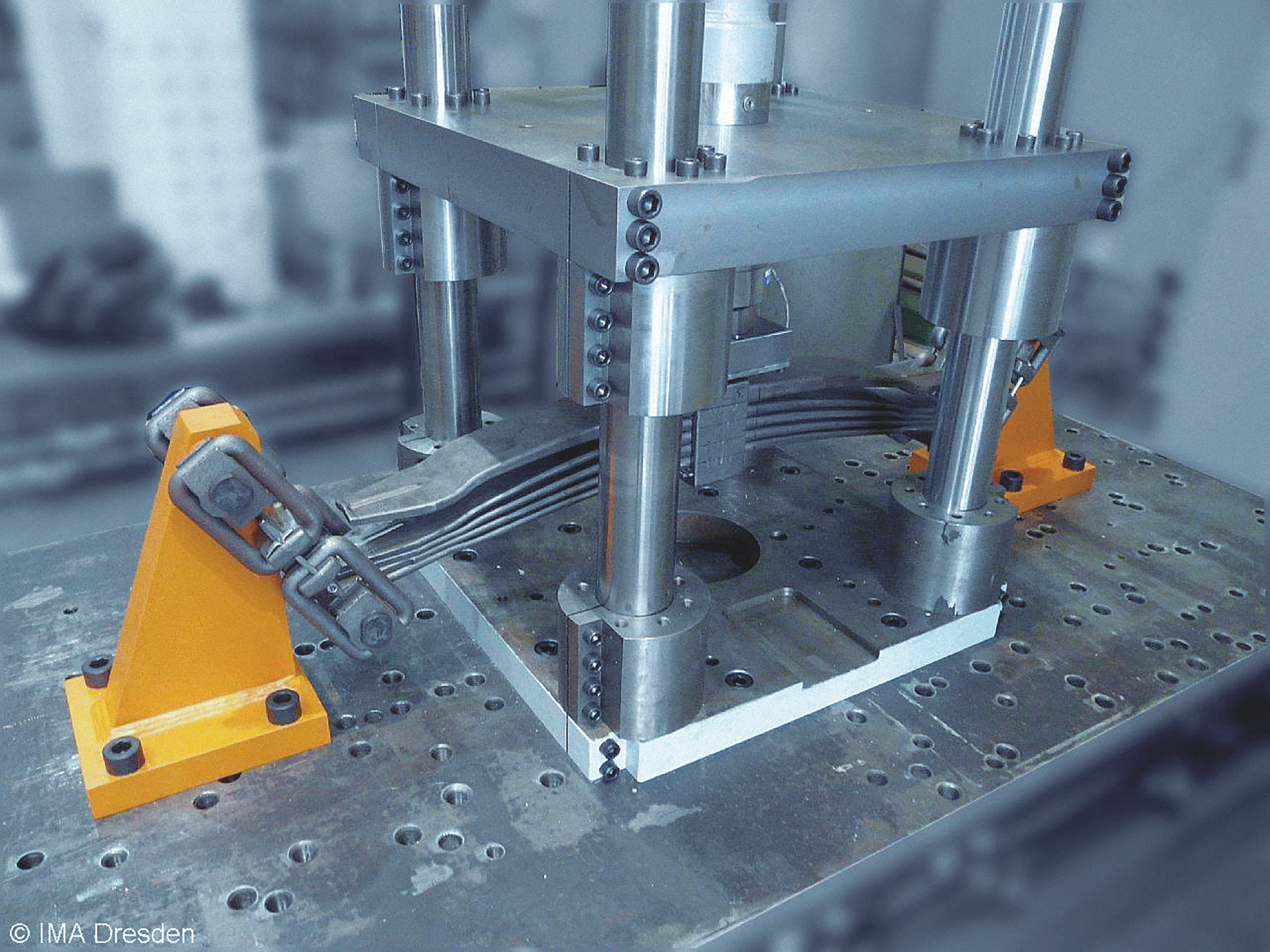

Rail Component Testing

From spring and coupling via wheel set bearing through to axle bearing housing test. We carry out strength tests on all rail vehicle components.

With the greatest care, we examine every desired detail and offer optimized test scenarios to ensure the safety of the components.

We not only implement computational and theoretical but also experimental simulations for static and dynamic loads on your components, develop test concepts and individual testing devices and elements for load introduction.

Material Testing for Metals, Plastics and Composites

We will assume the comprehensive determination for your material parameters as well as evaluating the loading capacity of metallic materials, jointed connections or hybrid material combinations.

Depending on the requirement, these tests can be executed at lower and higher temperatures as well as under media influence. We determine the lifetimes and characters of adhesives, welded and other mechanical joint connections. We analyze the inter fiber breakage behavior of FRP and we test friction and strength for static and cyclical demands. Finally, we offer you acceptance and approval tests for materials and monitor your manufacture.

On Track Measurement – Stress Measurements and Test Drives

Utilizing appropriate measurements, measuring runs and continuous monitoring enables us to record loads in actual applications – whether for approval trials and tests, calculation and simulation or for structure optimization in problem cases.

We execute measurements of mechanical and electrical variables with static and dynamic loads under operating conditions, install complete measurement chains including the process adaptation. Our many years of experience guarantee effective problem solutions for status, condition and load analysis.

We can support you with long-term measurements for data acquisition in actual operation, for example for the assessment of the impact and effects on the service life or the operating strength verification.

Our on-site measuring service can provide numerous possibilities: with high channel counts and sampling rates, harsh environmental conditions, autonomous measuring in the regular utilization or under test conditions – we can provide you with as much measurement data as you require.

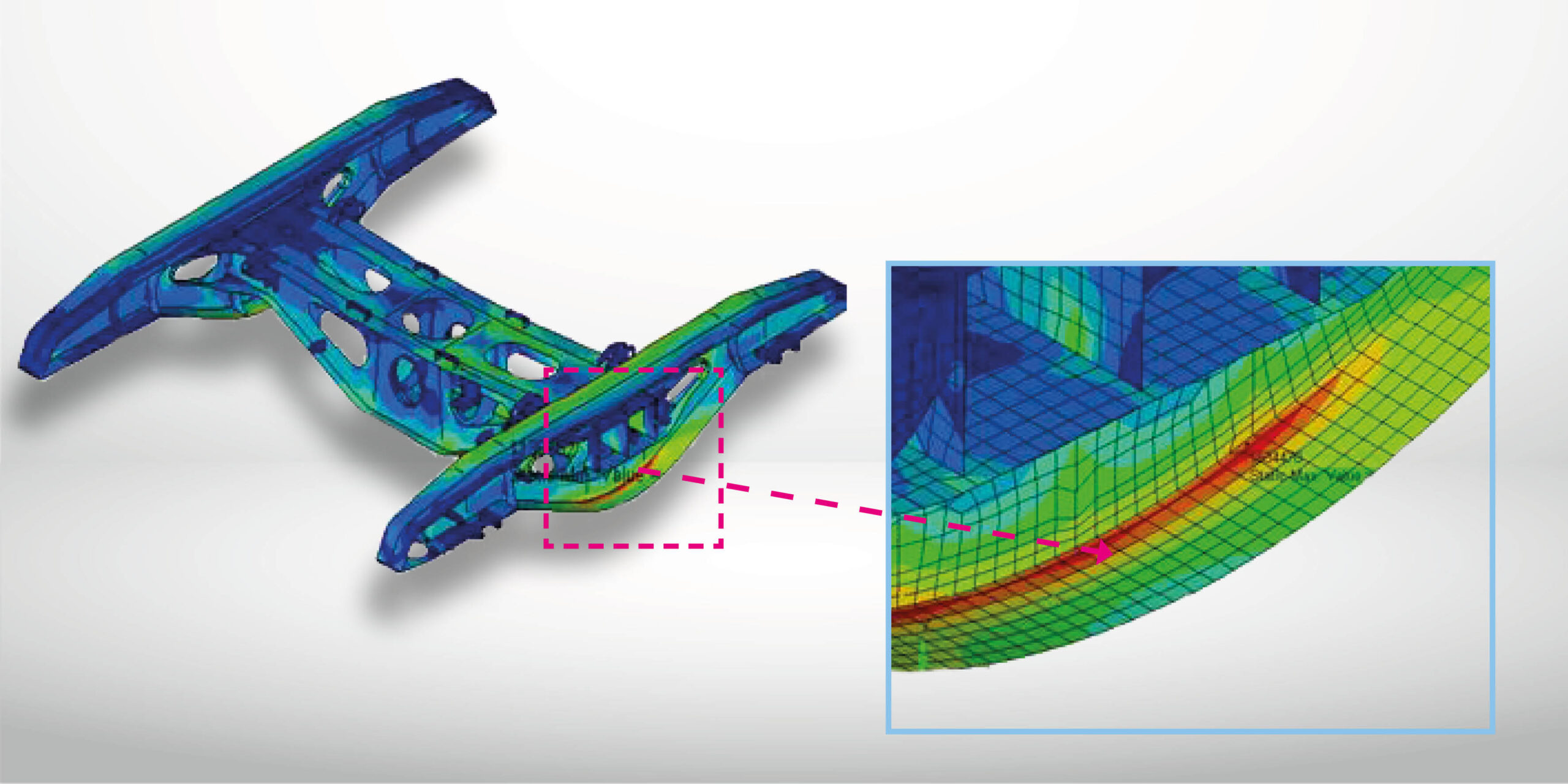

FEA Analysis

Experienced calculation engineers from the fields of statics, operational strength and dynamics are on hand to optimize your product by scaling its mass and form on the basis of FE analysis. We determine stresses and deformations, examine the stability behavior, obtain static, operational and permanent strength verifications, evaluate natural modes and resonances, and analyze and assess damage.

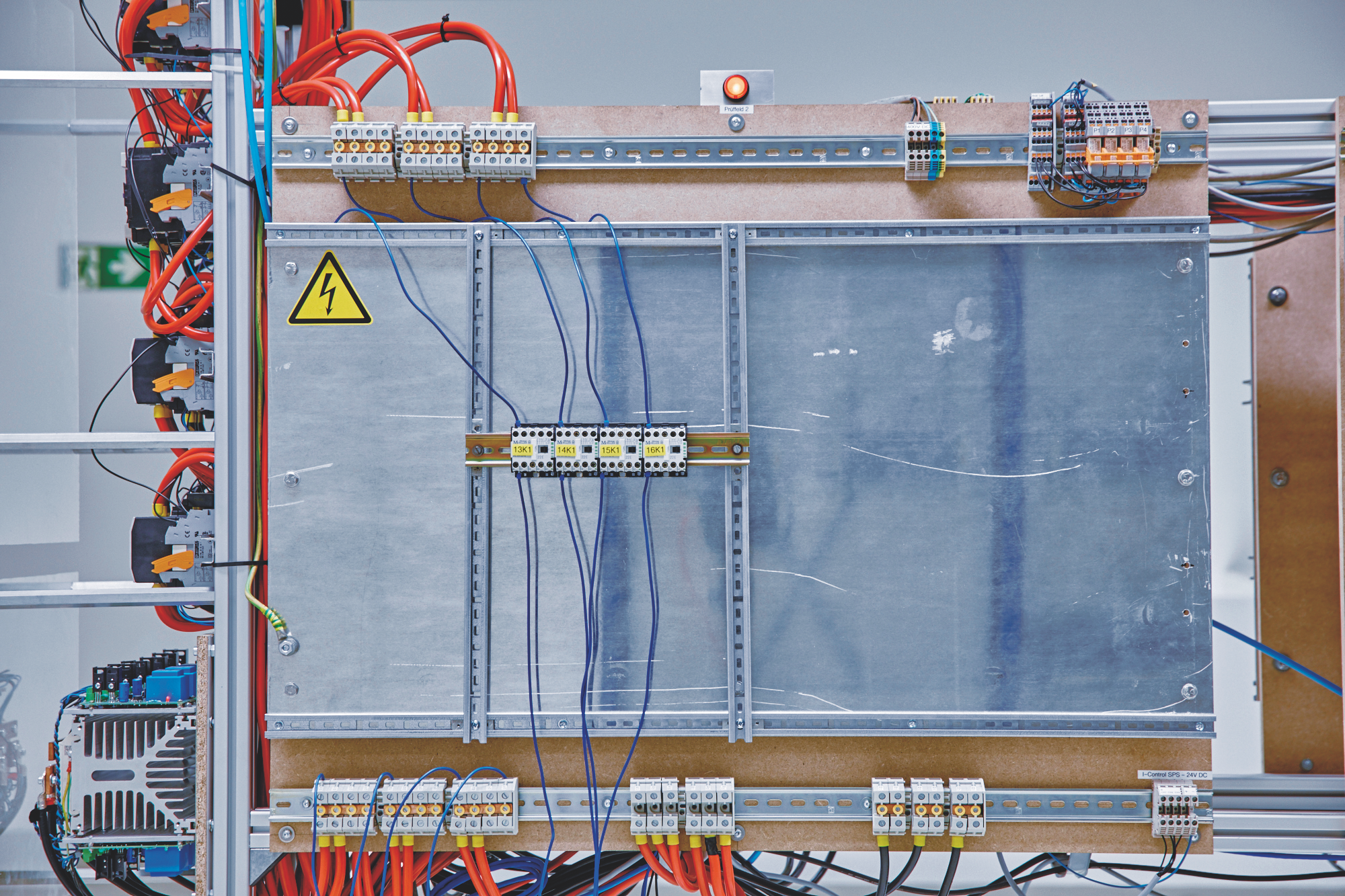

Electrical Tests

Whether you need short-circuit, short-time withstand current capacity, switching capacity or continuous current testing, in our testing facilities test currents are PLC controlled and data such as current-voltage curves and temperatures are recorded.

From switch-fuse units and terminal blocks via battery connectors through to complete control cabinets – you can expect comprehensive engineering competence in development tests and type testing with an extensive range of services in the high-performance test field.

Railway Damage Analysis

Despite new, innovative production technologies and manufacturing routines, cases of damage are still occurring as a result of product defects, installation errors or incorrect operation.

Causes may be material based and/or production related. In addition, a faulty design can cause product failure or damage can result from loads or external influences. In some industries, a tolerance for damage also belongs to the safety concept.

Through a rigorous systematic approach, we can examine the direct cause of the damage by utilizing material analysis methods. Our experienced materials engineers will assist you in order to determine the cause of damage to your machinery, systems, plants and components.