ALFA Sentry Dams are reusable, repairable, and sustainable.

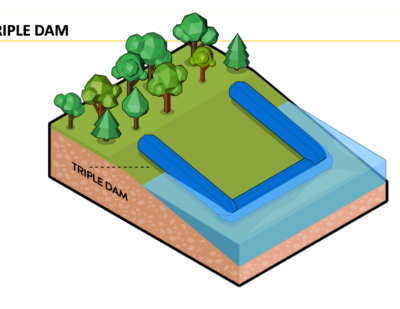

No pump needed! Simply set the system up, then make sure the lower part is anchored and the compression legs are on a solid surface.

The patent-pending, self-supporting design is available in two heights. Both sizes can achieve a working water depth up to the product height of either: 0.6 m (24”) or 1.06 cm (42”). Full working water depth requires firm subsoil.

Supplied in 7.62 meter (25′) long sections, assembled with a combination zip/hook and loop coupling, allowing the barrier to be extended to the required length.

ALFA Sentry Dam Material

Made from high quality recyclable materials.

- Repairable – Accidents happen, but our industrial coated PVC fabrics are repairable.

- Responsible – No environmental impact during installation. No filler material is required. This eliminates the need to filter or dispose of used and/or contaminated filler materials.

- Secure – Integrated stabilizing structural components prevent sliding or tipping.

- Durability – Polyester-based fabric with high tensile strength is coated with flexible PVC that is resistant to the effects of chemicals, UV radiation, mold, and mildew.

Product Specification

- High tensile strength woven polyester, PVC coated fabric.

- Aluminum components integrated.

- Standard section length is 7.6 m (25′).

- Standard section heights are 0.6m (24”) and 1.06m (42”).

This article was originally published by Argus Fluidhandling.