As one of the most climate-friendly modes of transportation, the railway plays an important role when it comes to reducing carbon emissions.

Most operators are building on this environmental advantage in order to save CO2 emissions, costs and energy. One of their reliable partners is the specialist for compression technology in refrigeration and air conditioning, BITZER.

In the last few years, railway operators have started several projects to significantly reduce power consumption and CO2 emissions of their vehicles. Besides improvements such as brake energy recuperation, many components of a train can contribute to reduce both energy consumption and emissions.

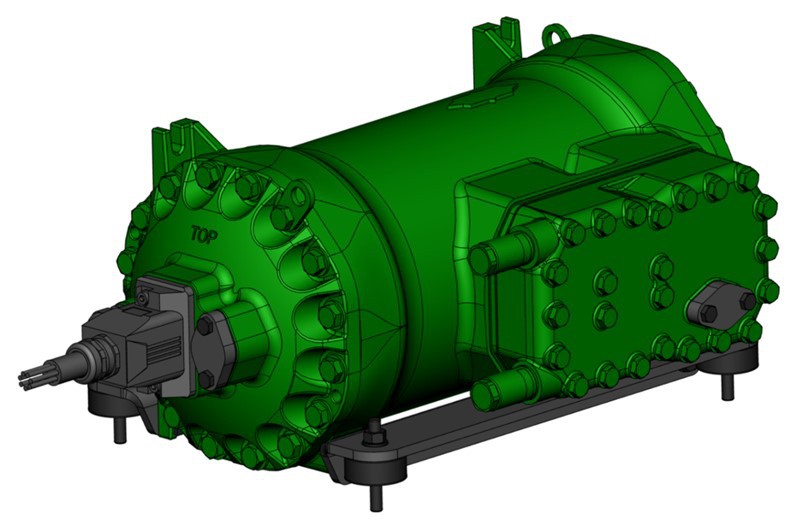

With decades of experience in mobile applications, BITZER manufactures compressors for the most varied air conditioning applications associated with railway. BITZER compressors meet the high demand for climate-friendly solutions for mobile refrigeration and air conditioning applications and prepare users for the challenges of the future.

Cost-Effective and Sustainable

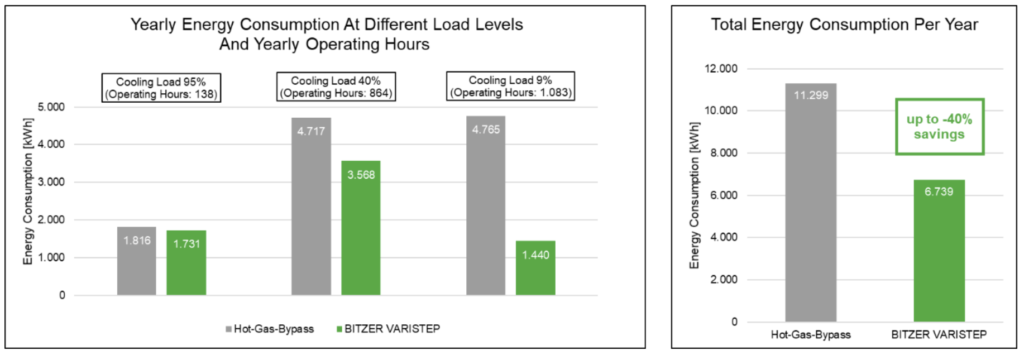

In railway, today’s air conditioning systems are most often equipped with simple installations for capacity control such as hot-gas-bypass, in order to ensure passenger comfort. However, such control systems are at the expense of energy consumption. For both BITZER and railway operators, energy efficiency is a decisive factor, both ecologically and economically. Where costly frequency inverters can’t be used, but the convenience of efficient capacity control is required, BITZER can offer a cost effective alternative with the VARISTEP. VARISTEP is based on the tried-and-tested system of mechanical capacity control and enables the capacity of reciprocating compressors to be adjusted in fine steps under all operating conditions. Its unbeatable benefit: the system offers a virtually stepless capacity control from 10 to 100 per cent, which enables outstanding system efficiency with maximum passenger comfort. The yearly operating costs of railway refrigeration and air conditioning systems can thus be significantly reduced in comparison to conventional hot-gas bypass systems.

Where Does the Energy Saving Come From?

The VARISTEP design is based on blocked suction technology, reduces the refrigerant volume flow of the compressor and consequently lowers the cooling capacity and compressor power consumption together. In addition, adapting the compressor cooling capacity to the system cooling demand results in reduced pressure fluctuations and increased evaporating temperatures. This improves the overall efficiency of the air conditioning system even further.

The following graphs show that seasonal energy savings are substantial. It’s a calculation based on a typical light rail vehicle air conditioning system operated in central Europe. Two identical refrigerant circuits are compared, one with VARISTEP, the other one with a hot gas bypass. Different cooling loads and operating hours over a seasonal year are taken into account. Where part load operation is required frequently, the VARISTEP technology contributes to a decrease in energy consumption of up to 40 per cent for the compressor.

Designed To Be on Track

Also the use of natural and alternative refrigerants contributes to climate friendliness. BITZER develops suitable compressors for almost all common and alternative refrigerants. With its ECOLINE reciprocating compressors, BITZER offers a wide range for the use of natural refrigerants such as hydrocarbons and CO2. Quiet in operation and low in vibration, it is optimised for refrigeration and air conditioning applications and even the VARISTEP is ready for use with natural refrigerants.

Contact:

bitzer.de

[email protected]

This article was originally published by BITZER.