In March 2025, researchers from Holmberg GmbH & Co. KG attended the first joint annual meeting of the German (DAGA) and Danish Acoustic Societies (DAS) in Copenhagen.

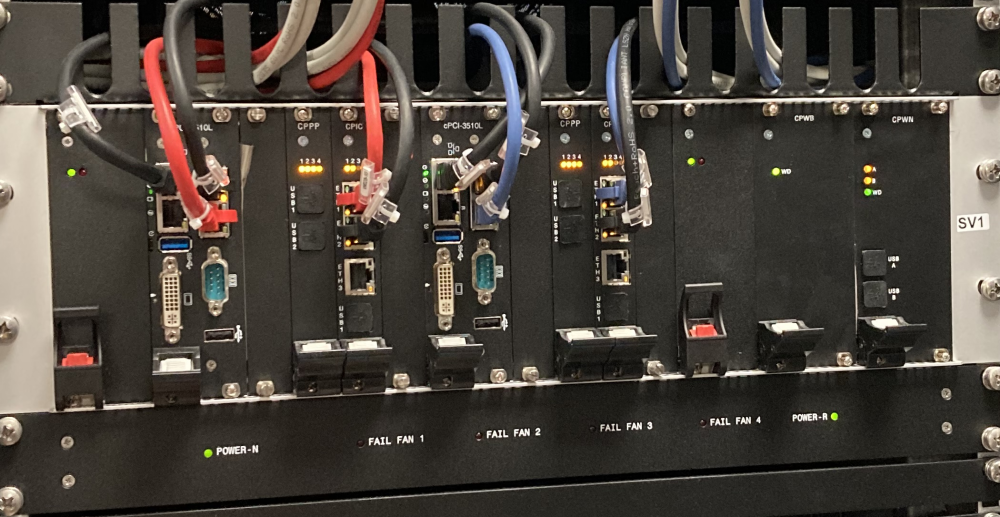

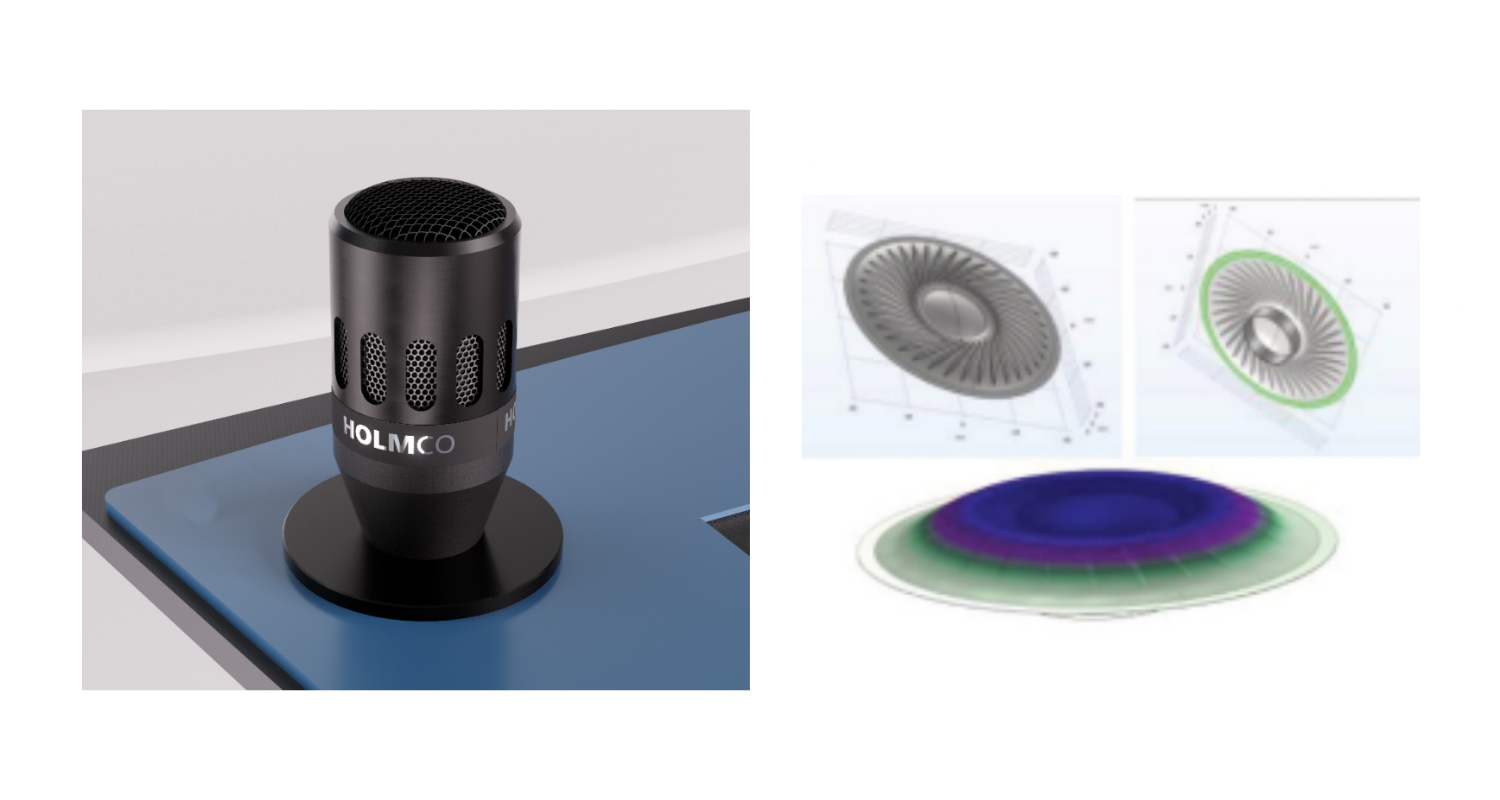

At this international conference, Dr. Wolfgang Weith, a member of Holmberg’s R&D team specializing in acoustics, held a talk. He spoke about the challenges of creating a new high-performance transducer for use in noisy environments such as a train driver’s cab. These transducers are used in robust microphones and handsets. An example of which you can see in figure 1.

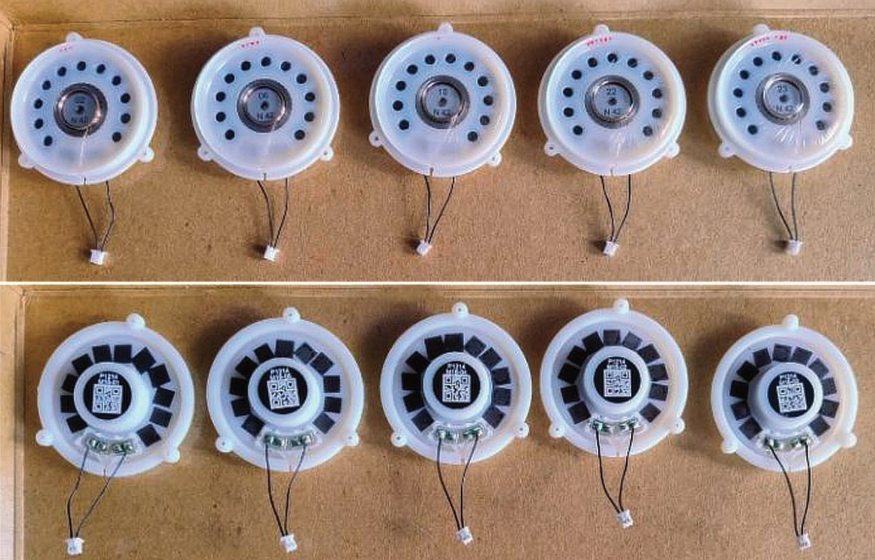

Dr. Weith described how the transducer was developed and made ready for series production in the span of a few months. This was made possible by combining simulations with rapid prototyping via 3D printing. Also, Holmberg is one of the few manufacturers in Europe to combine all development and production steps under one roof. Thanks to this advantage, we can develop our ideas in a fast and coherent process.

The conference proceedings paper titled “Development and production of a high performance microspeaker for ANC headsets suited for voice communication in extremely noisy environment” can be downloaded here.

Holmberg has decades of experience in developing and manufacturing acoustic products for professional use in settings such as aviation, emergency services, military or railways. A hallmark feature of our products is their outstanding speech transmission quality even in challenging acoustic environments.

Our products are designed, developed and manufactured in Germany according to the highest quality standards, as well as according to the environmental standard DIN EN ISO 14001, and the company has been awarded the EcoVadis Bronze Medal.

This article was originally published by Holmberg GmbH & Co. KG.