Sure-Fire Rail Flooring Solutions

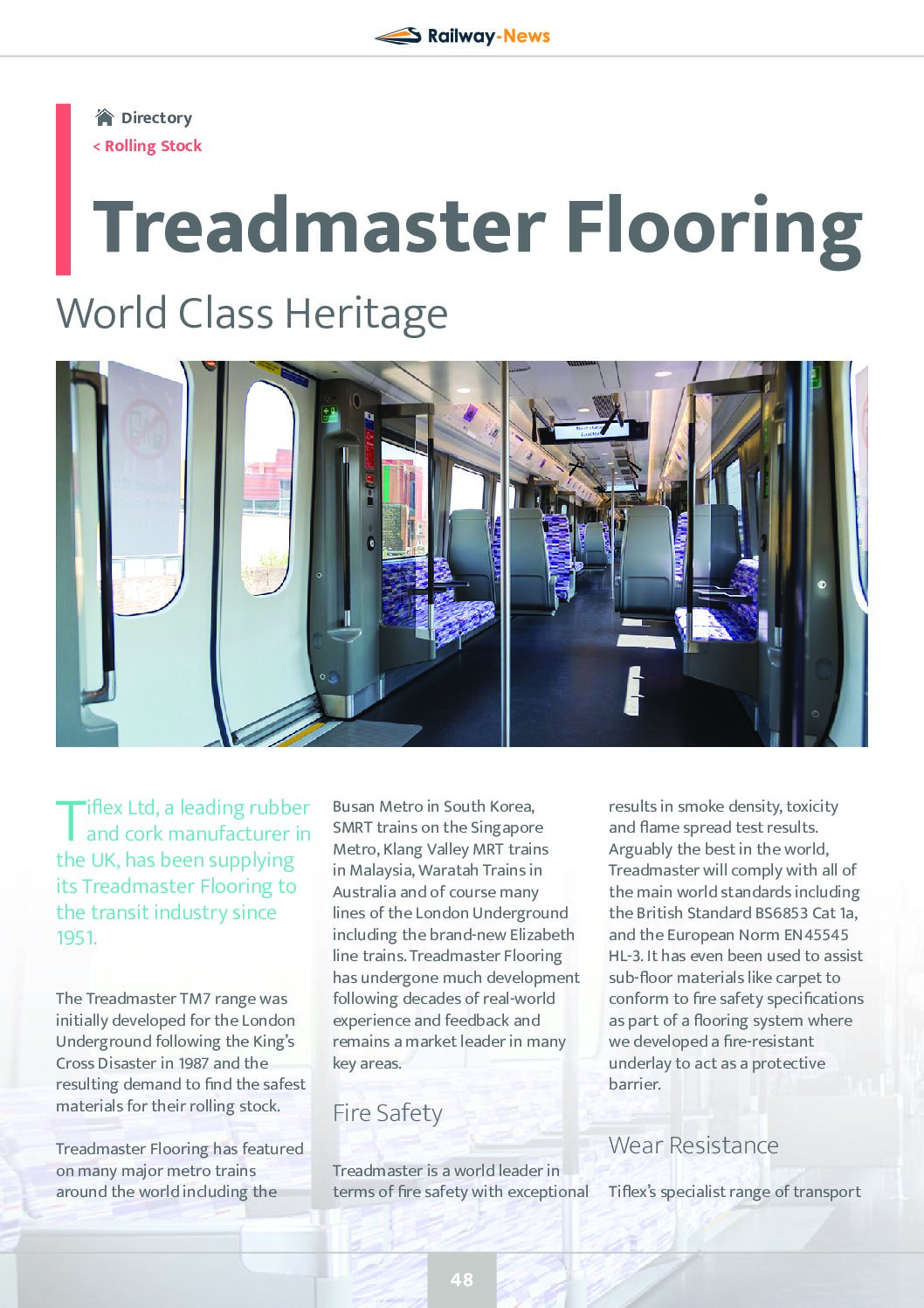

UK Rail Floor specialist, Treadmaster (a Division of Tiflex Ltd) have been supplying their flooring to the transit industry since 1951.

With a proven worldwide reputation for quality and performance, the team at Tiflex provide an environment of continuous development and innovation, supported by an extensive list of references from some of the world’s major Rail OEM’s.

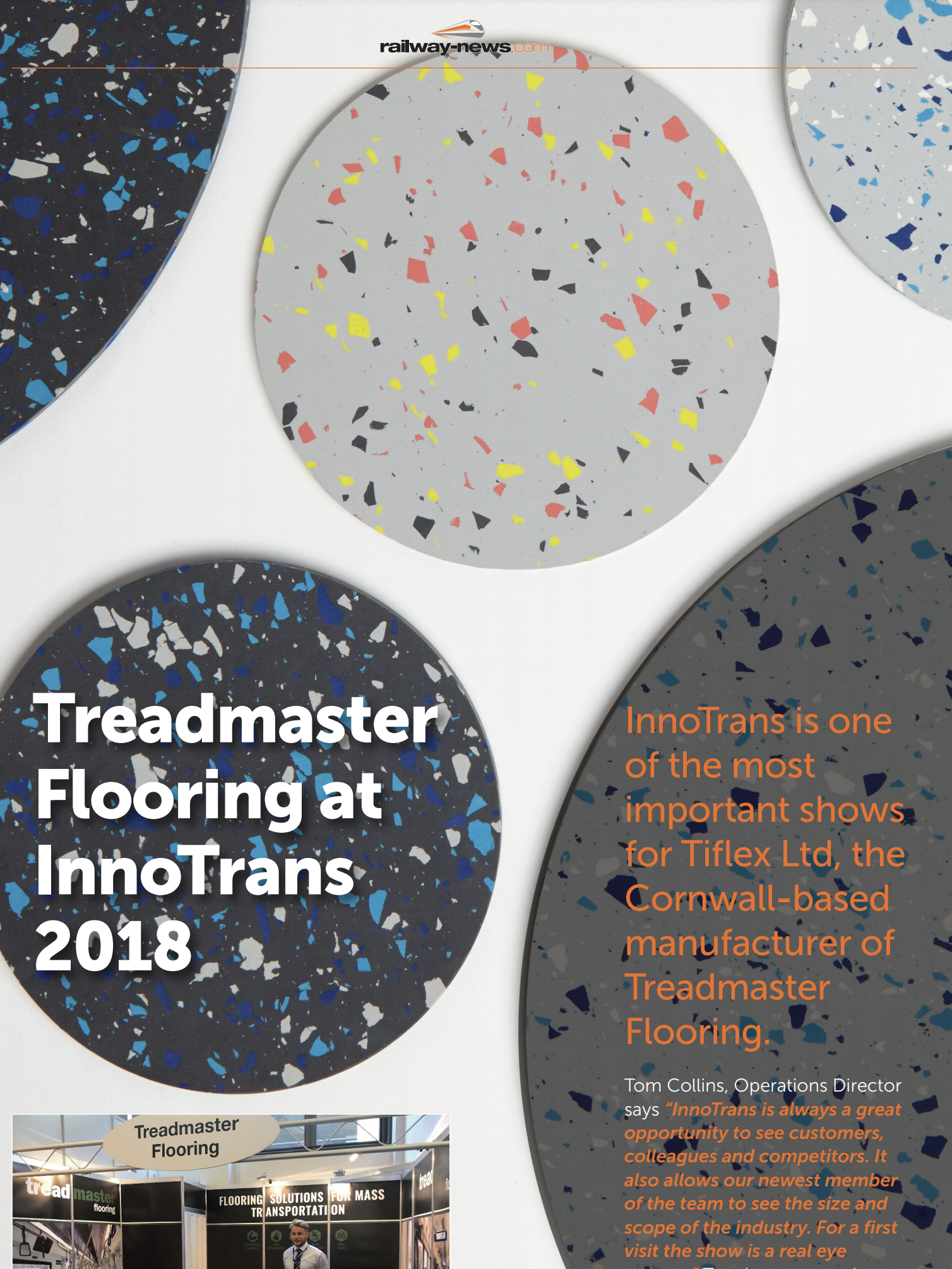

From its base in Cornwall, Tiflex manufactures Treadmaster and produces an extensive, diverse range of fire retardant rail flooring solutions. We pride ourselves on an evolving product range suited to assist an evolving market driven customer base. High quality standards together with our involvement in high profile projects, Treadmaster has become a market leader in Fire Retardant Floor coverings for the rail and mass transportation sector.

Tiflex has a state of the art test facility, approved to the various rigorous quality standards demanded of today’s requirements. Coupled with an extensive product development laboratory. We comply with standards such as BS, EN, NF, UIC and ASTM.

All Tiflex products are manufactured in a BSI registered factory operating a Quality Management System which complies with the requirements of BS EN ISO 9001:1994.

Tiflex is part of the James Walker Group of Companies.

Fire Retardant Rail Floor Coverings

Treadmaster was first developed for London double decker buses in the 1950’s and has been used in public service vehicles around the world ever since.

Nowadays Treadmaster supplies most of its flooring to train builders rather than bus builders but was still called upon to supply flooring to the recent reincarnation of the London Routemaster bus designed by Heatherwick Studio and built by Wrightbus which entered service in the capital in 2012.

In 1987 following the tragic Kings Cross Underground fire, stringent new rail fire standards were introduced for all materials in use on the underground. These new standards were the catalyst for Tiflex to develop its range of compliant, highly fire retardant rail floor coverings.

It didn’t take long for these products to be adopted by rail operators such as London Underground and to this day remains one of the most tried and tested products in service.

The first thing passengers consider when they step on to a new or refurbished train is the aesthetics, the colours and comfort of the new interior. Probably what very few consider is how safe is this train in the event of a fire.

Thankfully these types of incidents are few and far between but when they do occur how confident can fare paying passengers be that the materials specified meet the requirements in scenarios such as fires.

History demonstrates that it takes a tragedy to make us sit up and ask questions such as “why was this particular type of material used in a passenger environment”? It is only after the event that a change of legislation or adoption of new standards occur.

Rail Compliant Floor Coverings

In rail, fire standards are much more stringent than for land based buildings but the fundamental principal should always be the same – safety should never be compromised over costs.

As of 2018 the New European Rail Fire standard EN45545-2 is mandatory across Europe and is set to take over from existing national standards such as BS6853. The key focus of this is to harmonise rail fire standards across Europe making it easier for European companies to have access to the wider European market without having to meet all of the previous existing national fire standards.

In some quarters the new EN45545-2 standard is acknowledged as being less stringent than the existing national standards and as a consequence, some materials that didn’t meet the old national standards may now meet the new European standard.

Specifiers and operators should not feel pressured to reduce costs by using materials that would not have previously met the national standard but now meet the European standard.

Operators are well within their rights to specify products that meets both standards.

Fortunately for specifiers Treadmaster can offer robust rail compliant floor coverings as their TM7 flooring meets the BS6853 Cat 1a and EN45545-2 HL3 and TM8 meets BS69853 Cat1b and EN45545-2 HL3.

Our products are used across the globe when there is no compromise on fire safety for rail passengers.

Durable Rail Floor Coverings

As well as having a floor covering that meets the stringent fire safety standards for rail, another requirement which cannot be overlooked is durability.

With metro and commuter train services transporting hundreds of thousands of passengers every day durable rail floor coverings are essential to withstand this type of footfall while remaining easy to clean and maintain.

Treadmaster flooring offers unrivalled industry lifecycle costs as their synthetic rubber flooring offers incredible durability.

One additional benefit is that the material can be invisibly patch repaired. If there is an area of flooring that has been damaged this is simply removed and a new piece of material installed. Once the floor has been lightly sanded it provides an invisible, seamless repair.

Illuminating Innovation

As part of an ever increasing mission to enhance the safety benefits of their products, Treadmaster recently introduced a photo-luminescent material that can be used with their flooring for evacuation markers in the event of a main power outage.

Treadmaster are constantly trying to innovate and add to our portfolio of floor coverings and accessories for the rail and other sectors

Photo-luminescence seemed like a natural extension to the fundamental safety benefits that our floor coverings already offer and we are delighted that Bombardier and QNGR were the first to adopt this new technology that we have developed.