Smart Pantograph-Catenary Monitoring Systems for Railway Operators

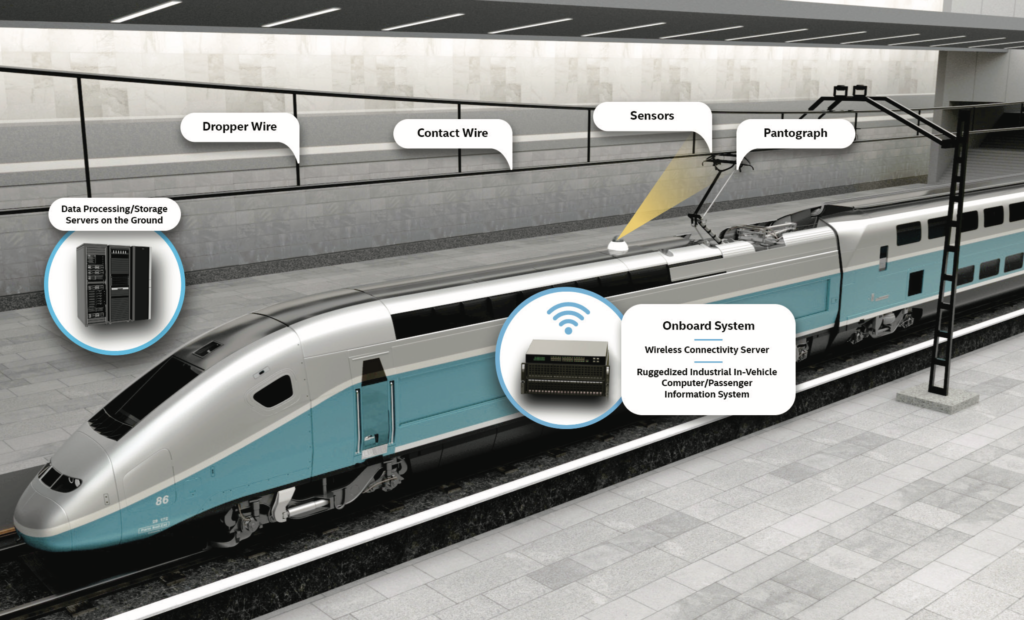

Intel and its global ecosystem of partners have collaborated on a Pantograph Catenary Monitoring System (PCMS) solution. This fully automated pantograph inspection system for predictive maintenance offers advanced accuracy and measurement technology for helping to detect damaged pantographs and catenaries. Using a combination of 3D laser triangulation, Artificial Intelligence (AI), Machine Learning (ML), and advanced software algorithm processing at network edges, the system helps accurately detect and measure pantographs for damage. The system can then alert rail operators to schedule maintenance.

This Intel-based system helps decrease unscheduled maintenance and increases rail fleet availability. PCMS identifies pantograph damage, such as deformed bows, damaged graphite plates, cracks and missing parts. The system also identifies abnormalities to catenary components like arcing and broken or loose dropper wires. Finally, PCMS identifies potential risks caused by foreign objects, such as bird or animal nests and other unwanted things.

How the Pantograph-Catenary Monitoring System Works

PCMS systems are activated when a moving train activates a light beam from either a train-mounted or wayside system. Once started, the system takes precise train speed and direction measurement before automatically detecting and identifying the components for a specific railcar. A co-located LED array illuminates the pantograph head as it passes through a defined area and a set of sensors, typically 3D cameras capture stereoscopic L/R images of the pantograph and store it in a database for analysis. The system retrieves the captured images, and uses advanced Intel-based image processing technologies analyse each image before generating a report. Rail operators automatically receive notifications when a damaged pantograph, catenary, or foreign objects are detected. The detection of damaged parts triggers a notification containing the exact train route and location data.

Additional benefits include:

- Maximised fleet availability with fewer unexpected maintenance costs

- Minimised safety risks to maintenance staff, with reduced need to access the top of rail carriage or power car

- Enhanced access to consistent data from fully-automated pantograph inspections

- Reduced risk of line teardown and other power line maintenance

PCMS is flexible and designed for deployments across two railway operator scenarios:

- Train-mounted pantograph monitoring system

- Wayside pantograph monitoring system

Find out more about Intel’s PCMS.