Following investigation of a suitable alternative fuel, undertaking several successful trials in April 2021, the time was right at the start on May 2021 to change from a mineral based fuel to a greener sustainable alternative, HVO fuel.

What Is HVO Fuel?

HVO fuel is one of the cleanest fuels on the market. It’s a second-generation, synthetic, advanced renewable diesel alternative that eliminates up to 90% of net CO2 and significantly reduces nitrogen oxide (NOx), particulate matter (PM) and carbon monoxide (CO) emissions. As a paraffinic, renewable fuel, HVO can be used as a drop-in alternative to fossil diesel. There’s no need to modify existing infrastructure – you can simply top up and go.

Why?

- Sustainable fuel.

- Gas emissions reduction of up to 90%.

- Fully biodegradable.

- No need to modify existing infrastructure – you can simply top up and go.

- Unlike other fuels in an emergency fossil diesel can be added without any issue.

- Meets EN 15940:2016 specifications and endorsed by a wide range of OEMs.

How Is HVO Better Than Mineral Diesel or Fame (Fatty Acid Methyl Esters) Fuel?

- As a synthetic product, HVO’s molecules are consistent and uniform which allows HVO to perform much better in several areas

- Cleaner burn reduces emissions

- Improved cold temperature performance – improves cold start properties in winter .

- Better combustion and filterability than other diesel products

- HFRR lubricity of around 350 microns represents “best in class” compared to EN590 diesel.

- Drop-in alternative for regular diesel (conforming to EN15940) and approved by various OEMs.

- Up to 10-year shelf life, depending on the storage conditions.

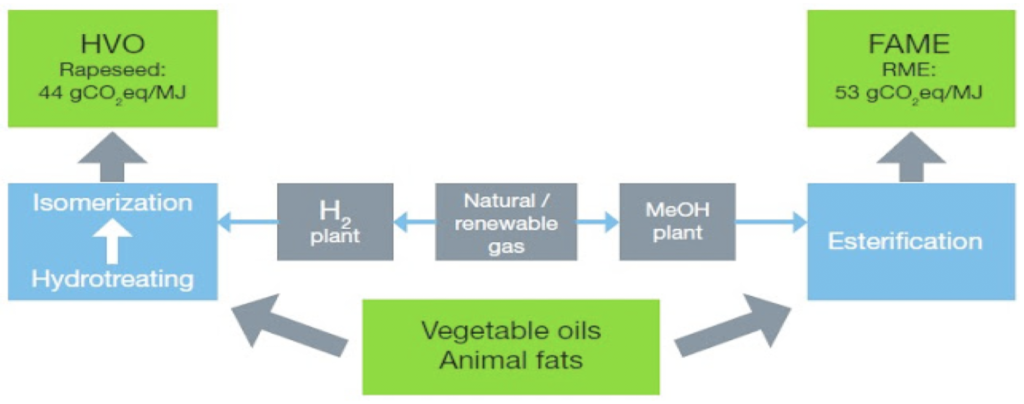

Simplified scheme showing inputs and outputs of esterification and hydrotreating processes for biofuel production considering rapeseed as feedstock

Other benefits of HVO

- Greenhouse gas emissions are up to 90% lower than mineral diesel.

- Fully biodegradable.

- Manufactured from 100% renewable raw materials.

- Bulk fuel delivery mileage is carbon offset.

- Meets EN 15940:2016 specifications.

- Tried and tested product; it’s clean, safe and endorsed by a wide range of OEMs.

- Free from aromatics, sulphur and metals .

- Excellent cold-weather performance.

- Reduced particulate production during combustion reduces the ageing of engine oils and improves cold start properties and air quality.

- Suitable for a large number of engines, generators and machinery.

Conclusion

HVO fuel is sustainable, cleaner and fully biodegradable with no additional infrastructure costs resulting in cleaner and greener SRS RRV operation, this directly benefit’s our clients, the rail infrastructure and ultimately the planet.

Further Informatiom:

- Hydrotreating is an alternative process to esterification to produce diesel from biomass. Traditionally, diesel components produced from vegetable oils are made by an esterification process. In fact, HVO are commonly referred to as renewable diesel or green diesel in order to distinguish from Fatty Acid Methyl Esters (FAME), best known as biodiesel. Other acronyms are also used depending on the feedstock, such as Rape Seed Methyl Ester” (RME), “Soybean Methyl Ester” (SME), “Palm Oil Methyl Ester” (PME) or “Used Cooking Oils Methyl Ester (UCOME).

- In the HVO production process, hydrogen is used to remove the oxygen from the triglycerides and does not produce any glycerol as a side product. Additional chemicals, like methanol for FAME production, are not needed. Hydrogenation removes all oxygen from the vegetable oils while esterification does not.

- Both FAME and HVO production processes use intermediates generated from natural gas. Figures published by the Renewable Energy Directive 2009/28/EC (“RED”) show that life cycle greenhouse gas emissions of HVO are slightly lower than those of FAME if both are made from the same feedstock.

- Properties of HVO have much more similarities with high quality sulphur free fossil diesel fuel than with FAME. As a matter of fact, the properties of renewable diesel are very similar to the synthetic gas-to-liquid (GTL) diesel fuels. Also, the same analytical methods as used with fossil fuels are valid for renewable diesel