Network Rail has announced that throughout October it has been performing comprehensive testing to determine whether laser beams and superheated plasma jets could be effective at clearing leaves off the line.

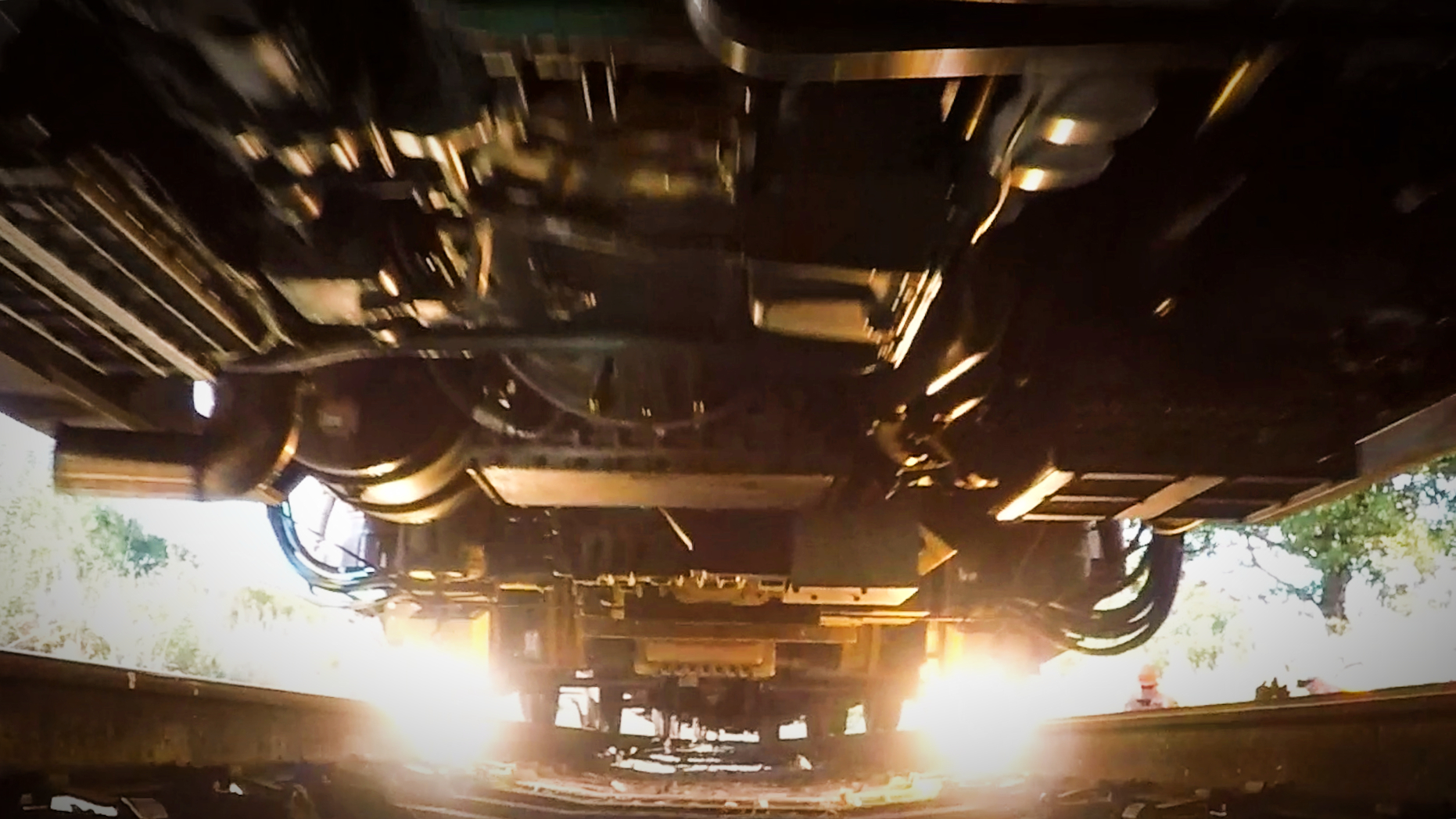

The equipment has been fitted to Network Rail’s multi-purpose vehicles and has been deployed on heritage lines at the East Lancashire Railway. The standard method for removing leaves off the line is to use high-pressure water systems.

Compressed leaves on the line are a real problem for the railway as they form a black Teflon-like residue that makes it harder for trains to brake and accelerate. Leaves can cause ‘wheel slide’, a factor that was involved in last year’s Salisbury Tunnel Junction collision.

Suhayb Manzoor, Network Rail Project Engineer, said:Leaves on the line are often seen as a joke on the railway but they can cause serious problems and we’re always looking at new ways to tackle this age-old problem.

It’s also not unique to Britain, with railways all over the world having issues when trees shed their leaves. For that reason, it’s exciting to be putting some of the newest technology out there to the test with the hope that one day it could help Network Rail keep passengers and freight moving safely at this operationally challenging time of year.

Two different companies are involved in these trials: Laser Precision Solutions and PlasmaTrack.

The laser option uses three high-powered laser beams per railhead to treat the rails. The intensity of the lasers hitting the railhead causes the contamination to instantly vaporise (ablate) without heating up the rail.

The plasma option uses direct current plasma technology. Here heat and active electrons split things apart. The high-energy electrical plasma beam tears apart the leaf layer as well as heating and burning it off.

Currently, Network Rail’s leaf-blasting trains cover a million miles between October and December, treating the entire network 50 times over. This process uses around 200 million litres of water. Both of these options currently being trialled could reduce the amount of water consumed and the fuel required to transport it around the country, meaning a positive environmental shift and a reduction in costs to the taxpayer.

If the tests determine that lasers or plasma can clear the rails effectively, Network Rail will do further development work to learn whether these options could work on the complexities of the live railway network.

Network Rail further said that there would have to be additional studies to look into the business case for adopting a new technology.

Ben Medendorp, Laser Precision Solutions Head of Finance and Commerce, said:Normally you really have to move mountains to get access to a railway network, so having a testing site like this which is secluded where you can take measurements every day is essential to gather data.

I really do think that Network Rail is taking a leadership role in the industry by solving this global issue of low railhead adhesion. We are proving technologies and learning valuable lessons that could help railways around the world.

Julian Swan, PlasmaTrack Chief Executive Officer, said:Having three weeks of uninterrupted testing available on an operational railway isn’t usually possible so being able to carry out these trials with Network Rail and East Lancashire Railway have been invaluable.

We’ve learnt a lot on how the autumn treatment trains (MPVs) currently operate, and how the PlasmaTrack system could benefit train wheel traction and protecting wheel-slide caused by leaves on the line.