The AeroLiner3000 – A Fully Compatible Double Decker Train for Great Britain

By Zoe Cunningham and Josephine Cordero Sapién

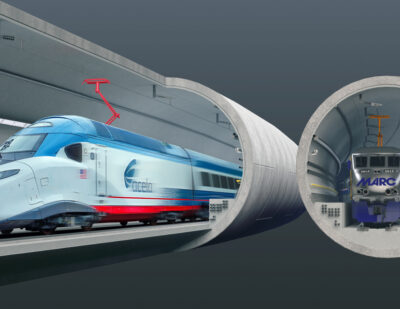

The AeroLiner3000 is a fully compatible double decker train for Great Britain, first unveiled at InnoTrans 2016. The UK Department for Transport has shown an interest in the AeroLiner3000 and negotiations are on-going.

With capacity a major challenge for UK railways, designing double decker trains already in use on the continent for the UK network is an innovative solution to a problem not easily solved. Space restrictions mean trains can’t be made taller or wider, but nor can they be made longer and longer, because of platform lengths. We wanted to hear more about this solution put forward by Andreas Vogler Studios.

In addition, we have chosen to feature the contributions made to the project by two suppliers to the railway interiors market, Lantal Textiles and Forbo Flooring, as part of our focus on railway interiors in our latest eMagazine.

Railway-News: Mister Vogler, can you tell us a bit about how you approached the problem of overcrowding on trains? Where did you initially see opportunities for design to alleviate the problem? And what were the design constraints?

Andreas Vogler: Britain has greatly invented the railways in the 19th century, but is also trapped in its historic infrastructure, which grew very fast by many private companies, who made the tunnels as small as possible to cut costs. It is the cost of liberal capitalism that often a greater vision is missing. But that was 150 years ago.

However, British rail is a story of success with growing passenger numbers since the 1990s. British train operators so far have been catching this capacity growth with seat pitches reaching their ergonomic limits and with peak-hour travel being very expensive. However, passenger numbers keep on growing, because also the roads and the sky are full in Britain. It is a country on the move.

On the continent, the capacity growth has been caught by double decker trains, which increase a train’s capacity by up to 50% without a change in infrastructure. On the continent the loading gauge historically is large enough to allow that; in the UK it’s not.

When the Rail Safety and Standards Board RSSB with its Future Railway Programme launched the competition of a future train in Britain, we wanted to take up the challenge.

The very tight infrastructure in UK is a major constraint in our design. Already 10cm more in each direction would bring great benefits for the design. In the short term, the train we are designing could bring a relevant seating capacity increase without affecting the infrastructure at all, in the long term, we hope it starts a discussion on how UK can create an rail infrastructure for the 3rd millennium. DLR (German Aerospace Center) has already developed some radical but consequent ideas in this direction.

RN: What stage are you in the development of the AeroLiner 3000 prototype? We hear you’re hoping to build a prototype next year.

AV: After a feasibility study we did complete a demonstrator study, where we designed and built half a coach as a full-scale demonstrator, which was showcased at the world’s largest railway trade fair, InnoTrans, in September 2016 in Berlin, Germany.

At the moment we are trying to form alliances to further promote the train. We are talking to various authorities and manufacturers to invest into a future train concept, which has not only benefits for the UK, but through its advanced technology can also save considerable running costs on standard gauges all over the world.

RN: What’s unique about the challenges in the United Kingdom’s railway system from other systems in Europe?

AV: As mentioned above the British loading gauge is below 4m for the majority of the lines, whereas the main lines on the continent are at around 4.5m. Also the platform level in UK is 915mm, whereas the European Union Technical Specifications for Interoperability TSI target is for 760 and 550mm, especially to accommodate double decker trains. This creates ergonomic challenges when increasing capacity. Also many railway stations are not really prepared for a capacity increase. You also need to think how to get people on and off a train. The train is a system which you always need to considerate holistically.

RN: Do you hope your prototype for the UK could be applied elsewhere?

AV: Other countries in the world also have low tunnels (as for example in downtown Sydney). In addition, we could conceive of double decker underground trains in mega cities. A train with a lower profile also has a lower aerodynamic resistance, which saves energy and CO2 emissions.

But the major highlights about the AeroLiner3000 are not only its lower profile; even build in a standard profile it will reduce weight and energy use as well as wear on wheels and tracks, which brings considerable cost reductions. Beyond that it also brings a new modern design approach: an airline-style train should attract other operators worldwide.

RN: Aging infrastructure is a challenge in cities and countries all around the world. Generally speaking, how can they start to think about future-proofing their railway systems?

AV: The invention of the train was the entrance into mass transportation 200 years ago. It was the major means of travel for the rich and the poor before the invention of cars and aeroplanes. And astonishingly still today is one of the most competitive means of travel in terms of safety and pollution. Especially in Europe the developing high-speed network starts to make many airline connections redundant.

But there is still a lot of small-scale historical thinking in the train world. A larger vision of the style and noblesse that train travel had in Victorian times is missing in the UK, but also on the continent. We need to work on that larger vision. Why should Google, Apple and others build automatic cars which form little ‘trains’ on the motorways, all with a lot of loss powered by individual engines running at 80mph, when you could make them automatically drive on a car carrying train calling a major cities with a speed of 225 mph? Los Angeles – New York in your own (electric) car in 12 hours, while working, dining and charging the batteries of you car. Future trains could even have individually powered high-speed coaches, running independently and on demand, forming trains on the fly and decoupling at high-speed to serve remote locations on demand. Watch out Google and Apple, trains could be the means of travel in the future, if the vision is right. The technology is already in the present.

RN: Can you tell me a bit about how you arrived at the four Cs of the design brief: capacity, low-carbon emissions through lightweight construction, customer comfort, and cost-sensitive innovation. Is this a strategy that other governments should adopt when thinking about modernising infrastructure? Could you explain how your design addresses each of these attributes?

AV: The 4Cs have been adopted and aligned from central government policy and are common to most transport systems particularly aerospace and automotive. We have been expanding the diagram of the four Cs by additional orbits, which all interlock. If you make your coach lighter by clever engineering and you can fit more people you save energy and carbon emission, but also costs while you increase capacity. Initial costs of the train maybe higher, but savings start as soon as it is running. The challenge is to increase also passenger comfort; that why we also have psychology in our diagram orbit. A lot of the misery of today’s train travel, not only in the UK, is poor communication, poor psychology to make passengers happy and poor passenger flow. We are working on a conceptual level on those fields as well. We should not forget, the passenger is the most important element in the system.

RN: Anything else you’d like to add?

AV: Andreas Vogler Studio has experience in the design of small spaces. Working in aerospace design and doing practical research in British architect Richard Horden’s Micro Architecture Study Group at Technical University in Munich, we were confident to design a double decker high-speed train for the very tight British loading gauge. It is changing some paradigms of a train, it is more like a Learjet on rails.

RN: Which major aspects of the design and research that you have been doing in the aerospace field for years now did you apply to the design of this train? Which major aspects of the engineering are “revolutionary” in this context?

AV: I think this is difficult to highlight with a concrete example, it has more to do with a state of mind and design methodology. For me it was always crucial to work in a trans-disciplinary manner and not be trapped inside the disciplines and inside the specific industries, which all have their mentalities and home-grown limitations.

In aerospace design one is developing a high awareness of the safety and engineering implications each design decision may have or not. As a designer you get very sensitised to lightweight construction, energy consumption and high passenger comfort in very small spaces. Whereas many in the train world may think a double decker on a low profile is not possible, for us with our background it was clear from the beginning that we can create high business jet-like comfort in a restricted volume, which people will also perceive as comfortable.

The same should be said for the engineers of DLR (German Aerospace Center). Although the department we worked with is specialised in high-speed trains, they have the whole background of aerospace engineering, which influenced their thinking about light construction, mechatronics, aerodynamics and so on.

RN: What is “interactive” about the train’s controls?

AV: We are planning the possibility for the passenger to interact with the environment by an app. The passenger can control light, the shading of the electronic windows individually. But also each passenger could tell the app if he/she feels too cold or hot. The smart system would give the passenger feedback of what the average temperature wished by all passengers would be. It is a kind of crowd sourcing environment. On a psychological level the system would give the passenger the feeling of having control over the environment, to give feedback. Furthermore, it would bring in a social component and balance the individual feelings.

RN: Which particular principles of airline design did you apply to the interiors of this train to create optimal comfort?

AV: Before the interior design comes the architecture of the coach. We were very lucky to work closely with the brilliant engineers from the German Aerospace Center DLR to develop a very lightweight coach structure with generous windows within the extremely confined British loading gauge. Now the interior design has to provide the skin for the engineering and architecture of the coach. It is everything you touch with your senses: with your hands, your eyes, your ears, even smell. This is all essential when you think about colours, materials, illumination, ventilation and heating. You have to understand your design not only from a technical and standard point of view, but from a human point of view. It is not only about durability, maintenance and cleaning, it is about supporting the passengers to experience the relaxation or excitement of travel, give them a temporary home or office. Psychological and physiological comfort. A feeling of safety and trust. All this flows directly into design decisions and the value of this design process for the interior should not be underestimated, especially in trains. Airline operators understand this much better, because there is more competition.

RN: Which materials and finishes did you use in the train’s construction and interiors that are not usually found in trains today? Did any of these materials come from your aerospace research? If so, which?

AV: All materials used are train-graded and available for train outfitting. However, usually you don’t find it in this combination in trains. This has several reasons. Our approach, however, comes from our airline background, where the choice of materials is also limited by especially fire regulations, but the choice and possibility of the development of patterns and colours is much higher, since all airlines want to be individual and distinguished. This means, we thought of the train as designing an airline interior and only then started to research the availability of stock products. We also looked at many trains and clearly defined what we didn’t want: interiors which look like refrigerators and unmotivated funny and dark colours and wild patterns on seats and carpets, unfortunately often found in public transport.

RN: To provide some context for readers: Why do you (and your client, I assume) think it makes sense to focus design efforts on, and invest in, rail infrastructure today?

AV: Trains were the very first means of mass transportation more than 150 years ago. Trains today are some of the most environmentally friendly and safest means of transport and the development of trains in UK is a story of success. The number of passengers has doubled over the last 20 years and the number of journeys is expected to double again over the next 25 years.

Trains are fast, don’t suffer traffic jams and bring you directly into the centre of cities. There are worldwide large investments into high-speed rail infrastructure.

Western Europe dominates the market, followed by Asia and the Pacific. North America ranks third, due almost entirely to its large freight rail market.

Lantal Textiles: Seating

Lantal Textiles: Seating

The Swiss company Lantal isn’t only known for high-quality products and services for the passenger transportation industries but also for its innovative spirit. As a manufacturer and refiner of premium textiles and a provider of many useful services, Lantal’s mission is to do everything it can to make travellers feel at ease en route. The high comfort of the passenger was also a main objective while designing the AeroLiner3000, therefore a collaboration between the two parties seemed like an ideal combination.

Lantal’s involvement in the project started with a request from the Swiss architect Andreas Vogler from the Munich-based Andreas Vogler Studio. Mister Vogler knew Lantal already from the aircraft business. He approached the company with the inquiry to sponsor their high-quality leather for the mock-up of the AeroLiner3000 at InnoTrans 2016. Lantal leather is made of first-class central European cowhides with a subtle grain and a polished surface and is also in compliance with all relevant railway safety requirements. Lantal provided Mister Vogler with different leather samples and a colour card, which offered him a wide variety for the future look of the mock-up seats. After Mister Vogler found the right leather, that matched his vision for the mock-up, Lantal sent the final materials to the seat manufacturer Rica Seats in Finland. Rica Seats, which is known for its superior workmanship, then processed the leather on to the seats for the AeroLiner3000 mock-up.

The participation in a such pioneering and innovative project is associated to Lantal’s capability to analyse megatrends that influence passenger transportation. Lantal’s design team attends trade shows and exhibitions to obtain information on design directions, and researches the train market to better understand where the voyage will go for our customers and their passengers in the future.

Forbo Flooring

At InnoTrans 2016, we were delighted to see our Tessera FR flooring feature in Andreas Vogler’s full-scale mock up of the AeroLiner 3000. Tessera FR is a collection of attractive, hardwearing carpet, offered in various pile constructions and textures, all designed to deliver specific aesthetic and performance advantages. The installation of carpet in rail vehicles adds significant warmth, comfort and acoustic benefits.

This new double-decker concept aimed at Great Britain’s rail industry received a lot of attention at the show. The UK has yet to see a viable double-decker model that will tackle overcrowding issues but Andreas Vogler’s concept fits within maximum height/width restrictions and increases capacity by 30%.

The design has been incredibly well thought out, right down to temperature control – heat will be controlled by passengers with an app, which will gauge an average response and set the temperature accordingly. What’s more is that each window section can be dimmed by passengers if the light from outside is too bright. The interior design scheme can only be described as quite beautiful. The natural, muted colours are calming and aid the relaxation of passengers. The wood finishes and modern textures could have been used in a hotel or someone’s home – walking through the carriage was like walking on to a private jet – a feeling which was at the forefront of Andreas Vogler’s design vision.

FOR ALL THE LATEST INFORMATION, NEWS, IMAGES, VIDEOS AND ARTICLES ON ALL ASPECTS OF ROLLING STOCK, PLEASE CLICK HERE.