3A Composites Mobility: Structural Metro Floor – XBODY® Metro

- What is this product about?

XBODY® Metro is a structural flooring solution for metro vehicles. This structural sandwich floor is the replacement for conventional welded extruded aluminum profile floors.

- What materials are used?

XBODY® Metro uses a sandwich composition with aluminum edge profiles, aluminum cover sheets, PET foam core and a special designed fire protection layer.

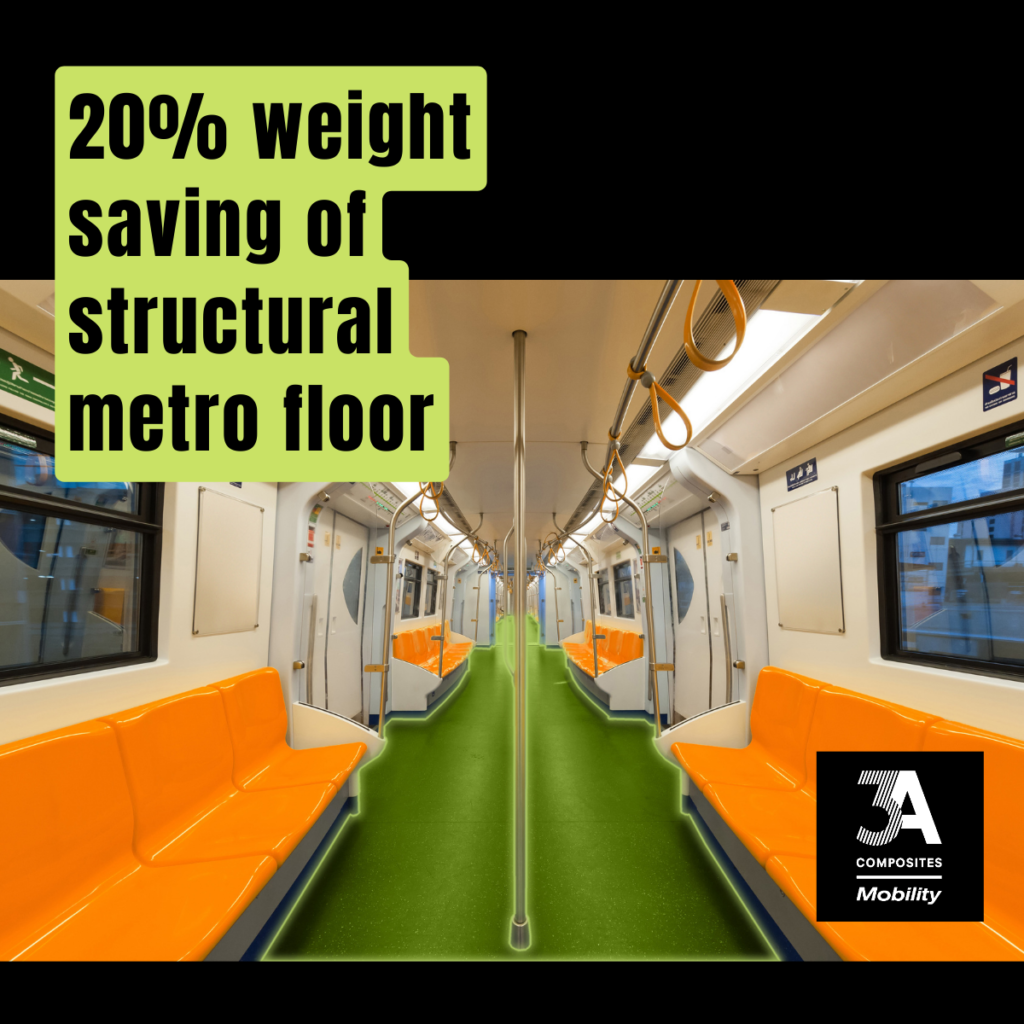

- What is the weight reduction compared to the standard product?

For metro vehicles, with a length of 22 meters, a saving of 20% of the weight of the structural metro floor is achieved.

- What are the benefits for the metro manufacturer?

The main savings are in car weight, cost and assembly time savings, modular design, and is highly fire resistant to ASTM 119. The XBODY® Metro design allows the aluminum structural floor and the interior passenger floor to merge, reducing to a single lightweight component.

- How is the structural floor for metros installed?

This XBODY® Metro floor can be welded, riveted, bolted, or glued to the car structure. The one-piece weight of the XBODY® Metro can be laid by the open ceiling assembly method, or through simple placement of each individual module by installation personnel.

- What possibilities exist for recycling of this structural floor?

Every component, such as aluminum covers, aluminum side profiles and thermal foam core can be separated and recycled accordingly.

Find out more at: www.3acompositesmobility.com.

With more than 60 years of experience in manufacturing composite systems for a wide range of industries, the internationally renowned 3A Composites Mobility, part of Schweiter Technologies, is moving into the future with innovative solutions.