GSF Rail Infra

Ground Displacing Shield Foundation for Catenary, Noise Barrier, and Signal Poles

In recent years, a new system for the foundation of catenary masts, noise barriers, and signals has been developed and used in the Netherlands. This method is characterised by a short construction time and thus considerably reduces the overall construction time for catenary systems. The method is currently being validated for use in Germany.

Introduction

The demand to increase the share of electrified track can only be met with additional electrification of railway lines. Electrification construction is considered time consuming and expensive. One reason for this is the time-consuming foundation procedures for overhead line poles, which are either cast or set on site and/or drilled. All the usual methods require a significant amount of construction time and construction machinery.

This is where the development of the Ground displacing Shield Foundation (GSF) comes in: The main objective is to significantly shorten the construction time for the mast foundation and thus reduce the overall construction time for overhead lines.

Technology

The core of the GSF method is an earth displacing foundation body with an integrated top plate. This is driven into the ground directly at the mast site with a hydraulically operated vibration unit at a frequency above the natural frequency of the ground.

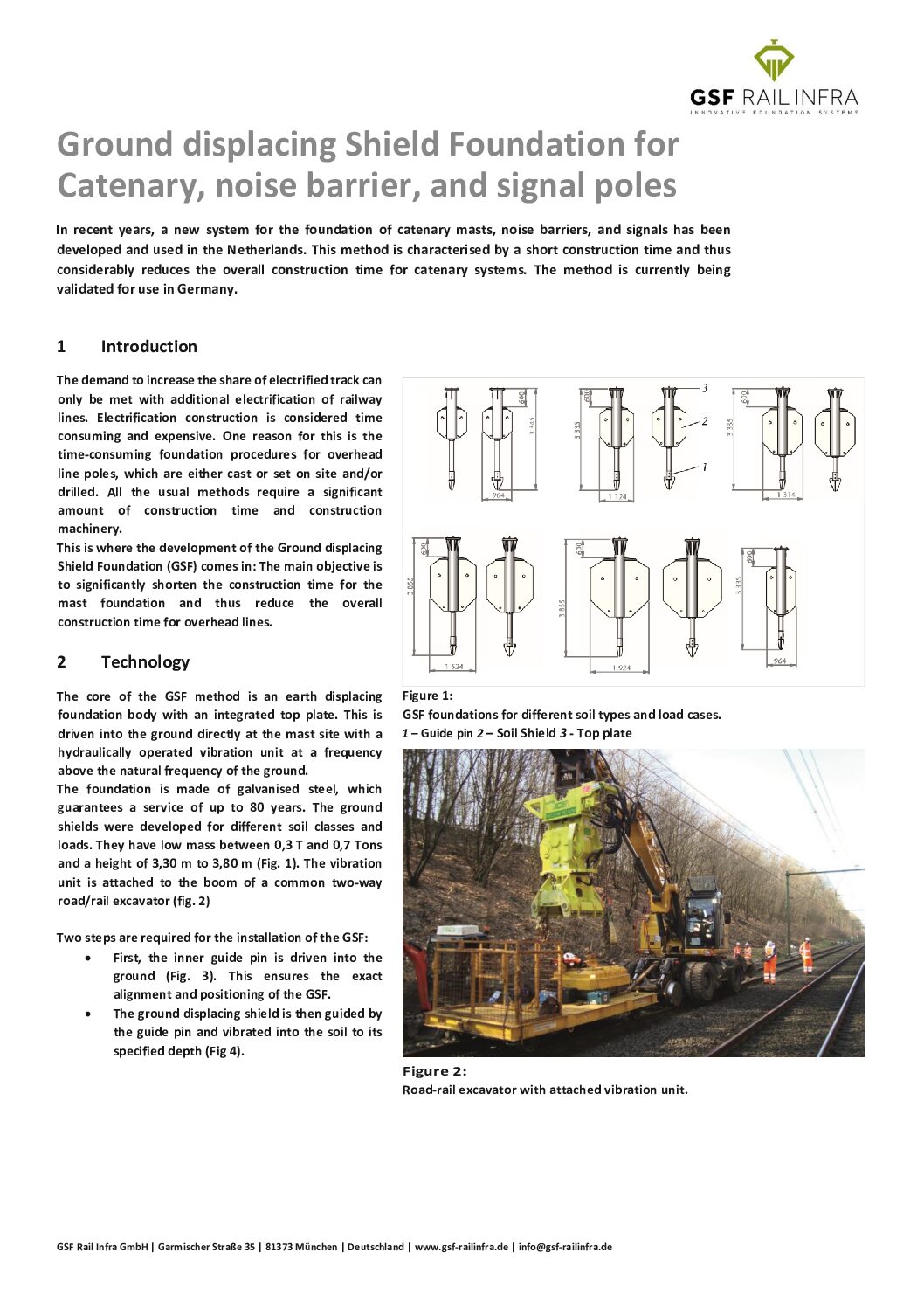

The foundation is made of galvanised steel, which guarantees a service of up to 80 years. The ground shields were developed for different soil classes and loads. They have low mass between 0,3 T and 0,7 Tons and a height of 3,30 m to 3,80 m (Fig. 1). The vibration unit is attached to the boom of a common two-way road/rail excavator (fig. 2).

Two steps are required for the installation of the GSF:

- First, the inner guide pin is driven into the ground (Fig. 3). This ensures the exact alignment and positioning of the GSF.

- The ground displacing shield is then guided by the guide pin and vibrated into the soil to its specified depth (Fig 4).