In many industrial sectors, the use of composite materials and thin sheet metal represents a challenge when it comes to fastening.

These materials, which often do not have the thickness required for threading, are not able to easily support traditional fasteners or inserts.

This is a common problem for manufacturers, equipment suppliers and maintenance workshops, especially in industries where high-strength, lightweight materials such as composites are increasingly used.

The problem is highlighted when composite panels are attached to metal structures, requiring secure solutions.

J. LANFRANCO & Cie has designed a range of innovative fastener solutions specifically to meet the challenges faced in industries using composites and thin metals.

By developing modular fixtures with unidirectional and multidirectional movement capabilities, the company offers a highly efficient and cost-effective alternative to traditional methods.

These solutions remove the need for costly processes such as laser cutting or complex machining, while providing precision fastening with tolerances as tight as 0.5mm. This not only ensures precision, but also significantly reduces overall manufacturing costs.

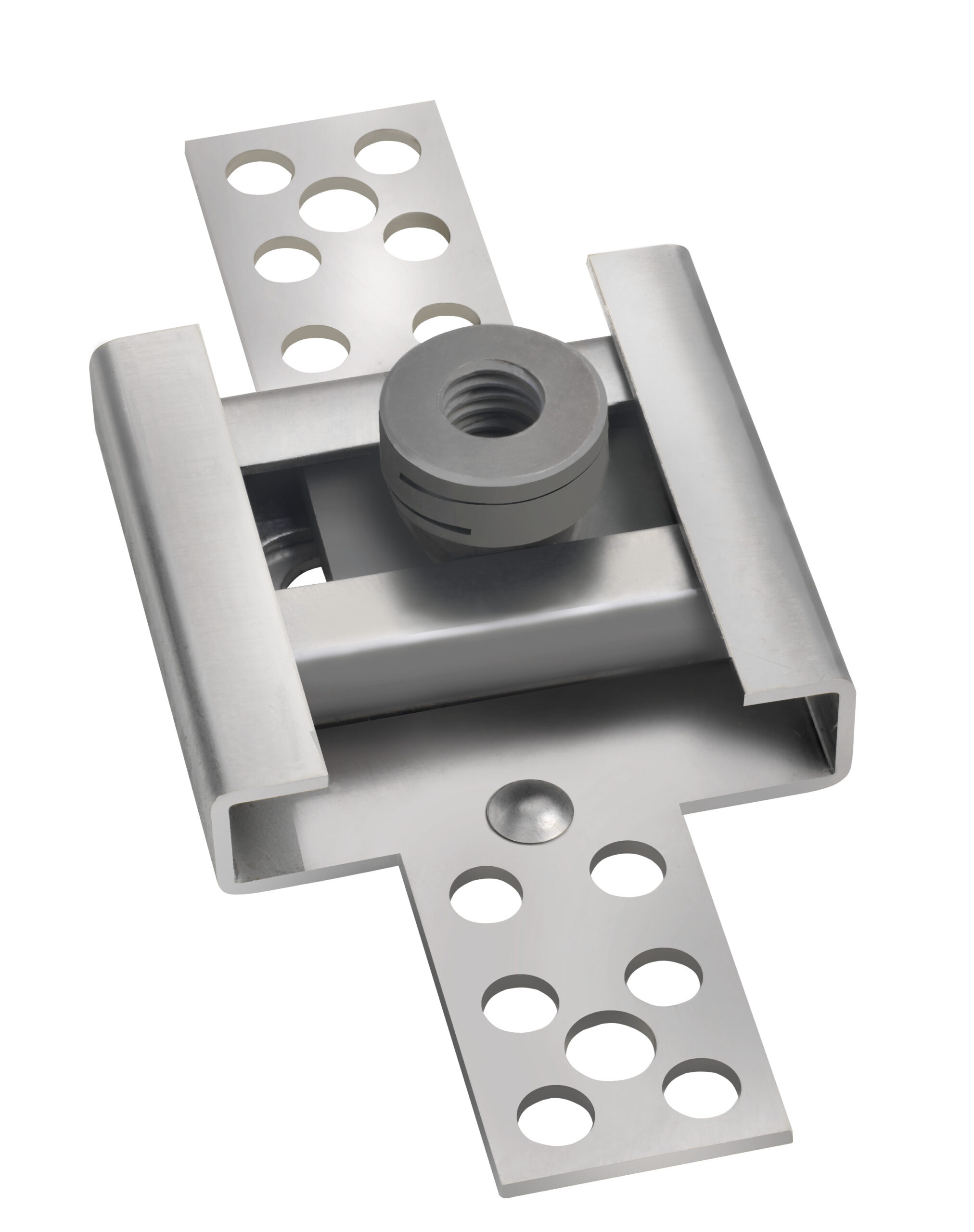

The main innovation lies in the polyvalence of the profiles.

Manufactured from a choice of materials, including stainless steel, aluminium and steel, and designed with our self-locking nuts with double superposed slots, these profiles are available in two configurations:

- Unidirectional movement, which offers a predefined range of movement

- Multidirectional movement, which allows flexibility on a given surface

For applications requiring complex assemblies, such as in the rail, these profiles are ideal for securely fastening composite panels without compromising the structural integrity or precision of the assembly.

J. LANFRANCO multi-directional modular fixtures allow 12mm movement in all directions.

These fasteners adapt to imperfections in the assembly, minimising costly interventions and improving installation and maintenance times.

The use of these systems is particularly advantageous in industries where labour costs are high, as the fasteners can be installed quickly and efficiently using simple riveting techniques, without the need for welding or other labour.

These products can be adapted for each application to meet the specific needs of our customers.

In conclusion, J. LANFRANCO & Cie’s innovative fastening solutions represent a major step forward for industries working with thin materials and composites, offering reliable, adaptable and cost-effective solutions.

This article first appeared in the Railway-News Magazine Issue 1 2025. Download the full PDF version here.