How 3D Printing is Transforming the Rail Sector

With passenger rail increasing in popularity as the solution to multiple transport needs, from inner-city commuting to regional travel, the expectations of comfort, function and styling of train interiors are becoming more prominent amongst travellers and critical differentiators for operating companies.

Additive Manufacturing (AM) allows for the design and manufacture of low-volume, complex components, allowing operators to configure and customise their passenger trains to a region or city, or even to a specific route.

Operators can then better meet the exact needs of their passengers within specific commuter zones. For example, incorporating integrated electronics and storage features, reconfiguring seating and standing areas or adding styling through the cabin that reflects the local aesthetic or identity.

How Our Innovation Could Help You

With so many train interior design possibilities, how and where do you start? Stratasys can assist you in identifying, prioritising and validating Additive Manufacturing train interior concepts through Innovation Workshops delivered on-site by consultants. By applying our rigorous, AM focused innovation process, alongside our years of experience working with companies across all sectors to innovate new products and business value uniquely enabled by AM, we can work with you to generate actionable AM concepts that are technically feasible, commercially viable and add the greatest value to your business.

Let Stratasys shape your 3D printing future. Find applications within:

- Interior design opportunities.

- Integrated electronic housings

- Modular fixings

- Body panel and partition styling

- Ergonomic seating, arm rests and grips Benefits of 3D printing

- Ergonomic and functional customisation

- Aesthetic and styling personalisation

- Mitigation of CAPEX in tooling

- Elimination of economies of scale

- Carriage design and engineering opportunities

- HVAC ducting

- Wiring guides and clips

Additive Manufacturing provides unrivalled design freedom but is an unfamiliar manufacturing process to many engineers. Our consultants can help educate and guide you through every step of the journey from concept to fitted part. We will assist you with material and machine selection and help optimise your designs so that they are more cost effective for AM.

What’s more, we can even carry out cost estimation and supply chain planning to inform your procurement team of the realities of using this alternative manufacturing process.

Lighter and Safer

With the increasing pressure on rail vehicle manufacturers to improve the operational performance of their products, it is no surprise that Additive Manufacturing is being viewed as a potential solution to overcoming the engineering and logistical challenges in optimising cabin packaging, light weighting and structural design. But what specific solutions can Additive Manufacturing provide in this continuous drive towards better carriage design and performance? One area that Additive Manufacturing naturally lends itself to is the printing of components for HVAC & electrical systems.

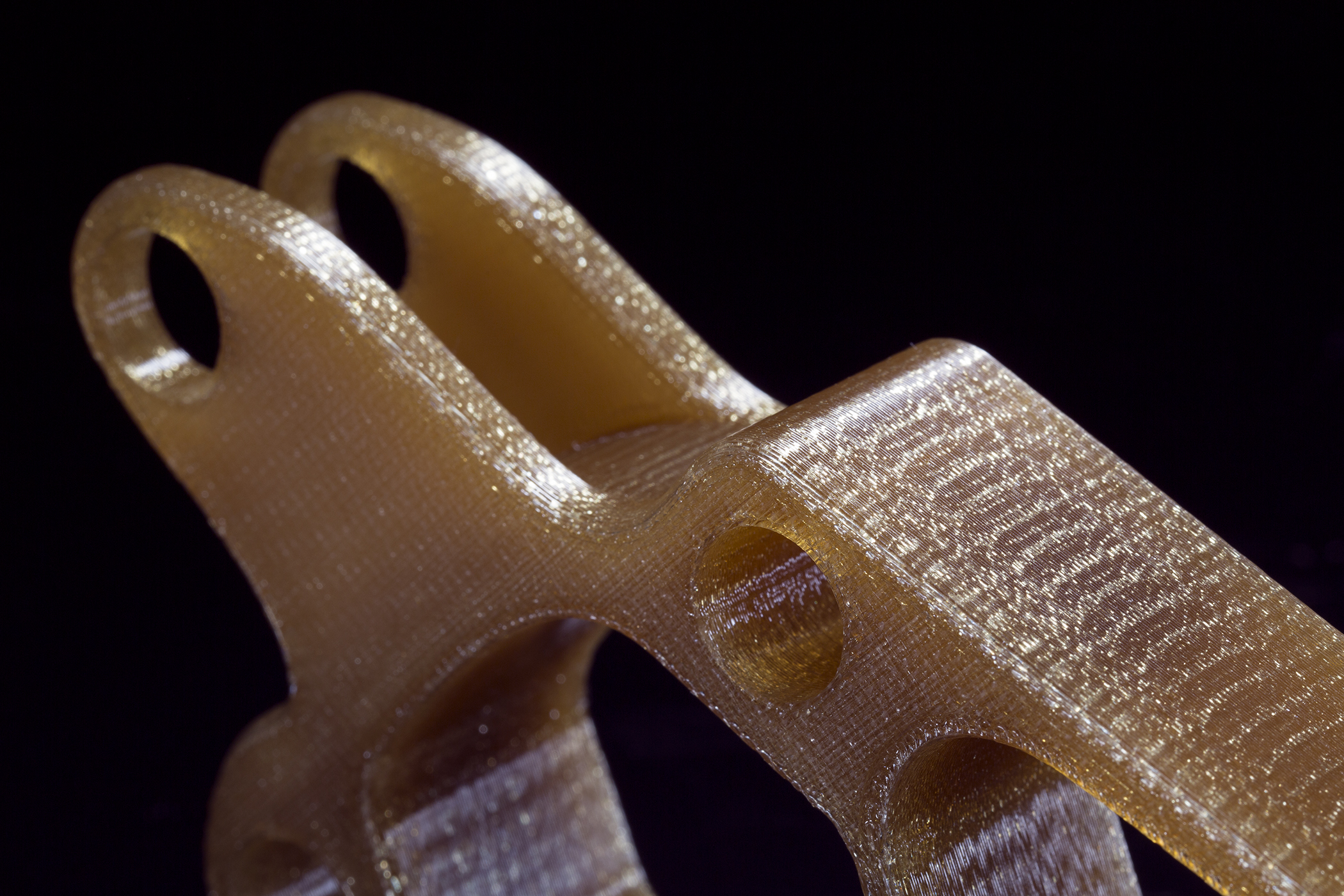

The aerospace industry as an early adopter of AM currently uses the technology to manufacture ventilation ducting and advanced HVAC systems, all of which have been tested and certified safe and many of which could be rapidly adopted and integrated into train carriage design and manufacture today. Another pressing demand on carriage design is the drive towards light weighting rolling stock, particularly now with a private and public push towards electrification and energy efficiency improvements. By eliminating the need for tooling, Additive Manufacturing grants a much higher degree of design freedom which in turn allows for topological optimisation of parts and consolidation of assemblies, both of which can eliminate waste in part design and reduce the overall weight of a component.

Process Improvement

Evaluating your facility and inventory data to find 3D printing applications that will improve your operational efficiency. Opportunity validation Assessing the technical viability and economic feasibility of using 3D printing as a production solution for your application. Design for Additive Manufacturing Exploiting the design freedoms of AM by providing deep design advice and sub-contract design services.

More Innovation. Less Inventory.

Additive Manufacturing offers many advantages for maintenance, repair and overhaul for the rail industry such as the rapid and direct manufacture of components from a digital part library at the point of need. Siemens Mobility have been utilising this capability by building a virtual warehouse of 450 different components, all of which can be 3D printed when needed.

Combining a digital library and on-demand, on-site production, Additive Manufacturing can greatly reduce the need for spare part holding, free up working capital from tied up inventory and reduce the maintenance down time of your fleet. Beyond spare parts, low volume manufacturing from a digital parts library can also help to greatly increase access to low-cost, customisable jigs and fixtures to further streamline the maintenance, repair and operations of your business.

How we make your processes smoother. Our Consulting team has significant experience in identifying spare parts and manufacturing & assembly aids which could be manufactured using AM to improve their functionality, improve availability and reduce production and inventory costs. By assessing your digital part inventories, maintenance management systems and SRM/PLM systems along with on-site facility inspections, we can also identify the procurement, reliability and quality issues where Additive Manufacture can work as a production solution to increase efficiencies and reduce costs within your MRO operations. Get in touch.