Axle Counter and Telecom Cables

British Cables Company Limited is a member of the Wilms Group with manufacturing and commercial operations in the UK that supports and supplies a global client base. It has a comprehensive cable and accessories product portfolio which enables it to effectively service many market sectors including telecommunications, utilities, infrastructure, buildings, industrial and rail.

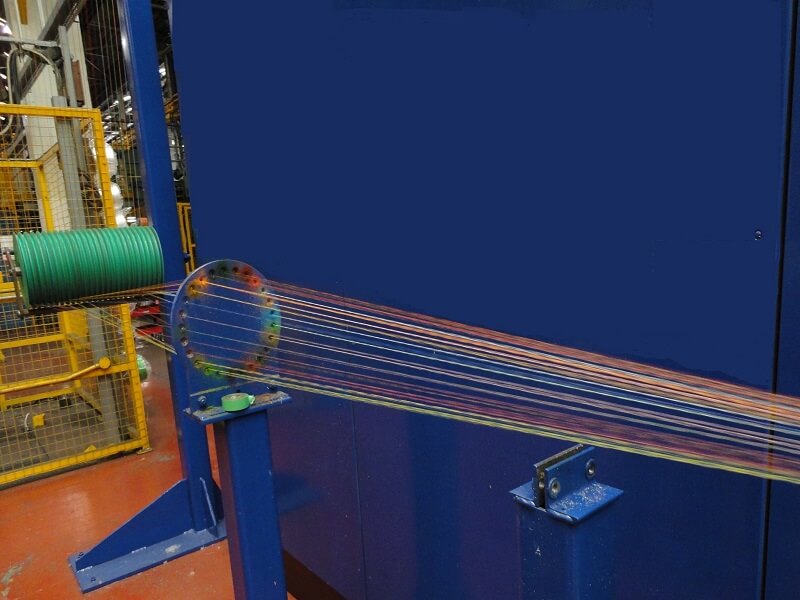

Cable manufacturing at its Manchester plant is steeped in history with the factory being continuously operational for more than 120 years, this longevity brings invaluable experience and expertise which has seen the operation evolve to what it is today – a world class, industry-respected cable manufacturer and supplier.

The BCC business philosophy is simple:

- Understand our customers’ needs!

- Develop solutions to meet those needs!

- Ensure we deliver first-class quality products, on time, every time!

British Cables Company operates world-class manufacturing facilities and manages a successful global supply chain. BCC has designed and delivered a host of innovative new services and solutions. As an extremely customer-centric business, these services are specifically designed to take cost and overhead out of the supply chain.

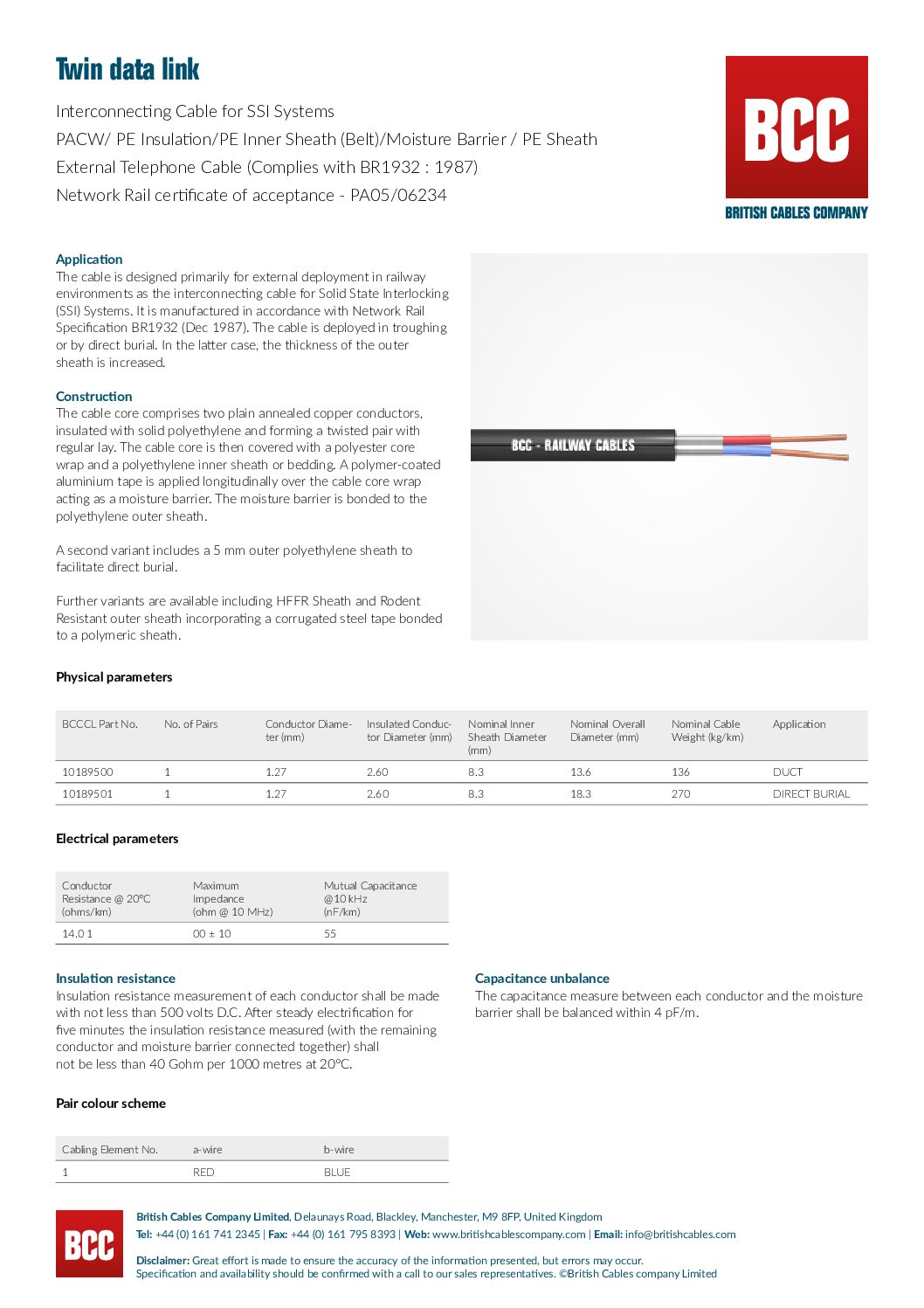

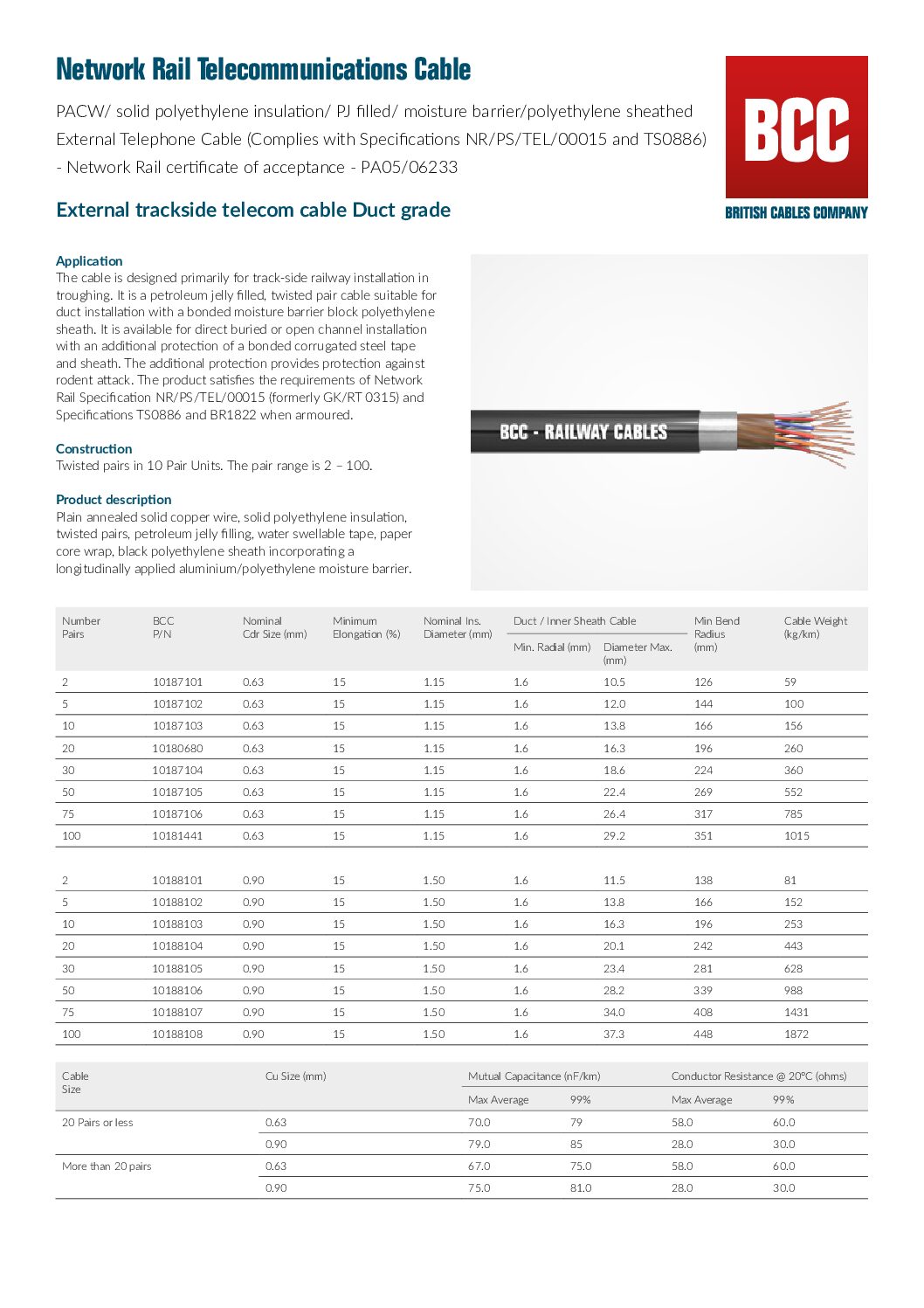

Network Rail Approved Axle Counter and Telecom Cables

British Cables Company will continue to invest in the development of its product range and services with a specific focus on the rail market. BCC currently holds Network Rail approvals for:

- Axle counter (NR/L2/SIG/30060)

- Trackside telecoms (NR/PS/TEL/00015)

- SSI datalink (BR1932)

- Internal low smoke telecoms (CW1600)

- Jumper wires (CW1423NR)

Based in Manchester, British Cables Company has been manufacturing telecoms and rail cables on this site since 1895. It has a total footprint of 113,000m2. BCC introduced its Continuous Improvement philosophy under the Kaizen umbrella in 1998. Continuous improvement is an established way of life within British Cables Company. Kaizen and Six Sigma have become fundamental to BCC’s continued growth and success. By putting these techniques at the heart of strategy, planning and operations, all areas of our business have seen significant improvements in:

- Business efficiency

- Minimising waste

- Cost reduction

- Delivery for customers

- Health and safety

British Cables Company’s extensive skill base in continuous improvement techniques has been made available to its customers and suppliers. Using BCC’s expertise, customers have been able to ‘fast track’ the benefits of Kaizen within their own organisations. Kaizen is also employed throughout our extended supply chain. Today the facility provides services from cradle to grave for cable from manufacturing, cut-to-length, next day delivery anywhere in the UK, drum management and recycling services.

Service Solutions include:

- Inventory management

- Cable cutting

- Distribution

- Drum management

- Cable recycling and waste management

Environmental Responsibility

British Cables Company is one of the few companies within the industry to have an Environmental Manifesto. The company is ISO 14001 certified and fully compliant with RoHS requirements. BCC offers a full range of HFFR cables and has also achieved some notable environmental milestones in recent times including a reduction of 3% in power consumption, the substitution of wooden battens by plastic wrapping (50%), the redesign of wooden drums to reduce the wood consumption (15%), collection of 70% of drums to be re-used in the domestic market and most significantly there have been no environmental claims received for more than 10 years. Furthermore British Cables Company is working with The Carbon Trust, Groundwork EBS and The Manufacturing Institute to calculate its carbon footprint and reduce its impact on the environment by up to 25% in the next 10 years.

Why Make British Cables Company Your Cable Manufacturer and Supplier of Choice?

- Confidence – As a sole supplier to Openreach for many years BCC has proved itself as a capable and reliable business partner.

- Competitive prices – industry benchmarking means all British Cables Company customers can be assured of best value for money.

- Products and Service – a comprehensive range across key market sectors.

- Cable handling and logistics – providing end to end solutions.

- 120 years plus – experience and expertise. We know better than most how to make cables!

- Philosophy and promise – you know what to expect from BCC.

- Supply chain efficiencies – keeping costs under control.

- Protected – Business Continuity Plan to ensure supply to our customers in any event.

British Cables Company is an organisation with huge geographical reach, global know-how and exceptional equipment efficiency. BCC is a copper and optical fibre cable manufacturer and supplier, whose products build the vital connections that support the way we live, work and relax in the 21st Century. Its products form the core of intranet, internet and other communications networks all around the world; they are the backbone behind transport communications links, they are critical to building management, they are a critical link in industrial environments and they bring heat and light into homes and business.

Supply Partnerships

Complementing British Cables Company’s in-house manufacturing facility is a programme of supply partnerships with high-quality manufacturing companies across Europe and Asia. These relationships have been built up over many years with the result that exceptional quality and service are achieved.

This extended supply chain adds strength and diversity to BCC’s manufacturing capability. Our team based in Asia ensures the highest levels of product quality are assured. A rigorous product inspection and release programme, regular audits and a commitment to work with our partners to continually reduce waste and take cost out of the process, provide further evidence of British Cables Company’s investment in its global supply chain. BCC’s experienced technical team can facilitate timely new product introduction with our supply partners and dramatically increases the scope of the product portfolio British Cables Company can offer. Encompassing the full end-to-end supply chain our Corporate & Social Responsibility programme represents BCC’s philosophy of only working with supply partners who share a similar vision. This is enforced by regular assessments by the team.