“You can’t control what you can’t measure…”

This quote by Peter F. Drucker from management theory can also be applied to railway and its condition assessment. Only if the condition of the track can be determined it is possible to initiate the right measures to correct faults or prevent serious damage such as rail breakage and rail destruction. In this way, modern track measuring devices make a decisive contribution to safety to the overall rail condition.

The German track measurement specialist Vogel & Plötscher (V&P) focuses on three components of the rail condition: longitudinal rail profile (corrugation and waves), transverse rail profile (comparison between actual and target rail profile as well as metal removal) and the detection of rail defects. And for that, V&P uses a magnetic flux leakage testing procedure: the RSCM.

Rail Defect Detection Methods

The timely detection of rail defects is a key topic for operating safety on railways. In time, different methods and technologies have been introduced. Ultrasonic testing has been used successfully since the 1950s to classify the state of damage inside the rail. This technology has limitations in properly rating rail defects within the rail’s near surface area (= section of about 0.1-6.0 mm depth) depending on the sensors used, distance to the surface and local conditions. However, certain types of rail flaws such as cracks, head checks and squats occur precisely in this near-surface area and are the cause of serious consequential damage. These defects can also be detected by eddy current technology. However, the limitations of eddy current technology are, that only the first 2-3 mm of the rail surface can be detected on a specific part of the rail head.

The RSCM

With this background, the RSCM, Rail Surface Crack Measurement, flux leakage technology was developed and covers a niche in the detection of rail defects. The great advantage of this method is that rail defects between 0.1 mm and 7.0 mm depth can be detected and analysed regardless of their angular position. For this purpose, the rail is first magnetised. If the rail has defects near the surface, an interaction occurs in the magnetic field specified as “flux leakage“. This changed magnetic stray field is then detected through hall sensors.

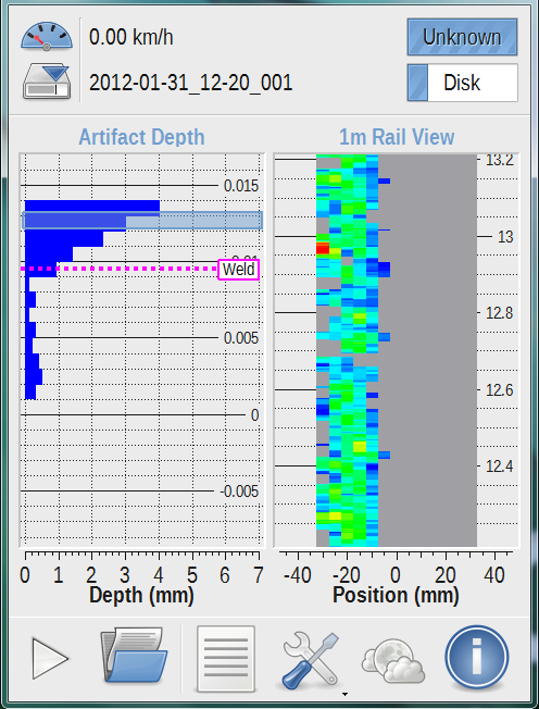

The raw signal from each sensor is filtered and analysed by an integrated software. As a result, two pieces of defect information are made available. Firstly, the largest measured defect depth is determined for each meter of tested rail. As the scattered magnetic flux is also proportional to the damaged volume, the geometry and damage intensity (by colour code) of the defect on the rail surface are also mapped (à picture 1). The system uses up to 19 hall sensors arranged next to each other in 5 mm distances, covering the complete transverse rail profile. The RSCM method therefore not only detects cracks on the rail’s running edge, but also defects on the rail‘s running surface, such as serial squats.

The measuring process is supported by multifunctional setting options in the software which are displayed during the data evaluation. While evaluating the rail surface, it is possible to add further information or set event markers.

On-Site Evaluation

All important information can be analysed in real-time during the measurement. The display of the device is divided into two parts. On the left-hand side, a 25 m section is displayed and shows the largest depth of each meter section in this area.

On the right-hand side of the screen, the operator gets a zoomed-in and detailed perspective on the one meter section.

Due to the capture of the raw data on the rail surface, the software generates a damage map showing the exact position of the various rail defects on the rail head on this highlighted one meter section. As the RSCM is showing the biggest defect depth in each meter section, the operator instantly knows the amount of material that must be removed from the rail profile to eliminate the defect to avoid further damages of the rail. Therefore, rail maintenance measures can be derived and initiated directly.

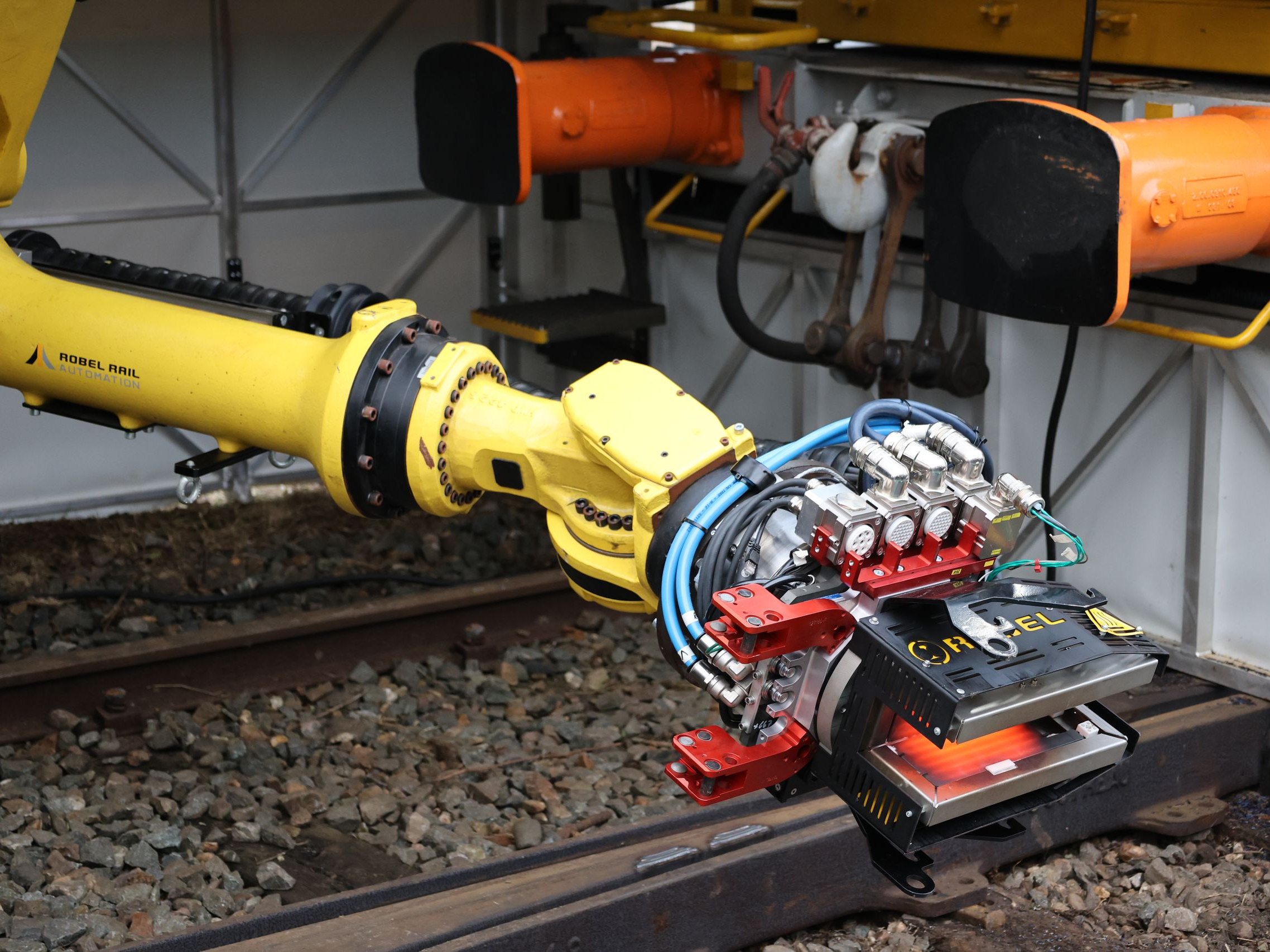

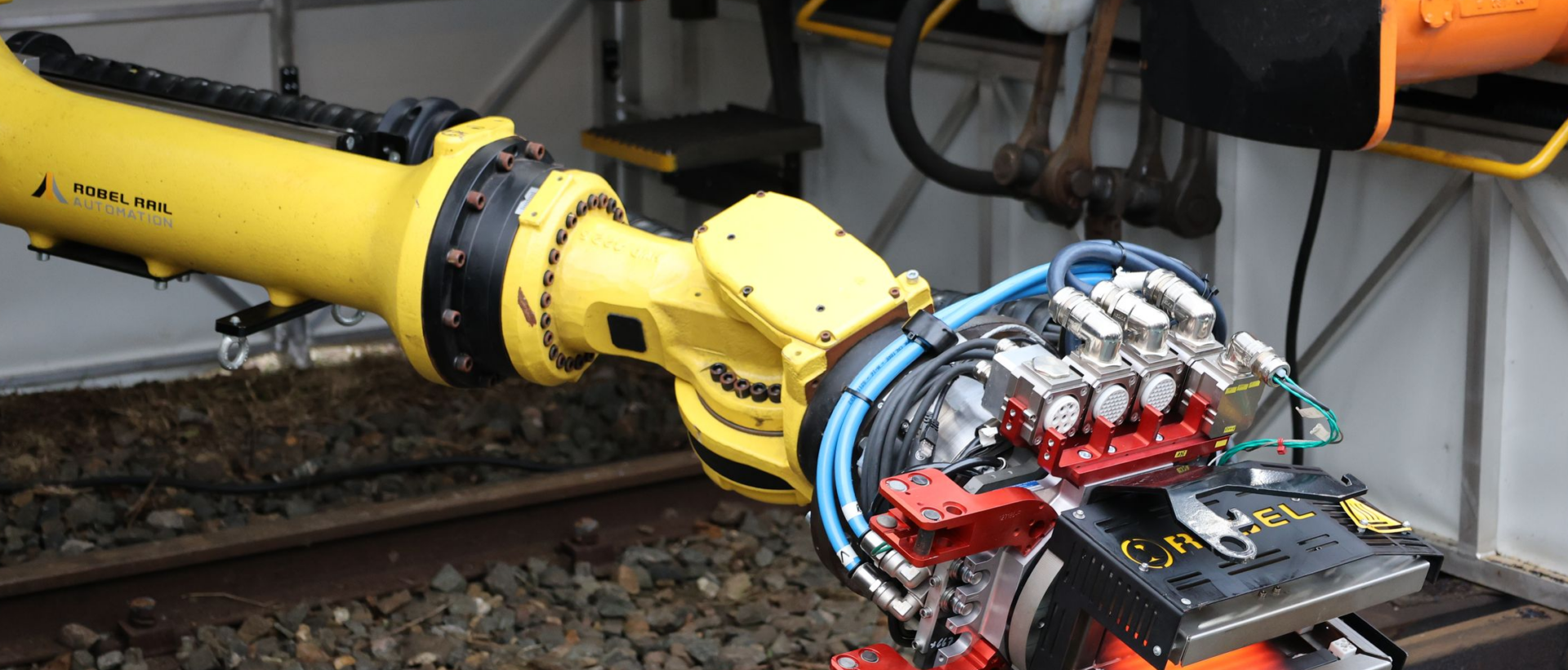

Manual and Automated Defect Detection

The RSCM is easy to set up and to be operated. Only one person is necessary to handle the device. After few steps, the device is ready on track and the rail can be checked for rail defects. All reports are generated automatically during the detection and are saved on a USB device when the operator finishes the measurement. Currently the detection of defects takes place manually with a walking stick (–> picture 2 RSCM device). There will also be a built-in solution in the future for rail-bound maintenance machines or for automated measurement cars.

In summary, RSCM technology is ideal to identify near surface rail flaws at an early stage. So it is possible to derive needed rail treatment actions in time and extend the life cycle of the rail. The technology has been extensively tested and verified by German Railway (DB) and is part of DB’s regulations. But also other international railways like London Underground, metros or rail treatment companies are using RSCM and benefit from it’s easy handling.

This article was originally published by ROBEL.