Over the past 20 years the Robel ROMITAMP (formerly called the GWS 75) has proved to be an extremely effective and reliable machine in tackling localised track quality issues. The machine’s light weight and compact design allows for easy transport and delivery from a low loader, making it ideal for the rapid deployment and repair of emergency track geometry faults as, for example, reported by the high speed track recording coach. Combine this reliability with flexible tamping capability and low whole life costs and you soon realise that this system remains an attractive tamping solution. This proved to be the case, when Network Rail recently decided to invest in two new ROMITAMP tamping machines which are scheduled for delivery in autumn this year.

A Modern Tamping Machine for Difficult Track Access

These latest machines will be fully compliant to RIS 1530 PLT issue 6, gauge compliant to W6a and incorporate the latest tier V engine emission standards as well as bio-degradable oils and lubricators. In additional to standard requirements, the machine is authorised to operate under live OHL and can be on/off tracked on a cant up to 150mm. During the project, the Robel design team have worked closely with experienced fitters and operators to refine and further improve the machine’s maintainability, user ergonomics and reliability. The operator is seated in a safe, comfortable cab that is fully sound proofed and insulated against adverse weather. The seating position allows direct viewing of the tamping operation.

The machine is not just a tamper, but also can be used as a transport unit: There is capacity to carry an additional passenger and a coupling bar is also included to attach equipment trolleys. The intention is that these tamping machines will be primarily used on the jointed single track on the West Highland line and far Northern line in the remote Highlands of Scotland. These are areas where track access is extremely difficult. The ability to easily access & egress, transit to site and transport all that you need for the job are real advantages.

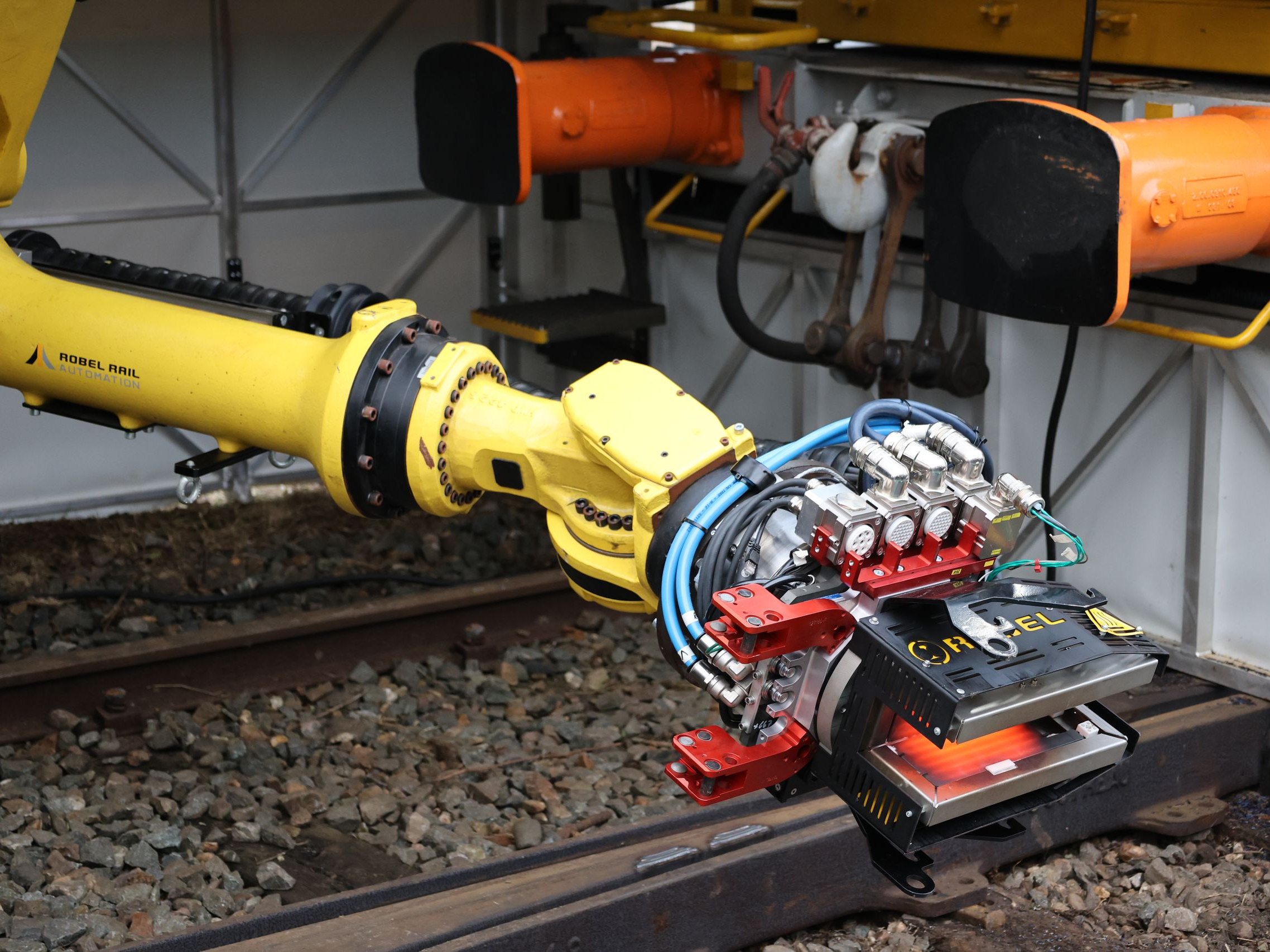

The single transverse tamping head with retracted tines is the ideal flexible design for treating short section on plain line as well as the S&C in the passing loops in station areas. The machine is also ideal for tackling short transition lengths at the run on & off at non-ballasted bridge structures, level crossings and tunnel sections.

With a top transit speed in both directions of 20 km/hr, rapid set up/dismantle times and an integrated turntable, the tamper can be used where track access is difficult and where short work sites are widely dispersed along the route. When set up the tamper can operate at between 80-100 meters per hour.

Better Tamping Results

The tamping head used on these machines features the tried and tested Plasser asynchronous pressure vibration system. The tamping head can be precisely positioned across the track and features a laser sighting system to help the operator and reduce the risk of sleeper strike. Each of the four tamping tines can be individually slewed to the vertical to permit full tamping flexibility. The depth and duration of tamping, under dynamic loading, can be user operated allowing a high degree of control on ballast compaction. A constant pressure oil reservoir guarantees an even and smooth movement during all transport and tamping operations. For this project, the customer decided not to go for a machine with an integrated lifting & slewing function. However, the option remains open to integrate a ROALIGN machine which permits a simple, low cost and flexible automatic track lift and slewing capability to compliment the tamping machine.

Robel are confident their new ROMITAMPs will be as successful as previous machines and continue delivering safety critical repair works in the UK.