High-Speed Rail: Why Quality Rail Materials Are Key to Sustainable Travel

- By Patric Scheidner, Corporate Vice President Global Head of Aviation, Space, Rail

It’s time to turn our attention to sustainable travel: high-speed rail. According to the International Energy Association, high-speed rail is a promising, low-emissions substitute to air travel.

To achieve carbon neutrality by 2050, we must look to high-speed rail as a go-to choice for long distance public transport. And to do this, we need to be using quality rail materials.

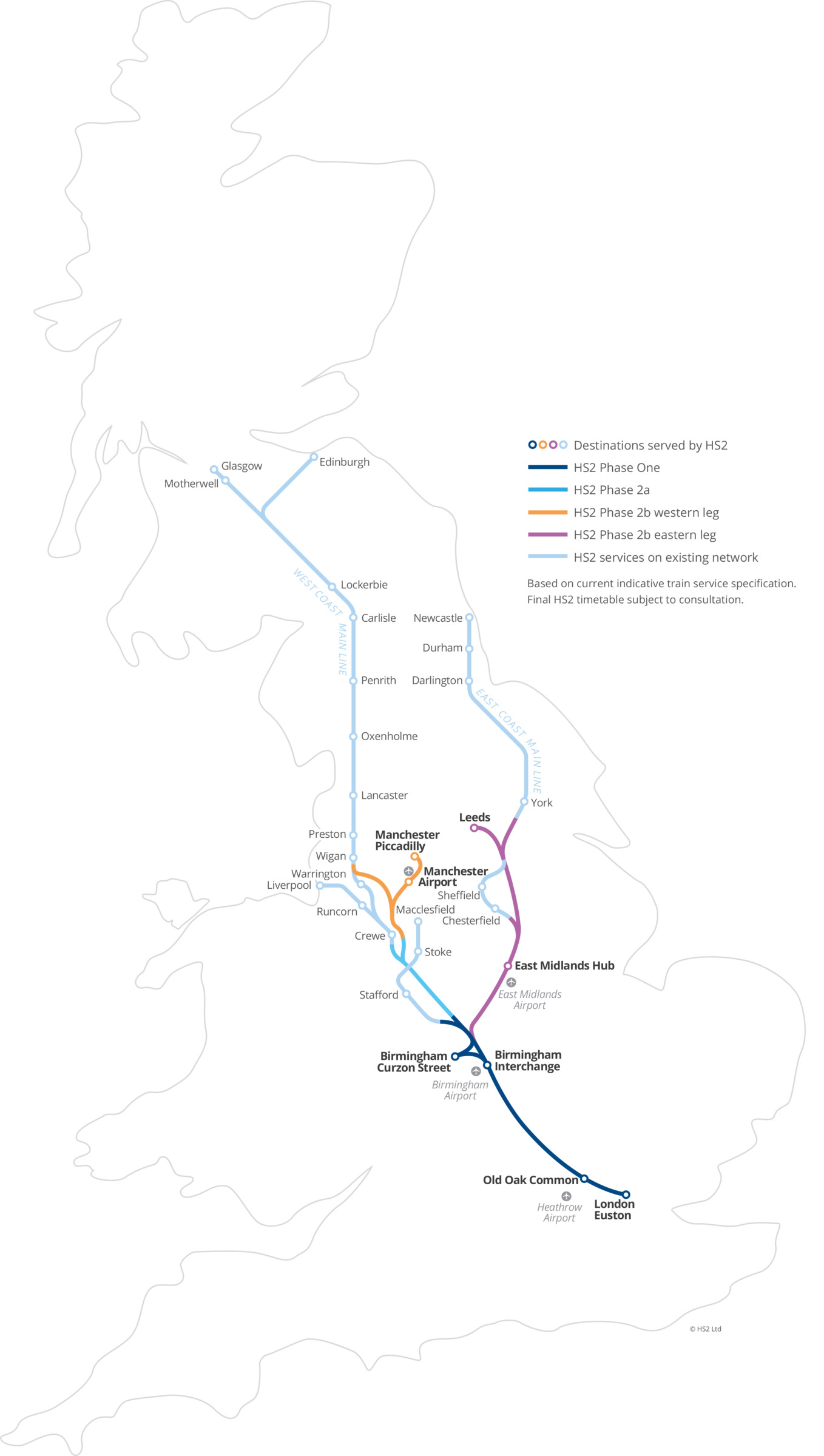

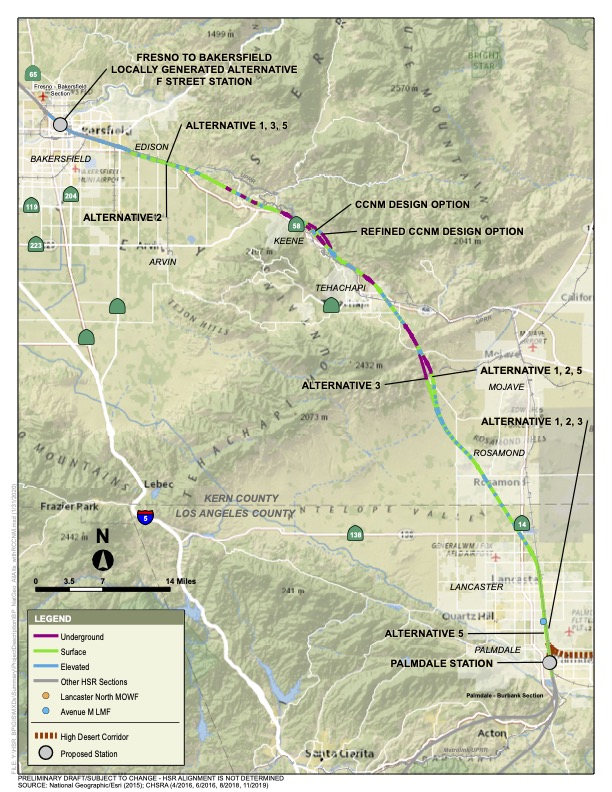

High-speed rail lines have undergone rapid expansion in the past few years. China has invested heavily in high-speed rail lines, with Europe and Japan following close behind. India, too, is in the process of building its first high-speed railway, which will connect Ahmedabad to Mumbai.

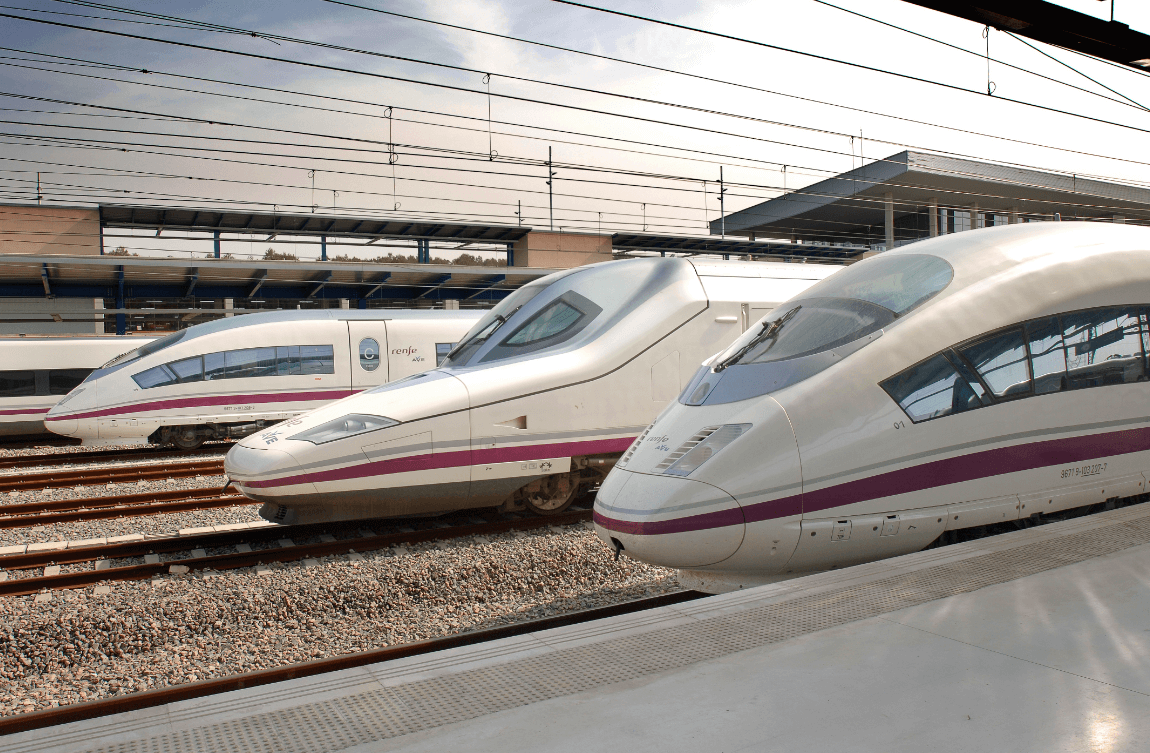

One thing that can increase sustainable train travel is faster travel times between major cities, at zero emissions. Another key factor is comfort, which I’ll explore later in my post. To achieve this, quality rail materials are key.

How Is the High-Speed Rail Industry Advancing?

There are a number of technical innovations within the high-speed rail sector that could make the trains of tomorrow faster, safer and more sustainable. These include better connectivity and heat management.

Add in the use of quality materials (lightweight and recyclable products), plus extra comfort for passengers, and rail transportation could become one of the most sustainable – and popular – transport options available.

How Will High-Speed Rail Be Powered?

Electric Trains

Rail transport is the most electrified transport sector, according to the International Energy Association.

Electrification brings many benefits. For one, electric trains are better for the environment than diesel trains. They are also quieter, improving travel quality for passengers and even the quality of life for those living close to train stations and railway lines.

Yet, they are not perfect. Electrifying a network incurs high overheads, due to the fact that electric trains need overhead power lines – and these need to be installed.

That’s where battery-powered trains come in.

Battery-Powered Trains

Battery powered trains are cleaner and quieter than any other form of rail transport.

In the past, the use of batteries has been limited, because of their weight.

But recent technological developments mean that batteries are getting lighter, making battery-powered trains a clean, zero-emission solution.

How Do Quality Rail Materials Benefit the Consumer?

Passengers want faster, safer trains, and more comfortable journeys. This means reducing noise and carriage vibration to ensure a smooth ride.

Just a single coating of damping materials on the inner rail coach walls can significantly lower noise pollution. Underbody coatings, meanwhile, reduce noise and vibrations, increasing passenger comfort.

Safety here is key. These coating materials need to meet strict fire, smoke and toxicity (FST) requirements.

A quality supplier can provide safe formulations of these coatings. These sustainable coating materials produce fewer toxic gases, and produce a low smoke density. In case of a fire, sustainable coating materials are fire resistant and can actually help stop flames from spreading.

How Can High-Speed Rail Be More Sustainable?

Electric and battery-powered trains are already a ‘clean’ form of public transport.

To further increase this:

- Material suppliers must be highly regulated

- Materials used must be lightweight and recyclable

- Materials should be FST and REACH compliant

How Important Is Thermal Management in Battery and Electric Trains?

With increased speed and power comes increased heat. Efficient use of thermal management systems such as lubrication systems, and engineered thermal and light cure acrylic, can help optimize heat balance.

Advancements and innovations in electric and battery technology are broadening the limits of high-speed rail travel. This, along with increased sustainability, is helping high-speed rail travel become a viable alternative to air travel.

An expert supplier can help provide manufacturers with effective solutions that simplify the manufacturing process, resulting in faster, quieter, and safer trains.

To learn more about innovations in high-speed rail, feel free to contact us.

This article was originally published by Henkel.