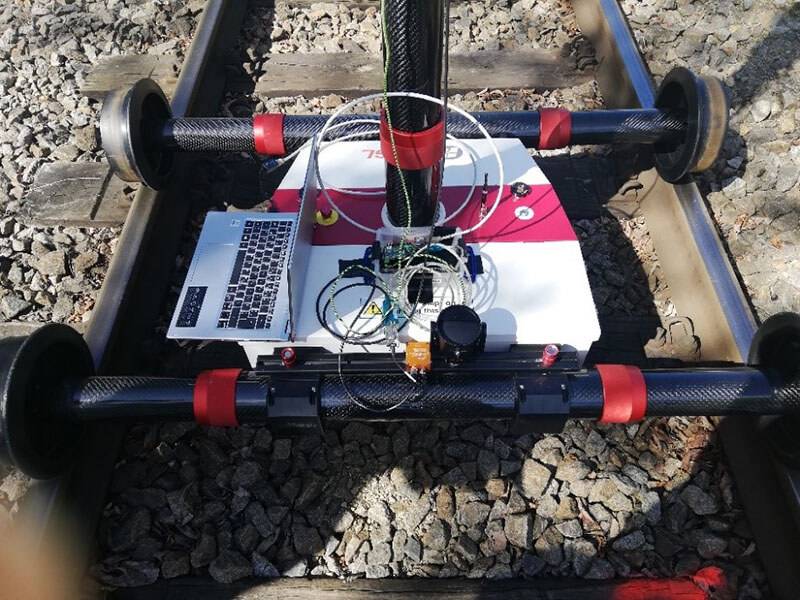

ASC’s RAIL sensor series provides robust, flexible high-precision inertial sensor technologies. Tailored solutions support rail manufacturers and operators in improving the safety, capacity and overall productivity of their rolling stock.

Expanded ASC RAIL Series Meets EN 50155 Standards

Renate Bay, CEO at ASC Sensors, says:Through the rigorous testing and documentation of our dedicated RAIL sensor series’ performance, we’re making it significantly easier for operators to configure and implement individual sensor solutions on their trains.

They can rely on a proven set of stable precision sensors ready for installation, which meet all applicable norms and significantly reduce individual documentation requirements on the part of the operator.

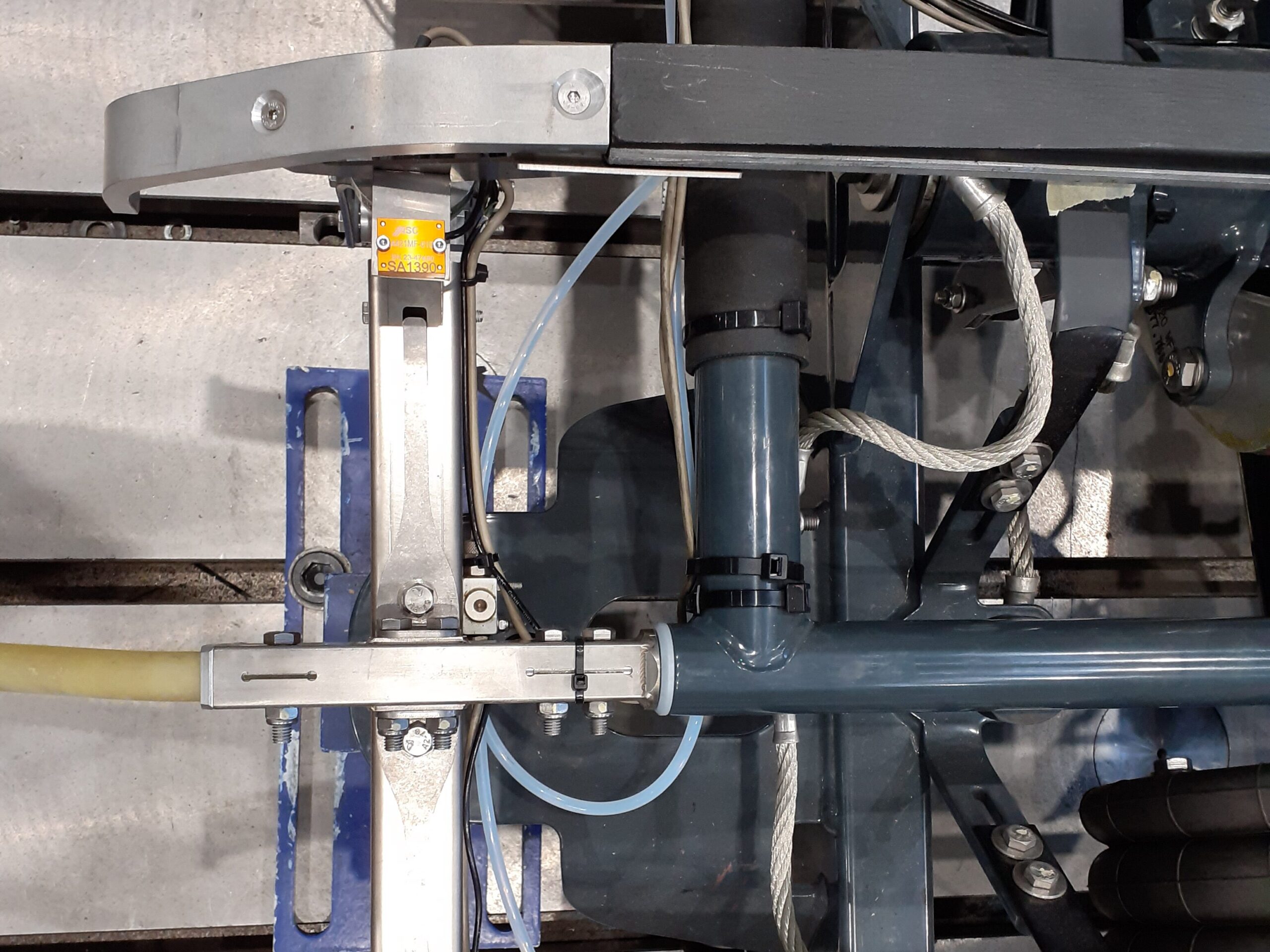

Pre-qualified accelerometers of type ASC RAIL-x152LN have already been in use around the globe. In June, 2024, the RAIL series got expanded with an additional accelerometer model ASC RAIL-x151LN, featuring a more compact housing to be able to fit into smaller spaces. The same small housing is used for the new ASC RAIL-27×1 gyroscopes. For all three models, comprehensive evaluations by an independent testing lab resulted in clear outcomes for ASC’s reliable, accurate RAIL series.

The following tests have been performed according to railway standard EN 50155:2021 to confirm climatic resistance and dynamic-mechanical robustness:

- Low temperature storage test – test A

- Low temperature start-up test – test A (OT6)

- Dry heat test – test B (OT6)

- Damp heat, cyclic – test Db

- Insulation tests (before and after damp heat, cyclic)

- Vibration, broad-band random – long time test Fh (category 3: axle mounted)

- Vibration, broad-band random – functional test Fh (category 3: axle mounted)

- Shock testing – test Ea (category 3: axle mounted)

Ready Solutions for Stable Long-Term Performance

Further, interference emission and interference immunity tests were conducted according to standard EN 50121-3-2:2016+A1:2019, confirming electromagnetic compatibility:

- Conducted continuous disturbance at battery port

- Radiated disturbance, electrical field

- Immunity radiated electromagnetic fields

- Conducted immunity, injected currents

- EFT / Burst

- Electrostatic discharge test / ESD

In addition, all components of the ASC RAIL series meet the latest fire protection standards including EN 45545 for electronic equipment on rolling stock. This includes a robust, non-flammable, laser-welded stainless-steel IP68 housing as well as rail-certified cables and cable glands. Jointly with their built-in technologies this leads to a reliable sensor ecosystem to withstand the hardest shocks, vibrations, temperatures and other adverse conditions typically encountered in rail applications. Even under the harshest conditions, this ensures optimal performance and stable long-term operation.

Compact Yet Powerful Capacitive Accelerometers and Gyroscopes

The standard accelerometers ASC RAIL-x152LN are available in uniaxial, biaxial and triaxial configuration. The newly developed, more compact housing option is used for uniaxial and biaxial accelerometers ASC RAIL-x151LN.

Both accelerometer models are based on proven MEMS technology and capacitive operating principle. This technology enables the measurement of static (DC) and constant accelerations, which can be used to calculate the velocity and displacement of moving objects. Depending on the design of the spring-mass-damping system, however, it is also capable of detecting dynamic (AC) accelerations of amplitudes from ±2 g up to ±400 g and within a maximum frequency response range of up to 1 kHz (±5 %). The integrated electronic circuits enable differential analog voltage output (±4 V FSO) and outstanding noise performance from 7 to 400 μg/√Hz.

The ASC RAIL-27×1 gyroscopes are based on established MEMS vibrating ring sensor elements. The design of the micro-mechanical silicon structures makes these gyroscopes extremely insensitive to external impacts and vibrations. Their integrated electronic circuitry enables a single-ended, analog voltage output (0.66 to 2.64 V FSO). These uniaxial, biaxial or triaxial gyroscopes are available in four measurement ranges (75 °/s to 900 °/s), featuring a bias stability of 12 °/hr and an angular random walk of 0.2 °/√hr.

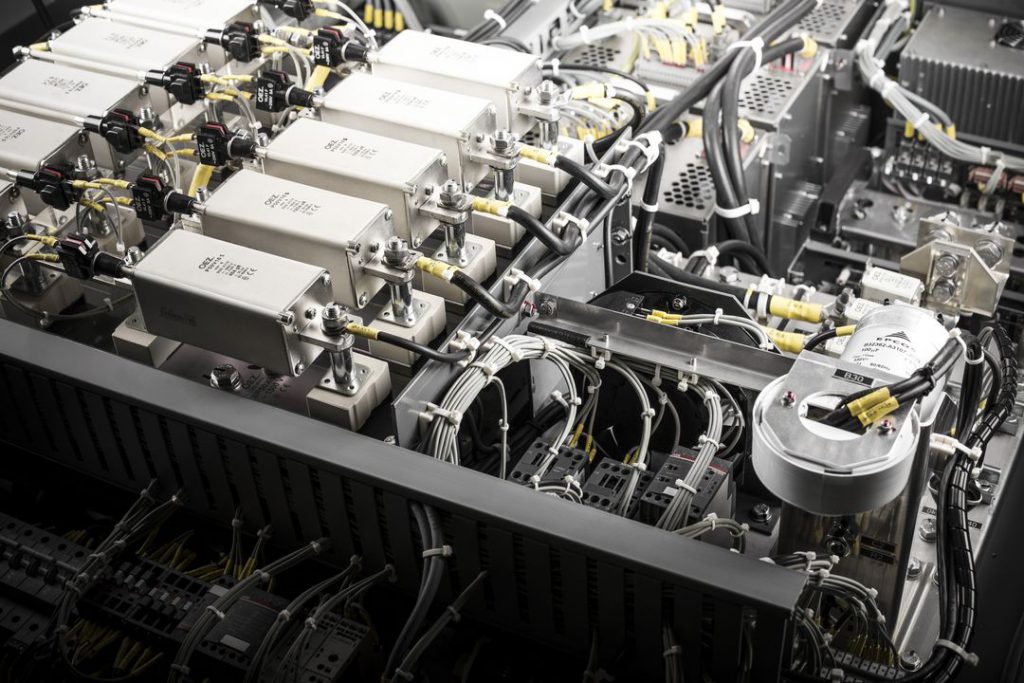

Convenience for Rail Operators

In addition, ASC has started configuring special editions of this same series of dedicated RAIL sensor applications. By combining accelerometer and gyroscope sensor elements, an integrated sensor system featuring up to three degrees of freedom with individually adjustable measurement ranges can be achieved. Considering all possible variations, this leads to the most flexible precision sensor toolbox for railway operators. This comprehensive solution is available to accurately capture, evaluate and manage all relevant factors required by individual customers, in a small, highly robust inertial sensor box.

Markus Nowack, Application Engineer at ASC Sensors, concludes:In essence, rail operators can now mix and match from ASC’s ready RAIL series components to build customized sensor solutions meeting their unique needs.

Choosing from a proven set of inertial sensors meeting applicable national and international standards will significantly facilitate tailored solutions, saving time and budget while strengthening the safety, capacity and productivity of the world’s railway systems.

This article was originally published by ASC Sensors.