Rail Testing Laboratories

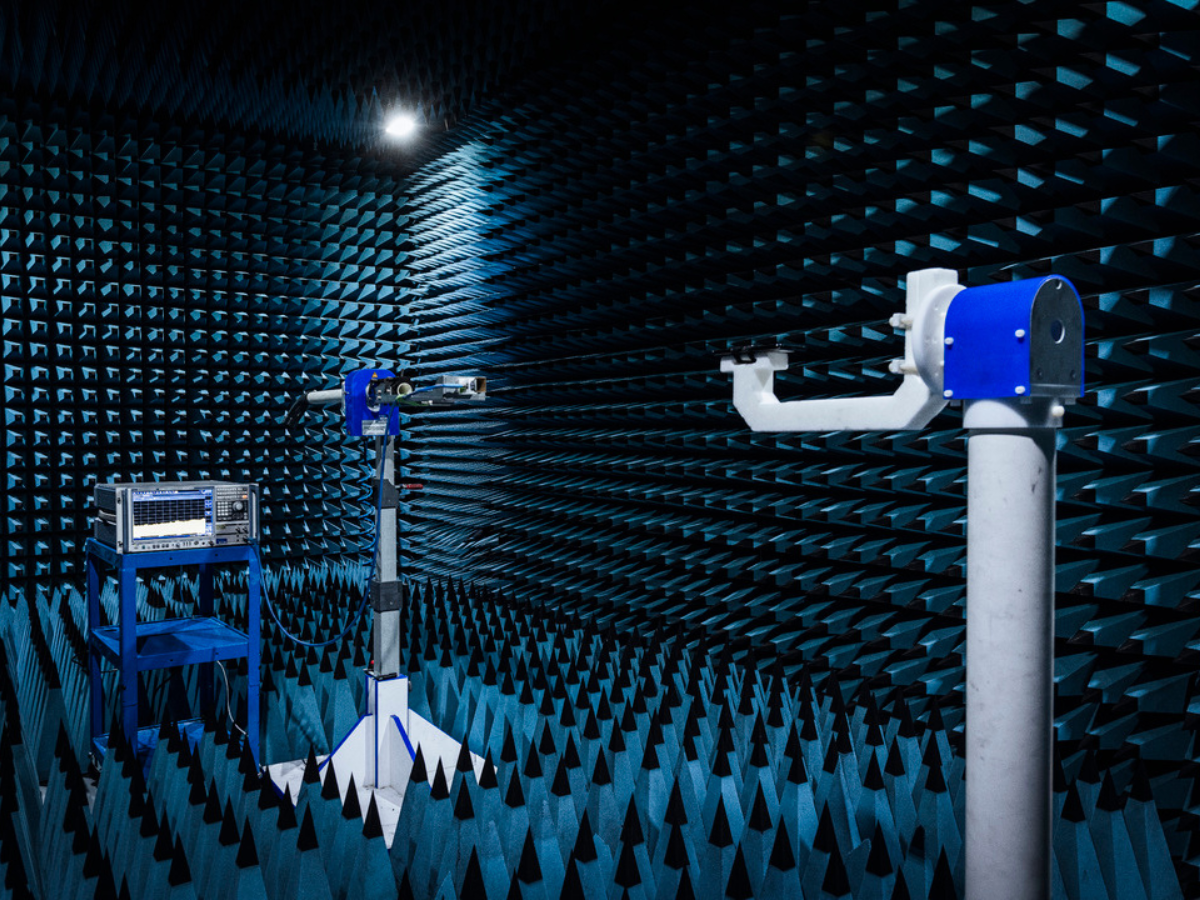

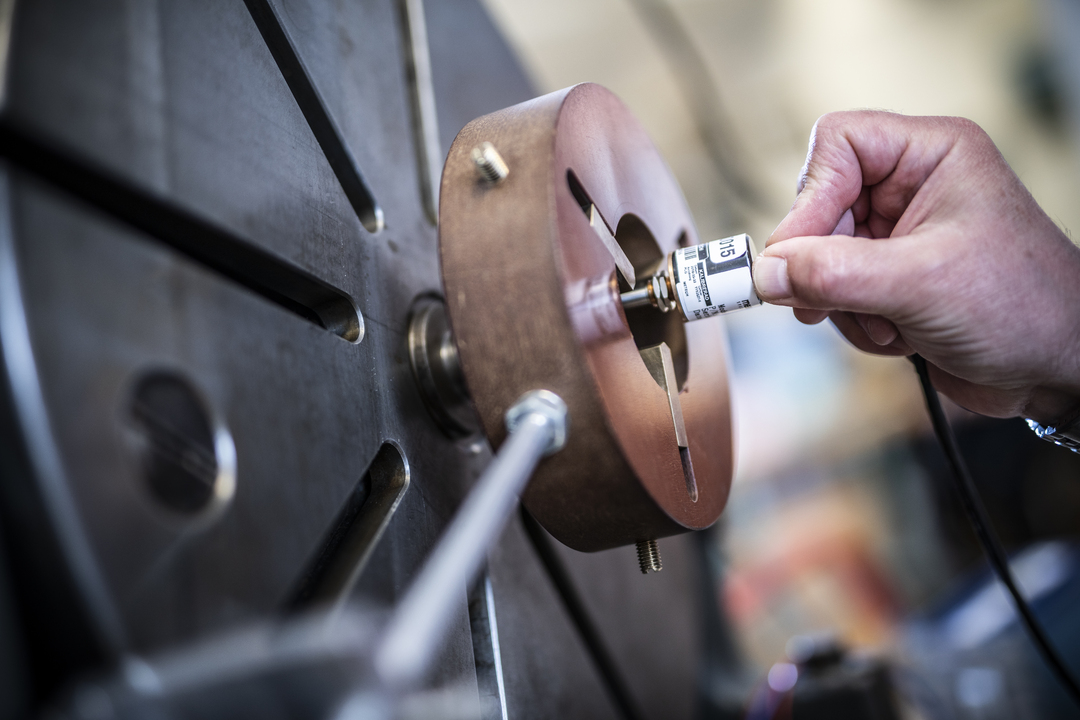

Element’s rail testing laboratories are equipped with industry-leading technology, including customisable train simulation programmes, high-capacity weld strength testing, abrasion and corrosion evaluation, metallurgical inspection, and full-service rail fire testing capabilities from Warringtonfire.

Our team has decades of experience and deep knowledge of the field, our experts provide guidance and results you can trust while helping you complete your project on time.

Element’s expanded network of nearly 6,000 engaged experts operates from 180 laboratories in 30 countries around the globe. We are one of the world’s leading providers of testing, inspection, certification, and advisory services for a diverse range of materials and products.

Our purpose is to help make certain that the materials and products we test, inspect, and certify are always safe, quality, compliant, and fit for purpose.

Rail Tracks and Infrastructure Testing

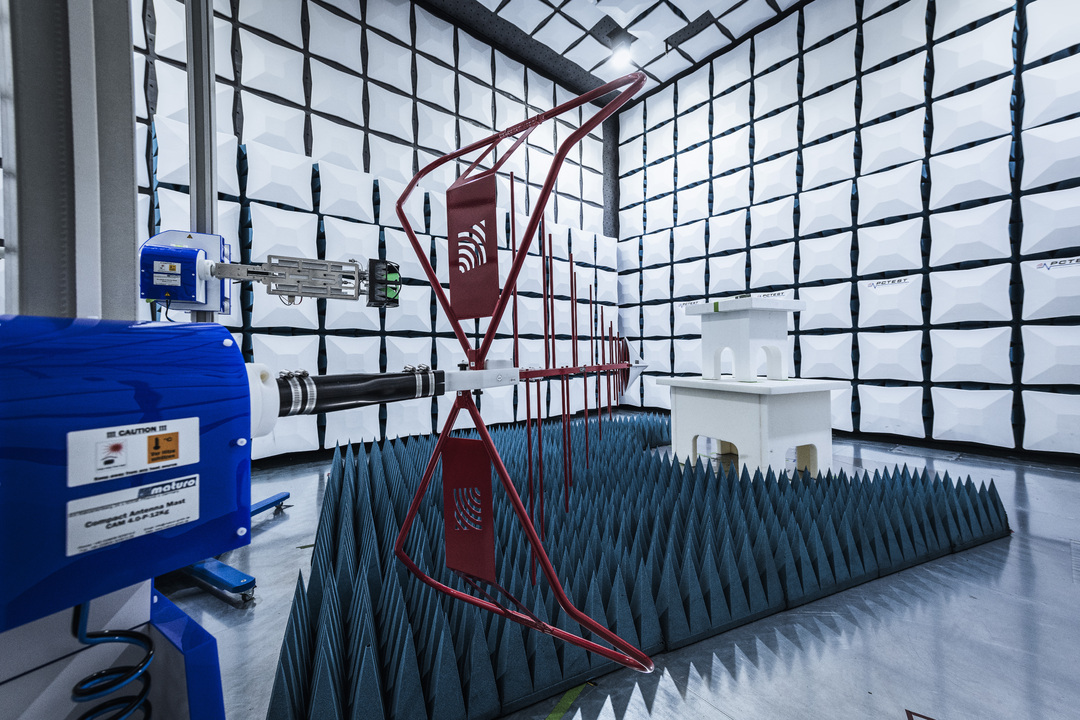

Our labs use our full range of ISO 17025 accredited destructive testing, non-destructive testing, and failure analysis services to determine these materials’ properties, performance, strength, and durability. We help our customers to select and to apply the best material for their project, increase their overall quality and reliability to minimise service failures, and reduce costs.

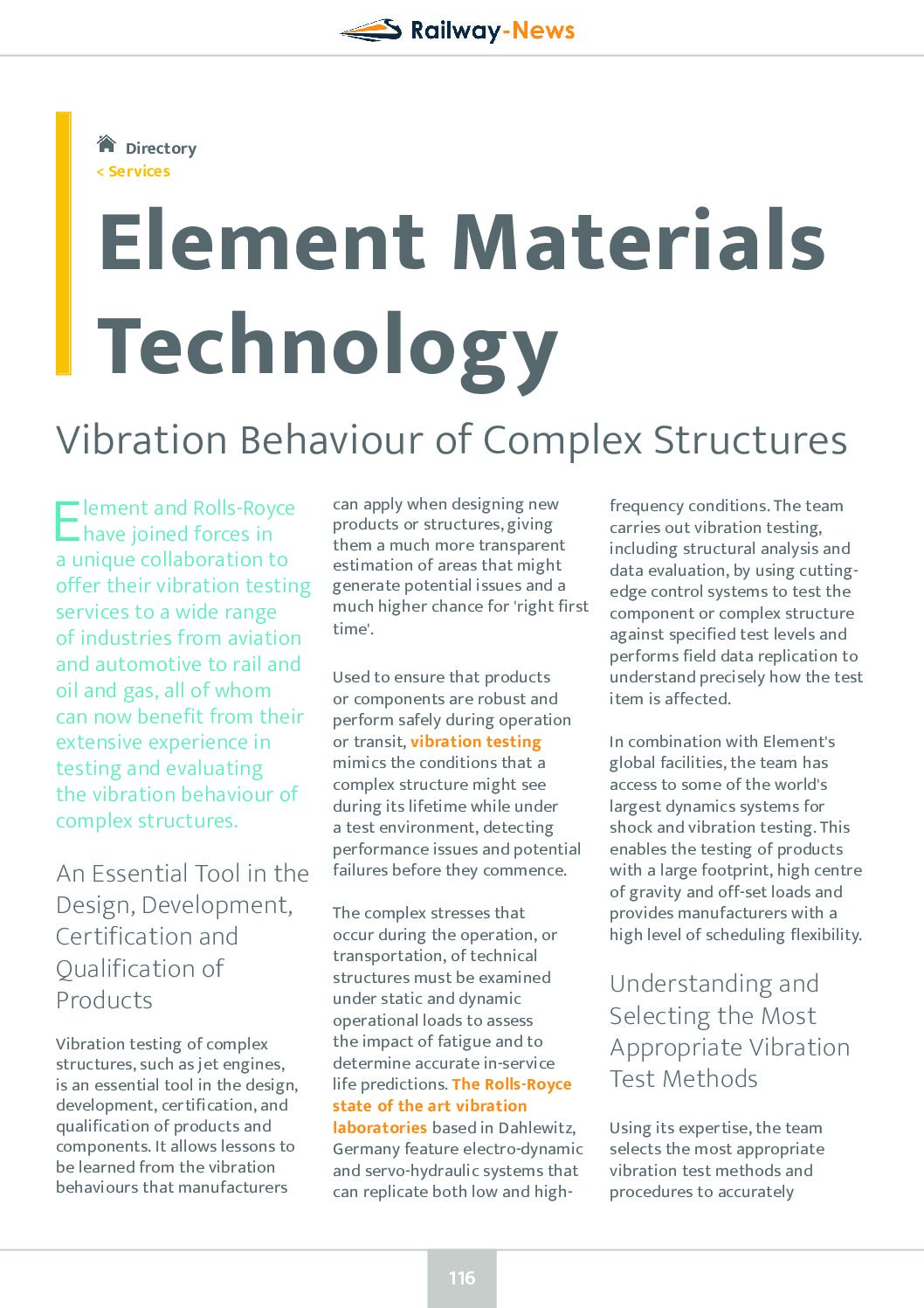

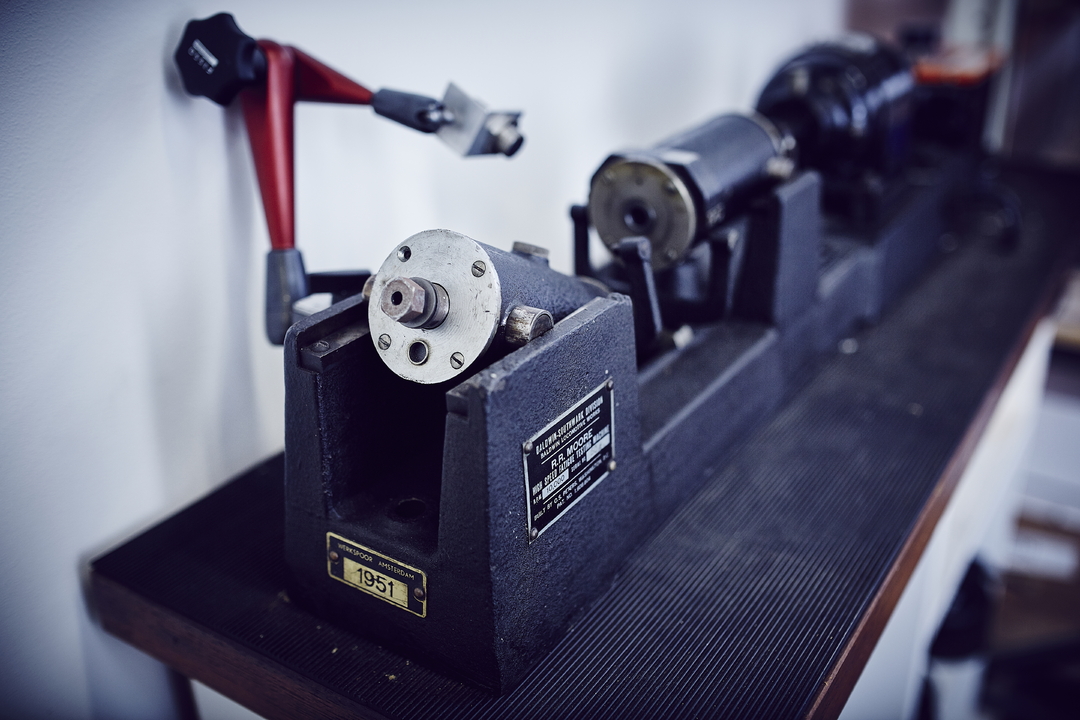

Rail Component Testing

Element partners with manufacturers and operators to provide rail component testing to ensure that products are safe and adhere to international rail regulations. Our global footprint allows us to deliver testing quickly and efficiently at a convenient location for our customers, enabling you to save time and avoid any costly project delays. Testing rail components also provide stakeholders with confidence that your products have been tested to the highest rail standards.

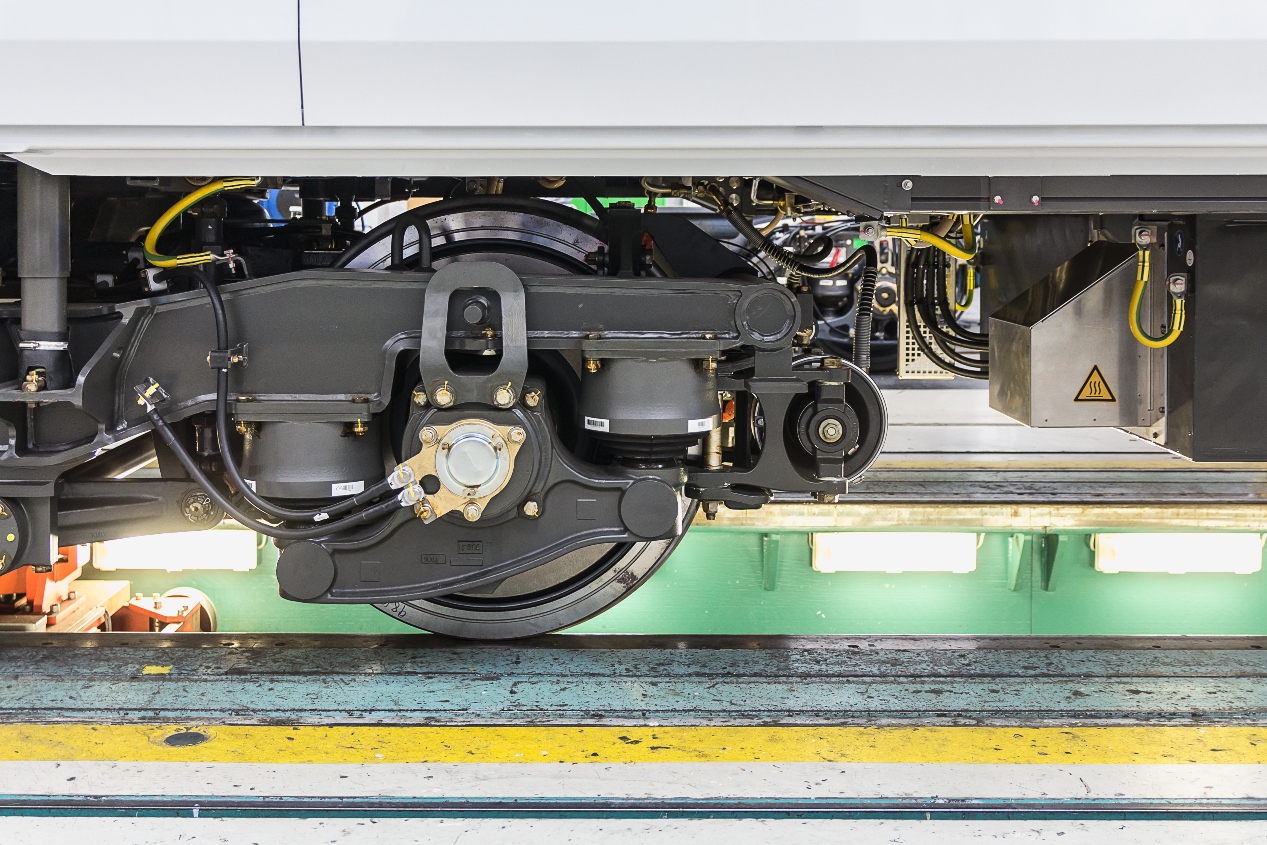

Rolling Stock Inspection

Rolling stock rail inspection services focus on the condition of in-service vehicles incorporating a component, system, or entire train to deliver an independent view of its relative condition against expectation.

Our ISO/IEC 17025 accredited laboratories offer the railway industry high-quality technical services, together with industry-leading turnaround times that enable our customers to meet their project deadlines consistently. We are leaders and innovators in materials and product testing and have one of the world’s largest independent testing capacities.

Element specialises in testing many grades of steel, composite materials, additively manufactured components, components, and systems widely used throughout the rail industry.

Full-Service Rail Fire Safety

Warringtonfire is proud to be part of the Element group, and provides a comprehensive range of independent rail fire testing services to a global market from its UKAS accredited testing laboratory in Warrington, DAkkS accredited laboratory in Frankfurt, and our BELAC accredited testing laboratory in Gent.

We help our customers achieve a holistic view of rail fire testing standards through the provision of a full-service offering that includes: developing fire safety design strategies, through rail fire testing and certification of fire protection products, to inspection, commissioning, and certification of completed projects.

Download our Fatigue and Fracture Toughness in the Rail Industry white paper.