The Goldschmidt BRB 32B – a New Generation of Road-Rail Inspection Vehicle

In Italy, RFI operates and maintains the public railway infrastructure. The maintenance of railway bridges, as part of the infrastructure, is particularly important and this also requires inspecting these bridges. Railway bridges can be classified based on the following factors:

- the crossing level of the railway line (under bridge or over bridge)

- the type of superstructure (arch bridge, truss bridge, cable-stayed bridge or suspension bridge)

- the type of material used for the construction (masonry bridge, steel bridge, RCC bridge, prestressed concrete bridge)

In RFI’s maintenance plan, a professional inspection is required to ensure the safety and permanent usability of these structures in order to operate trains according to schedule.

There are 20,000 RFI railway bridges of all kinds and around 40 percent of the total are arch bridges. The different designs naturally have material-specific properties, which must be considered during the inspection made by the RFI specialists.

RFI personnel make on-site visits to bridges as specified by UIC code 778. Scheduled visits and visits at short notice are provided for as required and are now carried out in different ways, e.g. by AWP (Aerial Work Platform), or on foot etc. to ensure that the operator is at “contact distance” from the structure being inspected.

Requirements for the Maintenance of Italian Railway Bridges

In recent years the requirements to maintain and inspect bridges have reached a high level of intensity and accuracy in order to ensure the proper operation and safety of the railways.

It became obvious that RFI must find answers to the increased demands to ensure their fulfilment. A solution was needed.

The requirements are as follows:

- track access for inspections has been reduced, because more trains are in operation and headways are higher – this needs to be handled properly

- rail service downtimes caused by inspection activities should be avoided or limited

- higher inspection productivity is required to align and synchronize activities in general, and for the inspection of railway bridges this includes:

- processing double track lines in one step, allowing the inspection platform to wrap around the parallel track (i.e. the one the road-rail vehicle is not on) underneath the bridge to enable full inspection without transferring the inspection vehicle from one track to the other track

- keeping the parallel track in operation when the track on which the road-rail vehicle is placed is blocked for train traffic

The Goldschmidt BRB 32B

The Goldschmidt Group is a global solution provider in the railway business. The Goldschmidt companies SRS (Sweden) and Thermit Italiana (Italy) are very wellknown as reliable business partners, providing innovative products and smart rail solutions to their customers.

In 2018, RFI approached potential suppliers in Europe with their request to improve the inspection of railway bridges. In the end, RFI were convinced by Goldschmidt’s offer. Their innovative products in the segment of road-rail bridge inspection vehicles were able to fulfil the high-end requirements from RFI and even more.

SRS and Thermit Italiana established a partnership with the Italian partner Barin S.r.l., market leader in the manufacture of telescopic booms. This cooperation resulted in the development of a new generation of technologically advanced road-rail bridge inspection vehicles in a short time which meet the technical specifications of RFI.

In Q3 of 2019, the first vehicle was delivered to RFI. In Q4, the RFI staff were trained. After the successful validation and acceptance, the roadrail vehicle entered service.

The Goldschmidt BRB 32B fulfils the state-of-the-art technical requirements to maintain and inspect railway bridges in the best way possible.

The key performance elements of this vehicle are:

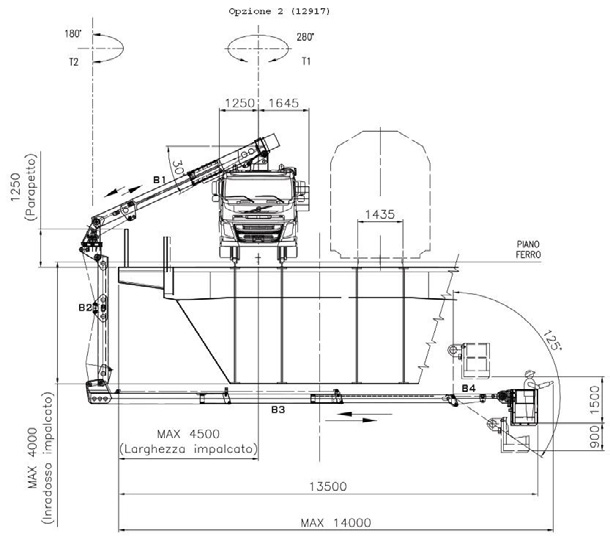

- The inspection platform combination reaches downwards 17m, upwards 10m and in the lateral direction 14m. It can wrap around the bridge and turn 280 degrees with the main turret (T1) for a bridge wrap-around inspection.

- The specially developed safety control system guarantees the inspection work under a deenergised overhead catenary without tearing it. Trains on the parallel track can operate during the inspection.

- The special tilting platform is characterised by the continuous measurement of its inclination. When high values are reached, which can endanger the safety of the operators in the basket, self-levelling is activated, and the basket is brought back to level. Moreover, it is possible to control the movement of the entire vehicle directly from the basket, in order to make short precision movements at low speed (3km/h), but always with the consent of the SIFA (consensus) pedal placed in the front cabin.

- No side supporting legs are required to stabilize the vehicle, another aspect which allows continuous inspection.

- Due to its axle weight of less than 16 tonnes, the vehicle can run on all Italian railway lines.

- The vehicle is approved for driving on the road up to 90km/h, which enables a quick transfer to the designated railway track access point.

- The SRS patented hydrostatic propulsion-driven boogie in combination with the rear cabin allows reverse driving at 60km/h on rail track.

- The vehicle can be controlled on the track from the front and rear cabin but also from the basket.

- The two-minute solution to go on or off track efficiently limits the track possession of the vehicle and minimises interference to train operation.

- The telemetry system allows remote status control by the manufacturer.

Smart Rail Solutions for the Success of Our Customers

The high technological standard of the product allows RFI to greatly increase the effectiveness and efficiency of inspections on railway bridges. The system reduces the time it takes for operators to reach the bridge and enables inspections on both sides of the bridge while remaining on the same track.

The success of this project was connected to the close collaboration between the parties. This included SRS with its technical expertise based on long-term experience of all kinds of road-rail vehicles, Thermit Italiana with its understanding of the Italian market, and Barin with its high-performance telescopic arm. All this, including the excellent co-operation between Goldschmidt and RFI, has made it possible to develop the product successfully.

Six more vehicles will be delivered to RFI in the course of the year.

This article was originally published by Goldschmidt.