Element Materials Technology

This article first appeared in the Railway-News Magazine Issue 1, 2022.

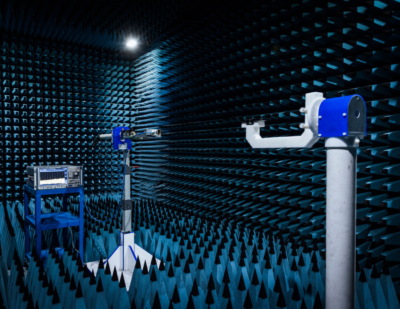

Element and Rolls-Royce have joined forces in a unique collaboration to offer their vibration testing services to a wide range of industries from aviation and automotive to rail and oil and gas, all of whom can now benefit from their extensive experience in testing and evaluating the vibration behaviour of complex structures.

An Essential Tool in the Design, Development, Certification and Qualification of Products

Vibration testing of complex structures, such as jet engines, is an essential tool in the design, development, certification, and qualification of products and components. It allows lessons to be learned from the vibration behaviours that manufacturers can apply when designing new products or structures, giving them a much more transparent estimation of areas that might generate potential issues and a much higher chance for ‘right first time’.

Used to ensure that products or components are robust and perform safely during operation or transit, vibration testing mimics the conditions that a complex structure might see during its lifetime while under a test environment, detecting performance issues and potential failures before they commence.

The complex stresses that occur during the operation, or transportation, of technical structures must be examined under static and dynamic operational loads to assess the impact of fatigue and to determine accurate in-service life predictions. The Rolls-Royce state of the art vibration laboratories based in Dahlewitz, Germany feature electro-dynamic and servo-hydraulic systems that can replicate both low and high-frequency conditions. The team carries out vibration testing, including structural analysis and data evaluation, by using cutting-edge control systems to test the component or complex structure against specified test levels and performs field data replication to understand precisely how the test item is affected.

In combination with Element’s global facilities, the team has access to some of the world’s largest dynamics systems for shock and vibration testing. This enables the testing of products with a large footprint, high centre of gravity and off-set loads and provides manufacturers with a high level of scheduling flexibility.