Sound Isolation Systems for Transport

Pliteq is an engineering firm dedicated to the design and manufacturing of sound isolation systems for transportation, commercial and residential applications. Harnessing the natural sound and vibration damping properties of rubber, our patented solutions provide effective and efficient reduction in noise and vibration for ballasted or floating slab track applications.

Commitment to research and development is what sets us apart. We have patents registered in 23 countries worldwide and have several more patents pending and under development. Pliteq engineers have completed over 700 acoustical laboratory tests in the last ten years, and have committed to a monthly testing schedule as we consider only recent test data to be relevant for engineering purposes.

Pliteq is continuing on a growth trajectory and is a leading innovator in acoustic vibration and sound control on a global scale.

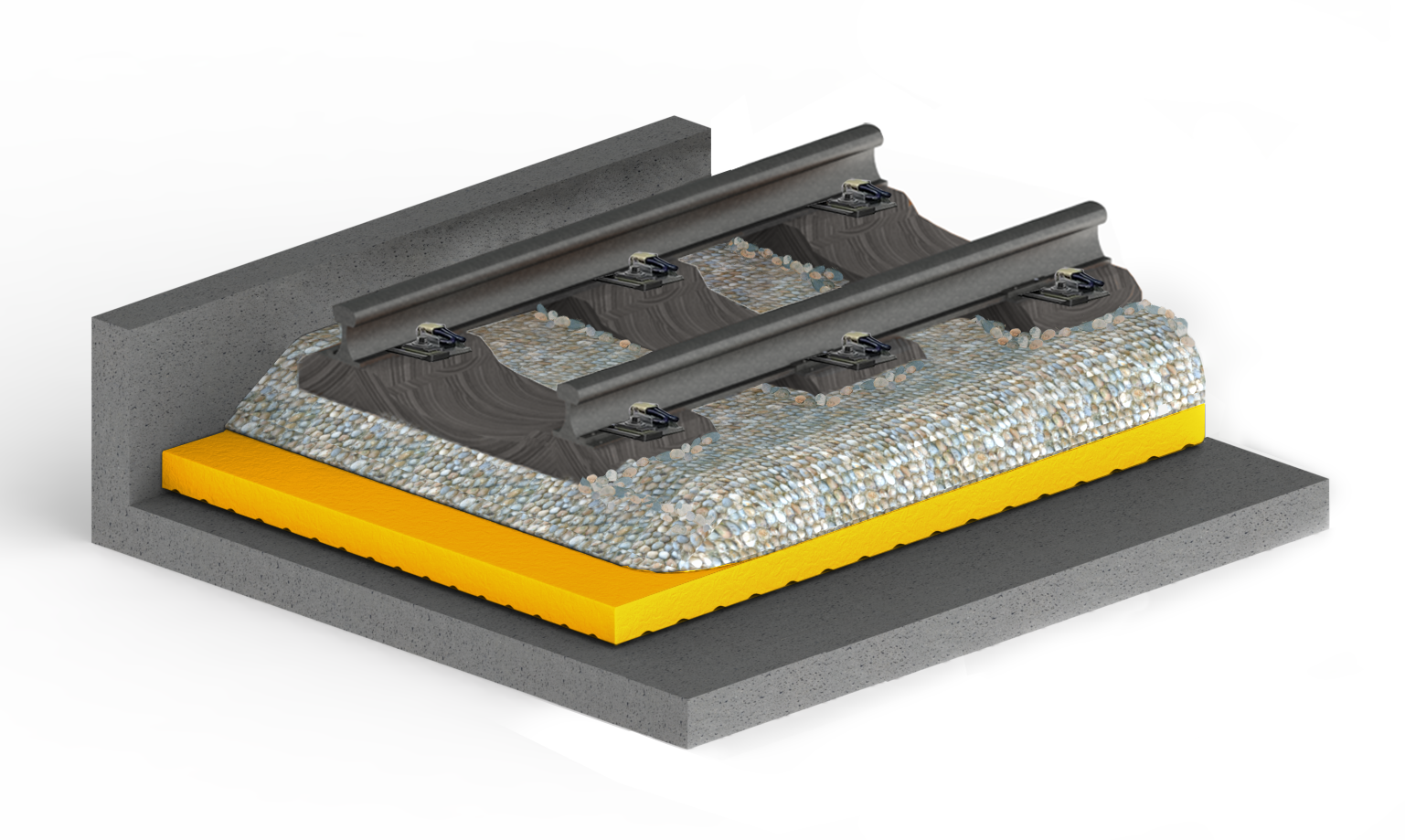

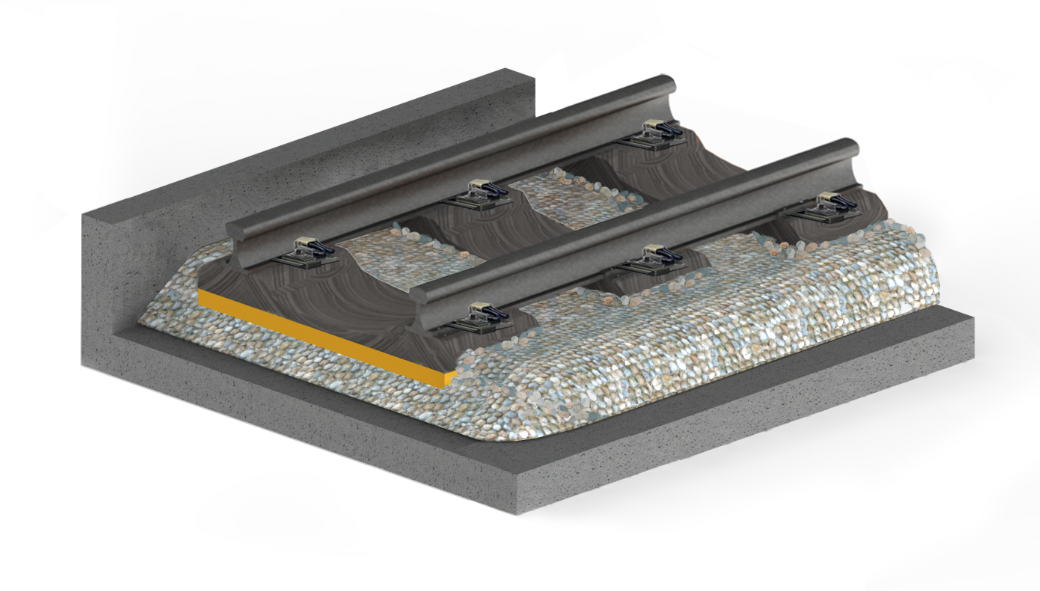

Ballast Mats

Installed directly beneath the ballast, ballast mats are in many cases the most efficient means of impact and vibration reduction. Pliteq GenieMat BST is tailored specifically to your project and features a protection layer designed to withstand millions of loading cycles.

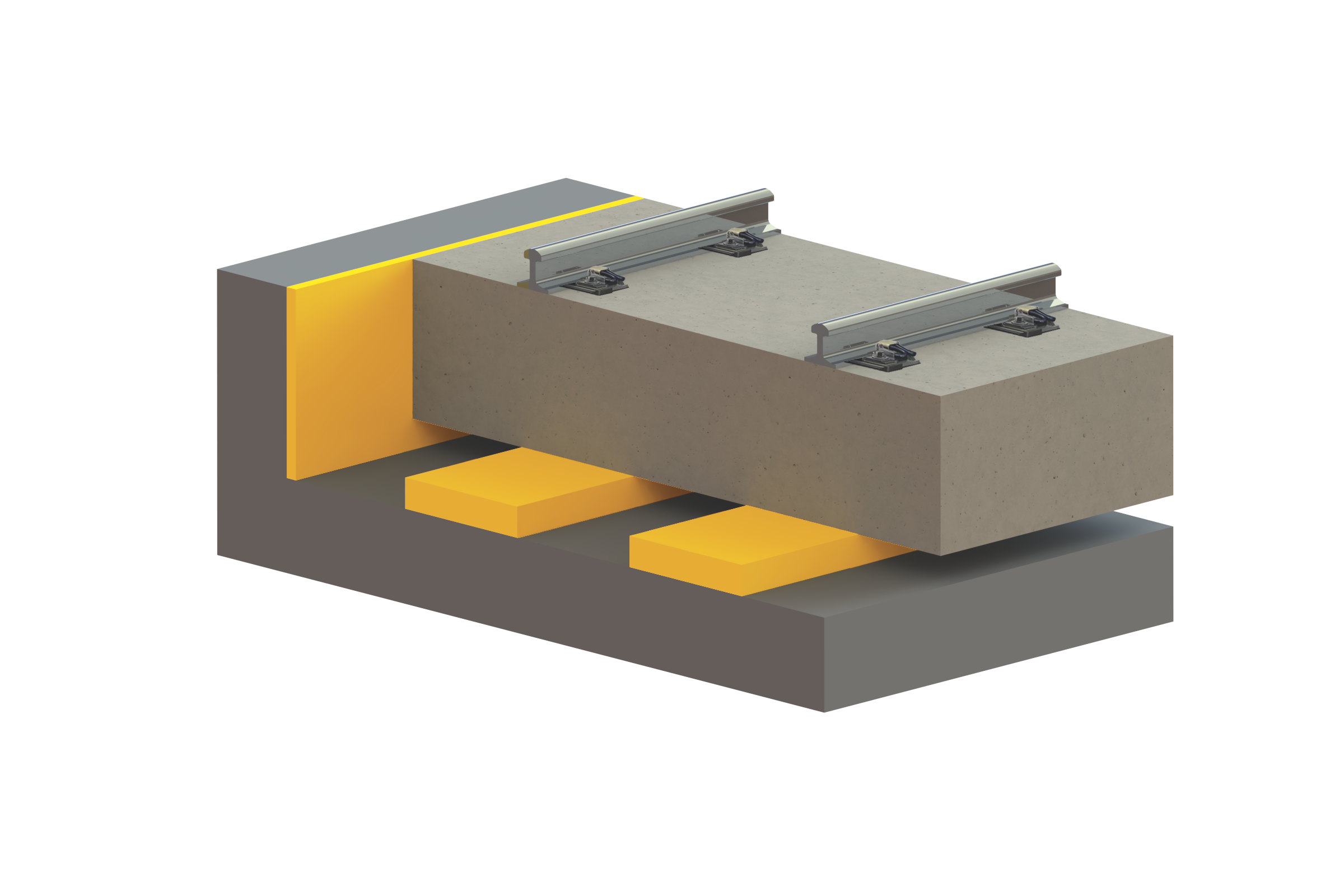

Floating Slab Tracks

This is an isolating element that sits between the floating slab and the structural trough below. For substantial ground-borne vibration mitigation, a mass-spring system is considered the most effective vibration isolation design.

GenieMat FST isolators are designed to meet project specifications in continuous, linear, and discrete configurations.

Tie Pads

Railway tie pads disperse load, reduce impacts, and increase ballast stability by allowing ballast embedment.

Embedded directly into ties during the manufacturing process, Pliteq GenieMat RTP is designed to disperse load and reduce impacts in the most cost-effective manner.

Your project might be connecting countries, cities or blocks and could pass under, over, and through various landscapes. Each will require a differing system to suit both the landscape and the rail type. The principles applied by GenieMat RAIL products remain the same: reduce vibration at the source to mitigate the impact on the local surroundings. Insertion loss and dynamic rail deflection are two project specifications which will help determine the correct product to use.

Using these characteristics in combination with the actual or predicted vibration levels will aid compliance engineering.