150 Years of Robel – Turning History into the Future at iaf

In 1875, Georg Robel founded a file factory in Munich.

Just 25 years later, it developed into the first and, for decades, only German specialist factory for track maintenance machines.

The claim to be a technology leader in developing high-quality, cost-effective machines for global use on the track has formed the basis of the Robel brand ever since.

At the iaf in Münster, the companies of the Robel Group will demonstrate that, even after 150 years, Robel is still a pioneer in solutions for infrastructure maintenance: Hand-guided, rail-bound, and robot-assisted track maintenance machines and measuring systems will be in operation in the open-air area A in front of the South Hall. With alternative drives, semi-automated processes, and services throughout the entire machine lifecycle, Robel is responding to the challenges of the railway system.

Decarbonization & Environmental Protection

- With new grinding and drilling machines, rail jacks, and track carriages, Robel Machinery & Tools will demonstrate directly on the track what the future holds in the areas of alternative drive technologies and ergonomics. New 800 Wh batteries enable data readout via Bluetooth/Wi-Fi for the first time.

- The service provider Plasser Robel Services demonstrates sustainability through retrofitting with a completely redesigned SSP 110 SW ballast leveler, modernized according to the latest (environmental) standards.

Demographic Change

- In response to the shortage of skilled workers, the automated ROWRENCH 8- spindle wrenching machine delivers precise work results in the shortest possible time. At iaf, Robel is showcasing the EU version with automatic spring clip insertion and removal for the first time.

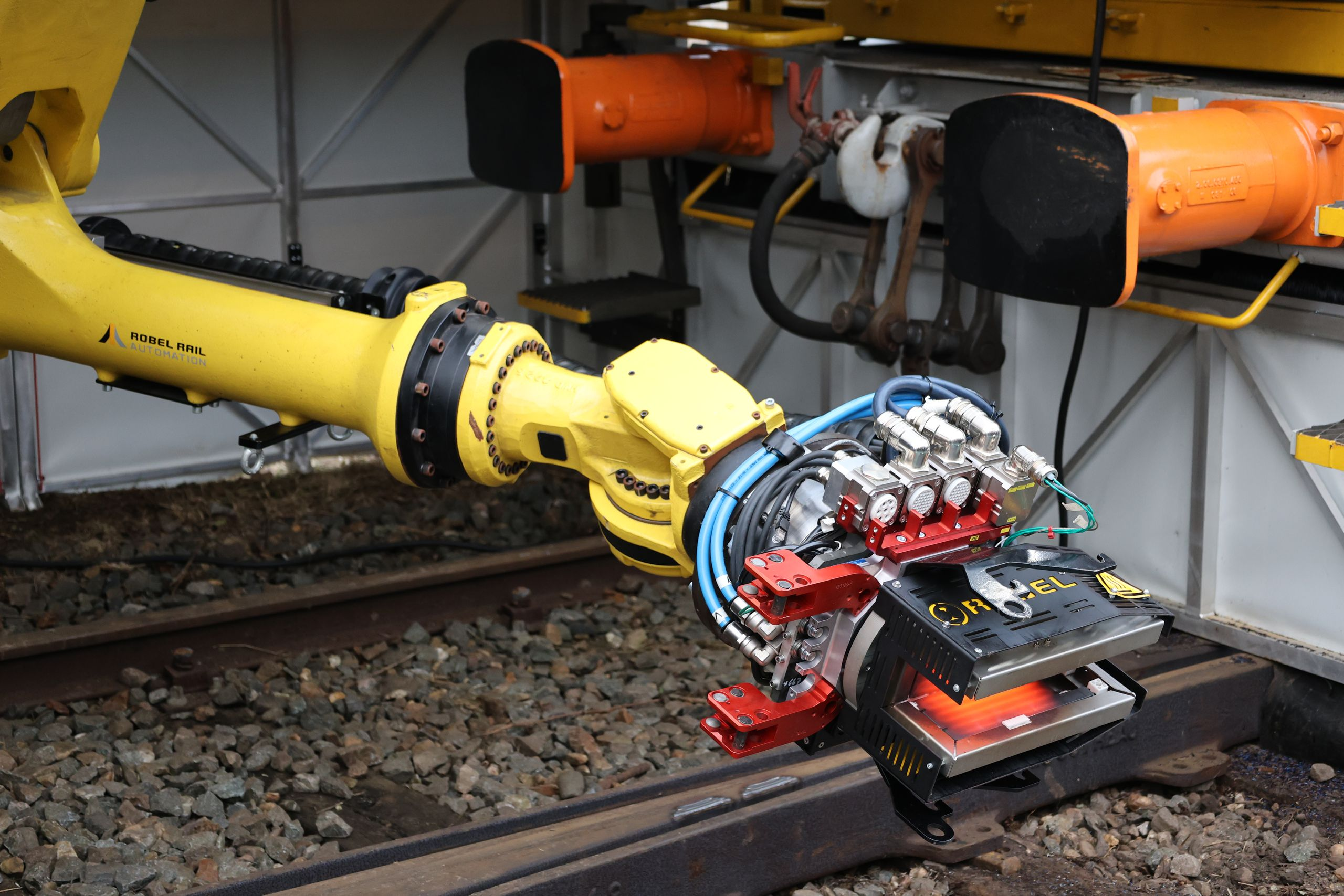

- Robel Rail Automation is presenting the fully automated welding of manganese crossings in the ROBOT Container and is introducing the “Homologation of Rail Welding” project from the Netherlands to the iaf trade audience.

Digitalization

- With MessReg IMU and MessReg CTS II, Vogel & Plötscher is showcasing new developments in the field of digital track geometry measurement in combination with software solutions from Plasser & Theurer partner TMC.

- The 002 Series of the ROSPECT modular inspection platform from Robel Rail Automation records track geometry and is equipped with a 3D environmental scanner and ground-penetrating radar antenna. Here, too, the software visualization is carried out in collaboration with TMC.

all relevant track parameters in real time

The ROBEL Group at iaf:

- A-403 – A-405

- PRS: S-430

Excerpt From ROBEL Group iaf Exhibits 2025 (Subject to Change):

- 150 years of the brand ROBEL | From “Rottenwagen” to RORUNNER & Co.

- ROGRIND 13.45RS grinding machine | ROLIFT 43.25 lifting machine | ROLLY 50.17 transport wagon

- ROWRENCH 30.77 automated 8-spindle precision power wrench

- ROBOT Container | Automated switch maintenance

- ROSPECT Measurement and inspection vehicle

- Vogel & Plötscher Mess Reg IMU for digital track position measurement

- PRS | P&T SSP 110 SW after full Retrofit

This article was originally published by ROBEL.