Sustainable Welding Solutions for the Rail Sector

Since 1935, Holland has pioneered innovative rail services and products. With the largest fleet of MobileWelders® globally, we are proud to be the industry leader in flash-butt welding. From track measurement to load securement products, we strive to be a true solutions partner to the rail industry.

Rail Welding

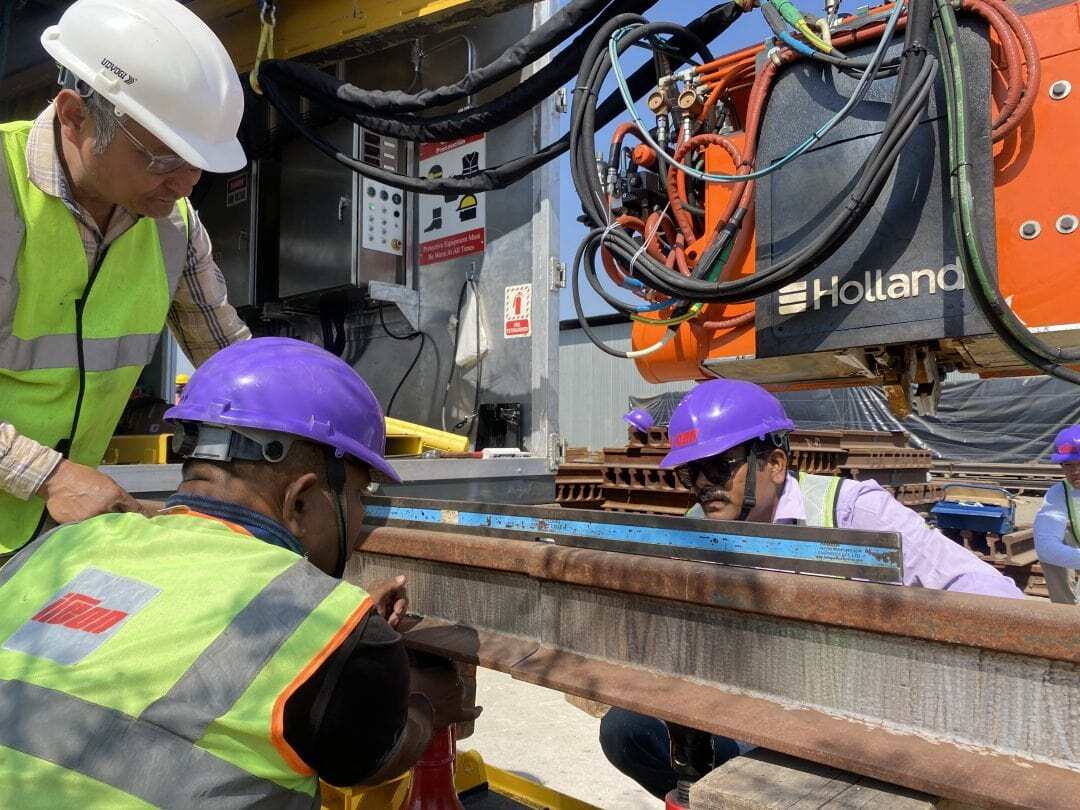

Holland’s proprietary Intelliweld® control system offers enhanced efficiency through real-time weld monitoring and remote diagnostics, delivering an industry-leading uptime of > 98% and weld quality conformance of >99.9%.

Used on its fleet of ~200 MobileWelders in North America and Australia along with units welding on high-speed rail projects in Japan and India, Intelliweld is being released for applications and customers worldwide in 2025.

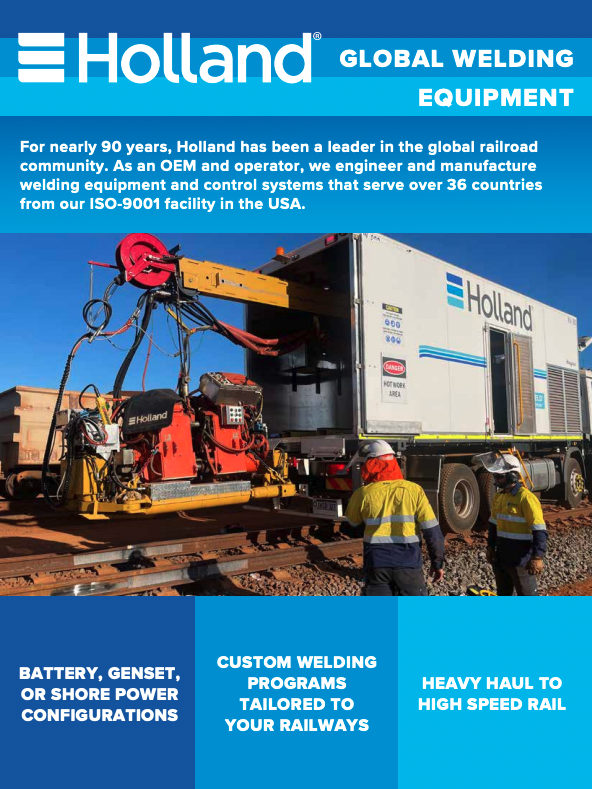

Rail Welding Equipment Manufacturing

We design, manufacture, operate, and maintain our own equipment, allowing us to be the most efficient and innovative. Sales assistance, leasing options, service, replacement parts, training, and ongoing support for our flash-butt welding equipment are available in over 36 countries.

Sustainable Welding Solutions

Holland has also spearheaded sustainable rail welding solutions with the development of our Hybrid Welder.

Holland’s Hybrid Welder™ features the same industry-leading equipment as a traditional MobileWelder®, with a battery-powered welder head. This allows us to deliver the high-quality flash-butt welds Holland is known for in a more sustainable package. The Hybrid Welder delivers decreased fuel consumption and emissions, reduced noise and compliance with future emission requirements while avoiding equipment down-time associated with stringent emission requirements on traditional generator.

Track Geometry Measurement

Holland’s Argus® Track Measurement Technology and Rangecam™ Software provide industry-leading track measurement technology and services via our TrackSTAR® fleet, portable and locomotive UGMS solutions.

Conventional track geometry and rail profile measurement systems are very costly due to requiring dedicated rail-bound or hi-rail vehicles, trained operators, and occupying revenue service tracks. In addition, sufficient measurements are not taken for trend or predictive analytics.

Holland brings a new perspective to track measurement with two innovative product lines to solve the core problems of conventional track geometry systems: Argus Portable Inspection Systems (Gauge and Track Inspector) and Argus UGMS/ATGMS (Freight or Passenger Locomotive and Rail Cars). Argus is a low-power, modular, compact, non-contact, inertial-based technology with measurement speeds up to 150 mph and operates in forward and backward directions.

We employ a diverse, talented, and innovative workforce committed to providing the highest quality products and services. With multiple facilities across North America and Australia and partners in India, Turkey, Japan, Thailand and beyond, we are strategically located to provide our customers with the best products and services as quickly as possible.