The harsh Australian sun can weather and deteriorate a wide range of objects and products – with rubber included under this umbrella.

The ultraviolet (UV) radiation can have a drastic effect on rubber without intervention and synthetic additives. Looking at natural rubber (NR), let’s dive into the effects UV radiation can impose.

Natural Rubber (NR) vs UV Radiation

With great elasticity, tensile strength and resilience, NR is a fantastic product that is commonly utilised for:

- Tires

- Tubing

- Belts

- Hoses

- Shock mounts

- Electrical components

- Drive wheels

However, despite the excellent mechanical and wear properties of NR, it has minimal tolerance to UV radiation. Infiltrating the rubber on a molecular level, this radiation weakens and breaks the monomer chains that form the organic polymers – hindering the polymerization process. The effects of this can facilitate some detrimental consequences, including:

- A loss of elasticity and flexibility – exposure to UV radiation is a sure-fire way to eliminate the usefulness of this material. In destroying the monomer chains, the properties that make NR so favourable are removed.

- A loss of mass – an IOP Science study highlighted the correlation between UV exposure and weight reduction when dealing with varying rubbers. The study subjected varying rubber materials to two separate conditions of extreme heat – including UV weathering aging and being placed within an oven. Recording the effect on weight periodically across two weeks, NR experienced significant shrinkage in both environments.

- The forming of cracks – this is commonly found when UV radiation meets a stretched rubber surface. While in some cases this isn’t an instant death sentence for your product, it does have the potential to be.

Additionally, other common effects UV radiation can emit on NR can vary between cosmetic and structural, including:

- Disintegration

- Loss of strength

- Colour fading

- Producing a chalky surface

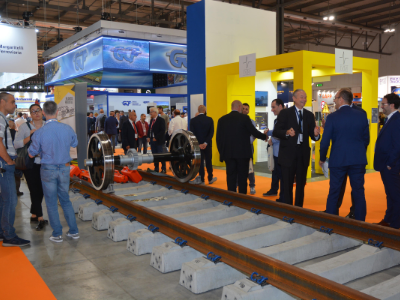

Our window seals and door nosings installed on rail rolling stock are subjected to some of the harshest UV environments. For these environments, in order to overcome these potential effects of UV, we developed a synthetic EPDM compound that provides a long-life solution and conforms to international standards for fire resistance and smoke toxicity.

Read more: Railway rolling stock

Where Prevention and Sustainability Meet

Rubber is a fundamental material used in a broad range of both industries and applications – because of the superior benefits it provides. As a rubber manufacturer, we acknowledge that our materials and our products have an impact on the environment. Our influence is vast, operating across multiple industries including:

Therefore, we’ve embarked on a program to mitigate and offset the effects of our products. The aim is to ensure that our products are manufactured and utilised in the most sustainable way – we achieve this via a few means:

The Right Rubber for the Right Environment

We’ve accumulated more than 50 years’ experience in this industry and as such we have a profound ability to create exact compounds. We’re currently established to provide precise analysis and execution to situations surrounding extruded, moulded, and hand-built Industrial Rubber Products. Therefore, catering to highly demanding applications, found in extreme weather conditions, has become a specialty.

Read more: Case Study – Ballast Tools

Compound Designs

A good rubber compounder knows there’s more to the design than just the science of it. We understand that the development of our compounds should be done utilising the best qualities for your unique situation – while also offering a cost-effective solution.

Our range of compounds are broad, including fire retardant compounds compliant to the International Standards – including DIN, NFF, and more. We steer clear of a one size fits all approach and consequently we offer a customised solution based on your requirements.

Similarly, we are committed to research and development, continuously developing new materials and improving existing compounds to ensure we always put forth the best options to our clients.

Our Move to a More Sustainable Business

A sustainable business is a paramount focus for us. As a result, we dedicate effort and action across our business to help facilitate this – including:

- Product designs

- Work environment

- Business practices

Through raising awareness and progressive initiatives, we encourage our employees to share their ideas for advancing sustainable development in the workplace and beyond.

To learn more about how we can tailor an innovative and unique solution to your circumstance, please contact us.

This article was originally published by Derby Rubber.