The Future of Rail Automation

Smart Mobility – Facing the Challenge

“Automated rail will be the backbone of future transportation. Smart rail technology will meet demand for capacity growth, optimise operations and reduce costs, but this significant sea-change in service delivery will require the rail industry to step-up to new safety and security challenges.”

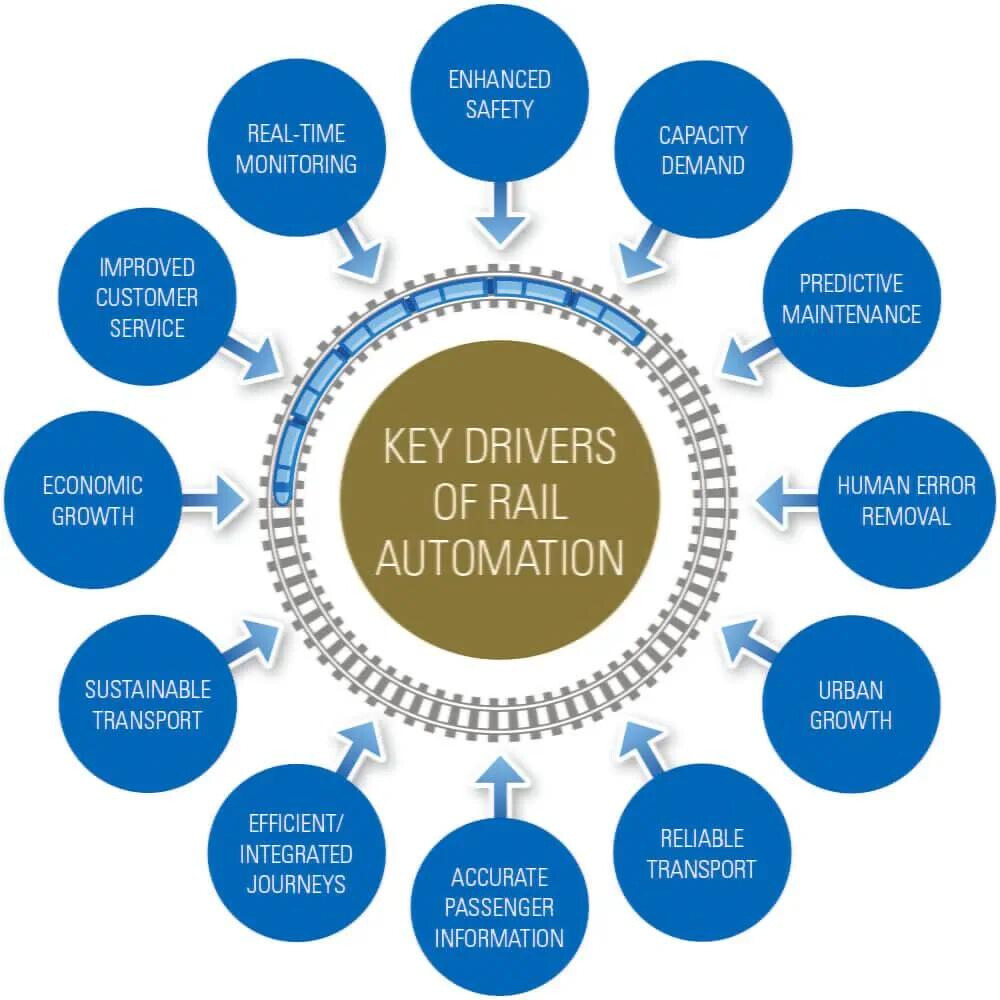

Rail Automation Drivers

The rail industry is faced with rising demand for passenger and freight capacity, alongside an infrastructure that is struggling to keep pace with the rapid rate of urbanisation. The passenger of the future will expect a seamless travel experience, with on-time connections and on-demand travel information. Consequently, a technological renaissance is delivering innovations in driverless trains and passenger information, as well as rolling stock and infrastructure monitoring introducing a move away from ‘time-based’ to ‘condition-based’ maintenance scheduling.

Driverless trains bring many advantages to operators, authorities and users, in terms of increased safety, reliability and flexibility, with metro systems spearheading this automation catalyst. According to a UITP report, as of July 2016, there were 55 fully automated metro lines in 37 cities around the world. Currently totalling approximately 789 km in length, the projection is that by 2025 this will rise to over 2,300 km. The UITP report also states that following successful conversions of both U2 in Nuremberg in 2009 and L1 in Paris in 2012, six European cities have confirmed conversion projects in the coming decade.

The Future’s Smart

New technologies are delivering intelligence to the rail infrastructure, enabling it to increase capacity at a faster rate, while enhancing operational, environmental and safety performance.

As the railway systems become smarter, there will be an increase in:

- Connectivity – intermodal and across operational borders.

- Passenger involvement – information systems enabling a more active passenger role.

- Predictive maintenance – condition/health monitoring of physical assets and systems.

- Condition based maintenance – a large number of sensor-based data collection points.

The rail industry could learn from the experience of other industries, such as automotive, where sensors are already deployed successfully. Traditional engineering solutions will therefore be supplemented increasingly by cognitive technologies, which anticipate breakdowns and avoid accidents. For example, smarter urban railways could see the deployment of multiple sensors, such as cameras, radar and infrared. This would deliver increased safety through innovative analysis algorithms, which would lead to more intelligent systems. Moreover, predictive maintenance, supported by asset information systems and networked technologies for condition monitoring of physical assets, will become a key element to ensure reliable operations and significantly reduce costs.

Safety and IT Security Challenges

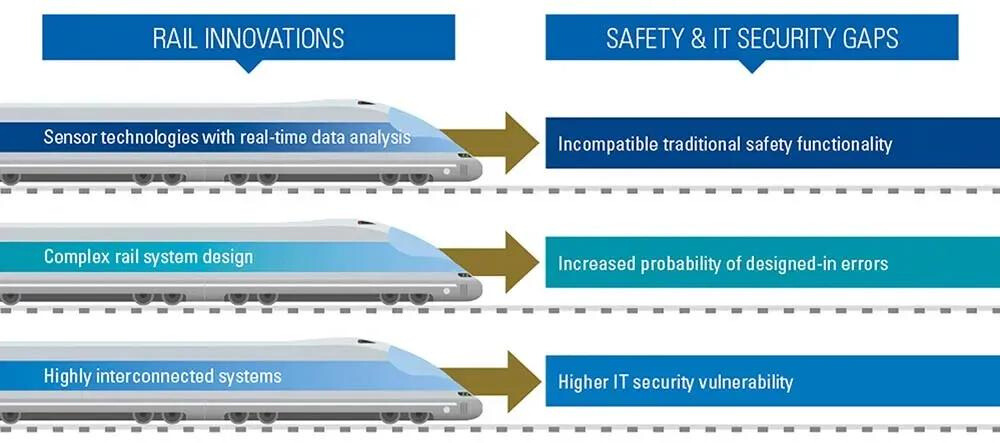

While technological developments will deliver immense benefit, they will also create new safety and IT security assurance challenges, similar to those experienced with Industry 4.0. For example, current functional safety approaches for railway systems are not completely aligned with the needs of new sensor technologies, when combined with real-time data analysis. Likewise, complex autonomous system designs with a high number of safety functions are more prone to designed-in errors, increasing the need for simulation and modelling aids during the design and testing phases.

Furthermore, as communication between vehicle systems and infrastructure increases, IT security of complex, digitised and interconnected processes will become more vulnerable. To offer improved protection against cyberattacks, new automated systems will therefore require different safety assessment approaches to those currently used for more traditional systems.

When New and Old Rail Systems Converge

Delivering Safe and Secure Innovation

Increased rail automation must reduce safety risks to an acceptable level, including hazards caused by complex system malfunctions. At the same time, IT security measures need to address performance requirements without disrupting safety functions. Risks and vulnerabilities must therefore be identified, and functional safety and IT security be optimised to ensure compliance.

TÜV SÜD has more than 50 years’ experience of working with European and international rail systems. We are the experts at closing the gap between rail safety and IT security compliance approaches, as well as accelerating the homologation process of new automated rail vehicles. Focused on supporting clients to develop new technical solutions that meet the challenges of rail automation, TÜV SÜD harnesses the skills of its international network.

This article was originally published by TÜV SÜD.