With almost limitless potential, the creation of the ideal fabric for your rail interior can be a daunting, if exciting, task. From choosing the perfect shade and establishing an on-brand pattern to navigating global flammability standards, there is a myriad of considerations to take into account – and it can be difficult to know exactly where to start.

In this article, Aimee Larson, Senior Designer at Camira – the UK’s leading manufacturer of transport textiles – explains everything you need to know about creating the perfect fabric for your railway.

First Things First, Construction

To begin, I always recommend identifying the aesthetic you’d like to achieve, and the priority of your key concerns – are you looking for a traditional or contemporary interior? A sleek or textured finish? Is practicality at the top of your list? Once you’ve established the answers to these questions, you’ll be in a much better position to begin identifying which construction is the best fit for your needs.

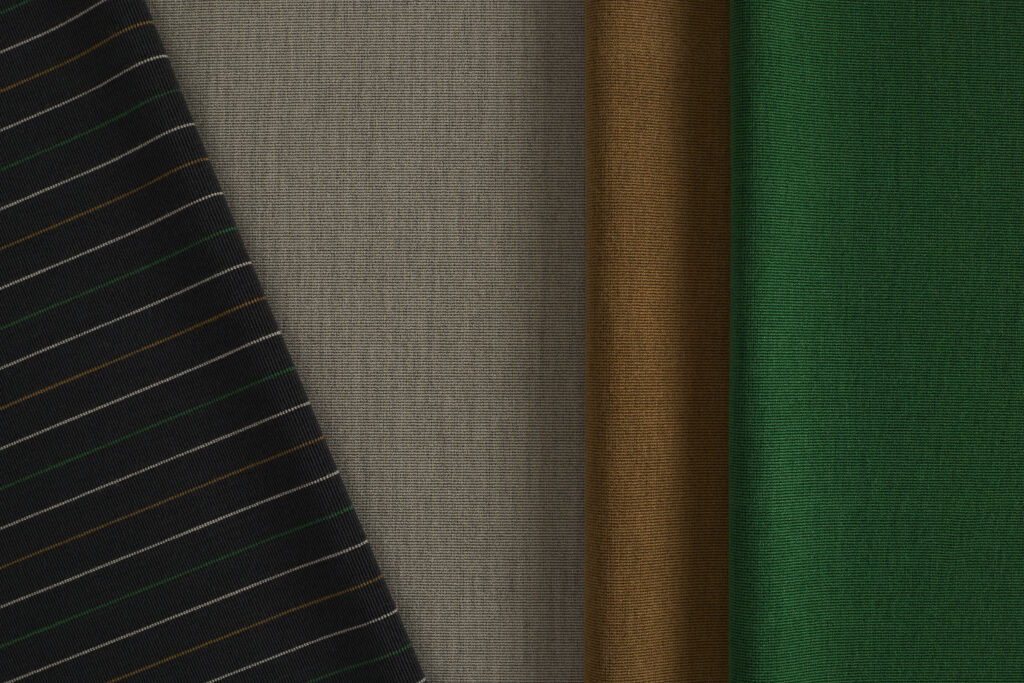

In short, there are four types of construction from which to choose your railway’s upholstery, and these can be summarised as follows:

- Plush: In plush fabrics, the yarn threads stand upright from the ground structure of the fabric, with the individual ends cut at an even height to create a completely levelled surface finish. Highly effective at dispelling dust, plush fabrics offer the ultimate in practicality, and are a timeless, ultra-comfortable, upholstery choice

- Wire woven: Taking their name from the metal wires which are inserted during the weaving process between the raised pile threads and the fabric ground to form loops of pile above the foundation, wire-woven fabrics are perfect for interiors which want a sleek look, without compromising on durability. Also available in Hybrid, an innovative wire-woven fabric construction unique to Camira, the double density all loop face is designed to withstand the demands of today’s transport world, making it a robust yet stylish option.

- Flat woven: Characterised by their flat, two-dimensional surface, flat-woven textiles are created by interlacing warp and weft yarns which construct a fabric where the yarns lie flat rather than upright. A contemporary choice, flat woven fabrics provide a sleek aesthetic, in keeping with the automotive trend.

- Leather: An alternative upholstery option, pure leather, such as our Elite range, provides the ultimate in luxury and can be used alone or in combination with woven fabrics to create accent areas on side panels, bolsters, headrests or piping.

Now, Let’s Talk Colour

Many railways opt for their upholstery to be designed in their brand colourways – whether as a piped accent to a base neutral, integrated into a woven pattern, or embroidered as a logo – there are a number of different approaches. At Camira, we specialise in custom-made fabrics, working in close collaboration with specialist design houses to turn their design concepts into woven realities; from developing exact colour matches to creating perfect pattern repeats, our in-house design studio has the expertise to translate ideas into reality.

In terms of general colour advice, we always recommend avoiding pale shades, such as pastels or taupes, on seating upholstery – simply due to their susceptibility to staining and scuffing – and instead using them as delicate accents on trims, e.g. curtain tiebacks or piping. There’s a reason that so many railway interiors opt for darker shades or vibrant tones – they really do hide a multitude of sins, and with intelligent, considered pattern designs, there is no limit to the visual detail they can offer.

Iconic Designs

Associated with many high-profile contracts where the fabric has become instantly recognisable as an iconic part of the branded interior – think London Underground, the Orient Express, Thameslink, First Great Western, Belgian Rail, Swiss Rail and Queensland Rail to name but a few – our design team has a proven record of developing textiles for rail interiors that are not only on brand, but visually striking – and manufactured to withstand the most demanding of performance requirements.

Bespoke Concepts vs Standard Ranges

The vast majority of railways opt for a bespoke textile, however for those requiring an expedited turnaround, or those who would like a pre-designed quality, there are a number of ways in which this can be accommodated. For example, at Camira, we offer an extensive range of standard patterns which are available to be custom-coloured to perfectly match a branded interior – providing a bespoke look within a reduced timeframe – or which can be ordered ‘off-the-shelf’, manufactured, treated to specific FR standards, and delivered with exceptional ease and speed.

Understanding Flammability Regulations

Formulated in 1987 on behalf of British Rail, the BR252 flammability standard formalised the testing of rail carriage interior fabrics in terms of physical performance as well as their flammability properties. There are now a number of international fire tests and, to provide complete peace of mind, all Camira rail fabrics can be treated to the following geographic standards:

Britain

- BS 6853: 1999: The code of practice for fire precautions in the design and construction of passenger-carrying trains based on the fabric’s location in the train.

Europe

- NF F 16-101: A French standard, this test analyses fire behaviour of material regarding its reaction to fire, opacity of smoke and toxicity of gases emitted.

- DIN 5510: Part 2: A German standard, this test defines the parameters of combustibility, smoke development, dripping and toxicity.

- EN 45545-2 Railway Applications: The European railway standard for fire safety, this test defines the requirements for components dependent on end use and hazard category applied to the vehicle. Key parameters that are measured include flame spread, ignitability, heat release, smoke opacity and toxicity.

Rest of World

- UIC 564-2: App 5: A standard set by the International Union of Railways, this test method determines the fire-resistance of coated and uncoated textiles. The test measures the size of the damaged area and release of burning particles after a flame has been applied.

- AS 1530: An Australian standard providing methods for determining the performance of external construction elements when exposed to radiant heat, burning embers and burning debris.

- GOST 12.1.044.89: A standard applicable to Russia, Belarus and Kazakhstan, this occupational safety standards system measures flame spread, smoke density and toxicity. An environmental test is also included.

- NFPA 130 Standard for Fixed Guideway Transit and Passenger Railway Systems: This standard is predominately used in North America and involves the use of FAR 25.853 (vertical flame test) and ASTM E 662 (smoke opacity test).

If you’d like to speak with our team of experts to learn more about creating the ideal textile for your rail interior, get in touch at [email protected].