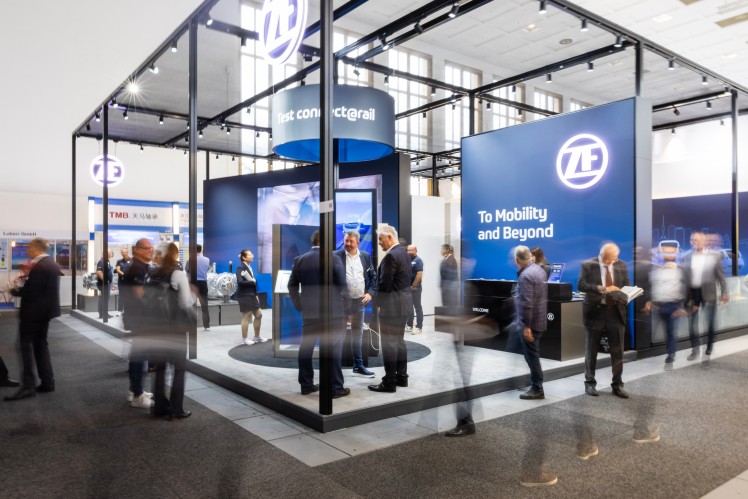

For the technology group ZF and its aftermarket division ZF Aftermarket, the rail vehicle industry is a market of growing importance.

This is demonstrated by the world premiere of a new, modular suspension damper program. For the first time, ZF is enabling passenger railway operators to replace original vibration dampers from other suppliers with ZF components. This retrofit standardizes the dampers used in fleets, reduces operating costs and extends the service intervals of the trains.

ZF, one of the world’s leading suppliers of railway dampers, is applying its development and production expertise to a new market segment: retrofit of rail vehicles with ZF suspension dampers. This is a market with very special challenges: Safety regulations in the railway industry demand that the replacement part corresponds exactly to the properties of the original and must be approved for fitment by the operator.

Covering 95 Percent of Passenger Rail Applications

ZF Aftermarket is meeting this challenge with a new modular damper program that covers 95 percent of passenger rail applications. The market launch will take place in June 2025, initially within Europe.

The suspension dampers are usually replaced as part of the overhaul of the bogie after a mileage of 1.0 to 1.5 million kilometers, which is typically achieved after a service life of six to ten years. As manufacturers of rail vehicles often use dampers from different suppliers in a production batch (dual sourcing or multiple sourcing), it is reasonable for operators to standardize the dampers used when replacing them. This simplifies the procurement process and logistics. Choosing ZF dampers also has the following advantages:

- Lower operating costs: The dampers are designed to minimize stress on wheels, axles and track infrastructure, thereby reducing maintenance costs in the long term.

- Improved supply chain resilience: ZF’s global presence, efficient production network and large number of regional customer service locations guarantee reliable delivery capability and support available at all times, reducing dependence on the original damper manufacturer.

- High product quality: ZF products meet the highest quality criteria. As a result, they guarantee a high level of comfort for rail customers and an extended vehicle service life.

How to Retrofit Rail Vehicles With ZF Suspension Dampers, a Step-By-Step Guide:

- The customer provides ZF Aftermarket with the necessary specifications of the existing damper – either a drawing or the neutral damper specification from the vehicle OEM.

- Using this as a basis, ZF engineering designs the required damper with the same performance based on the modular damper kit.

- The dampers are then produced using batch manufacturing at ZF’s own plans and delivered locally in the desired quantity.

Our new retrofit program is a milestone. With ZF's global engineering expertise and local sales network, we are reducing our customer’s dependence on other suppliers. Rail operators benefit from reliable deliveries and a unique support structure.Marco Neubold, Global Head of Business Line Industrial at ZF Aftermarket said:

This article was originally published by ZF Group.