Škoda Group has commenced the modernisation of Gothenburg’s M31 trams for Swedish carrier, Västtrafik AB.

This project aims to enhance the reliability and safety of the trams while improving comfort for both drivers and passengers.

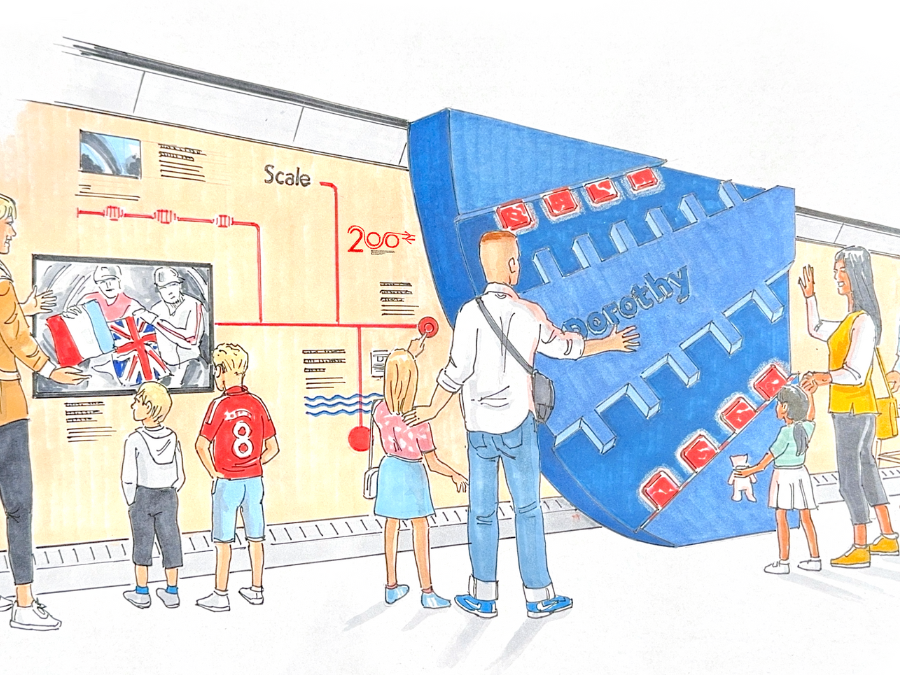

Alongside commencing work, Škoda has presented a visualisation of the final design, showcasing upgrades that maintain the original look of the trams while aligning them with the aesthetic of Västtrafik’s current fleet.

The modernisation work will be carried out at Škoda Group’s production site in Ostrava, Czech Republic and is scheduled to continue until 2028.

Jan C. Harder, President Region West and North Škoda Group said:We have a strong focus on the Nordic region, leveraging our extensive know-how in vehicles that can withstand the specific weather conditions found there. Our production in Finland has equipped us with the expertise to deliver reliable and robust solutions tailored for Nordic climates. We are excited to bring this capability to Gothenburg and offer a modernised fleet that will serve the city efficiently for many years.

Gothenburg’s Västtrafik currently operates a fleet of 79 M31 trams, all of which are slated for modernisation. These trams, originally built between 1984 and 1986, previously underwent significant repairs and upgrades at Škoda Group’s Ostrava facility between 2011 and 2017.

Gothenburg is experiencing growth in population and an increased demand for public transportation. The refurbishment of the M31 fleet is thus a key initiative to ensure the city’s transportation network can meet these demands.

The refinements will significantly increase the safety, reliability, and comfort of the trams, extend their service life, and provide a better travel experience for passengers. The first modernised trams are expected to be handed over to Västtrafik by the end of this year.

One notable change is the installation of a modern electric door system to replace the outdated pneumatic system, featuring new footsteps and LED warning lights for improved safety. The mechanical braking system will be upgraded to a modern electro-hydraulic system, enhancing overall safety. Additionally, a new boarding ramp for people with reduced mobility is designed to ensure reliability in Nordic conditions.

The driver’s cab will also be refurbished with LED controls that are easily visible in sunlight, while maintaining original ergonomics and accessibility. Drivers will benefit from an improved cooling and heating system directly in the cab. The passenger compartment will see new seat covers, LED lighting, a revamped seating layout, and enhancements to the heating system.

The modernisation efforts will ensure that the trams remain operational for at least another 15 years, supported by a spare parts guarantee.

Jan Gutovský, Head of Project Management at Škoda Group said:The trams will undergo a comprehensive modernisation at our Ostrava production site, which includes new door systems, a modern electro-hydraulic braking system, improved heating for passengers, and air conditioning for drivers. Technical solutions were designed to withstand Gothenburg's tough climate. We currently have a total of four trams in our production, with the first ones already undergoing initial modernisation work. The first prototype tram is in the painting stage, and we are preparing for assembly work, while the other vehicles are undergoing bodywork modification and repairs.