JR East Takes Delivery of Mobile Maintenance System

Under the restrictions posed by the Corona pandemic, the traditional opening ceremony for the company’s first Robel Maintenance System took place at the Ueda depot in the prefecture of Fukushima. JR East’s decision to use these vehicles marks a change to the company’s previous path of maintenance activities that were intensive with regard to human resources and time.

The company anticipates better safety for its staff and increased efficiency in track maintenance.

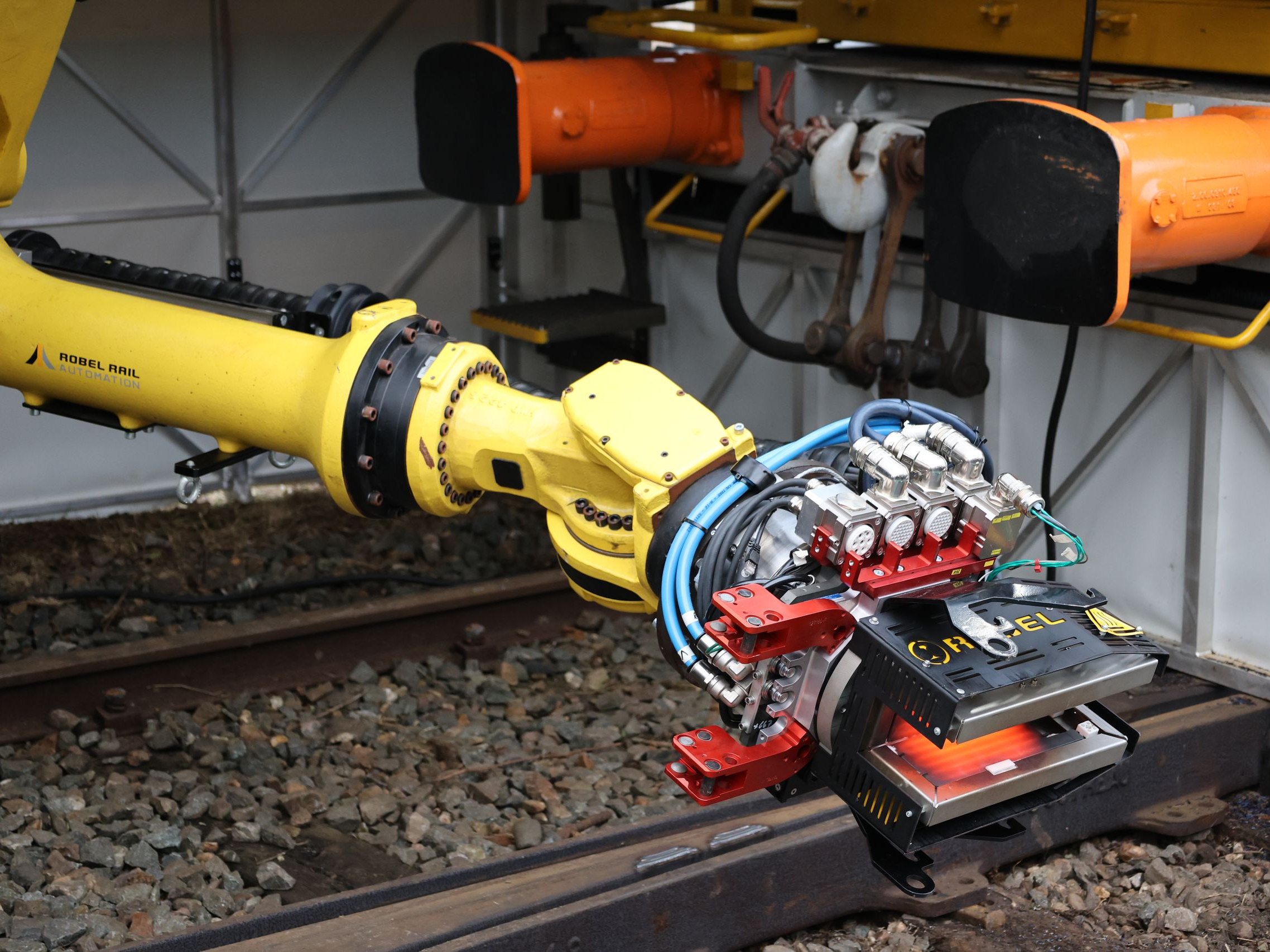

GMAC – Next Generation Maintenance Machine – is the official name of the vehicle formation consisting of Mobile Maintenance Unit and Loading Unit from Robel and a Japanese traction vehicle. The system will be deployed for maintenance and inspection activities on the Joban line from the second half of this year.

Despite the intensive use and high volume of traffic, Japan’s railways are considered the most reliable in the world. We are honoured that the Japanese network operators are positioning themselves for the future in infrastructure maintenance using our products.

The Cooperation between Robel and JR East

ROMIS is the second large-scale machine project that Robel has implemented in cooperation with East Japan Railway Company (JR East) and its sales partners Nippon Plasser Co., Ltd. and Mitsui & Co. Plant System Co., Ltd. Since 2017, the REX-S 1200 Rail Train has been used on the Shinkansen network in the East Japan. Robel will supply further machines for preventive maintenance to Japan from 2021.

For more information visit robel.com