The essential decision-making process before vehicle enhancement through refurbishment and upgrade

In a world where trains must function on time, every time, pressure is on railway operators to ensure regular upgrades and repairs of their infrastructure, all driven by the needs and expectations of the customer.

When it comes to the components and control systems of rail carriages, the pneumatic door controls and locking systems are often some of the most complex and costly items to refurbish. Safety, long-term reliability and cost-effectiveness are three elements of paramount concern when planning such an undertaking.

There are a number of issues that need careful consideration when investigating and planning such a refurbishment, however, to ensure the best cost solution is achieved both for commercial and technical purposes.

Baselining

Baselining has proven to be a tool always recommended as the first stage of a refurbishment project. Establishing the accurate current operating condition of the equipment ensures an understanding of the true operating environment and can also give an indication of other areas of the complete system and how they impact upon the equipment under consideration.

An assessment of the contamination levels present within the existing pneumatic components and system manifold can help identify issues down the line with filtration and dryers, which if not also addressed will immediately negatively impact on any refurbished equipment.

Baselining is therefore a critical part of the process in ensuring that the true state is identified and all relevant issues are addressed in the planning stage of refurbishment activity.

Required Outcomes

While it may seem a bit of a leap to move directly to defining the desired outcomes straight after the baselining exercise, it is worth remembering that it is after all vital to identify the destination of any journey before commencing travel!

Having clearly defined objectives and agreed key deliverables will enable a full definition of the project’s key requirements and hence the activities required to satisfy and deliver the required outcomes.

Key deliverables such as warranty, life and reliability of the delivered refurbishment activity will all need clear definition and agreement. The impact of these issues on the actual scope of work undertaken is key to the decision-making processes in deciding not only what is undertaken, but also how it is undertaken and what the impact is on the project costs, and hence defining best value both technically and commercially.

Value Assessment

The two activities of baselining and outcome definition will hopefully have provided a clear picture of the scope of works involved, but further work on analysing costs to establish the best methods to achieve both technical and cost requirements will define the final proposition.

The two activities of baselining and outcome definition will hopefully have provided a clear picture of the scope of works involved, but further work on analysing costs to establish the best methods to achieve both technical and cost requirements will define the final proposition.

In refurbishment projects involving a pneumatic system, the costs of manpower for the predominantly labour-intensive processes involved with any potential rebuild of a system retaining the original manifold must be weighed up against the relative cost of supplying a completely new manifold with the benefits of all new warranted parts.

The cost differential between these two options is frequently minimal, especially in projects with a significant quantity of units requiring refurbishment, so when the total cost of the project is considered, including the benefits of ‘soft’ elements such as maintenance and warranty, it often works out to be more economical to replace the entire system with a newly manufactured unit.

Expertise in Refurbishment Solutions

Parker Hannifin has been actively supplying the rail market for many years with a range of components and control systems for use across a wide range of applications where reliable motion and control technology are required. Some of the technologies used include pneumatics, hydraulics and filtration and also products such as hoses and connectors.

It is with this extensive background of supply and application experience that an expertise in refurbishment and enhancement in these technology areas has developed to support on-going rail vehicle operation and life extension projects.

In addition to supplying components to support other partners involved in refurbishment projects, we have also refurbished existing manifold systems, re-used manifolds to rebuild systems and provided newly manufactured complete systems, depending on the particular requirements of the specific project and considering the points raised above.

Introducing New Technologies

When analysing any refurbishment, vehicle modification or upgrade project we are also continually on the lookout to ensure the latest developments in technology are applied when suitable to do so.

This could be as simple as a material change to a seal or diaphragm or as wide-ranging as reviewing the system performance and proposing new solutions. Whichever the case may be, our engineering teams are there to fully engage with and support our customers through the process with all of the expected supporting documentation to mitigate risk.

When considering vehicle improvement projects as opposed to refurbishment, we are also actively engaging in the application of new technologies into the rail market with a range of electromechanical and hybrid technologies.

There is the potential to investigate the application of new technologies to many areas of motion and control on rail vehicles and our focus is to work in partnership with our customers to ensure we are engineering your success.

Could you benefit from working with Parker’s dedicated transportation team; ready to respond to your performance, application, cost, weight and space challenges? Contact us to discuss your solution needs on [email protected]

Application Example – Networker Vehicle Door Control System

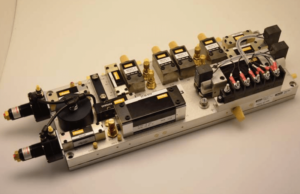

Parker supplied the door control system as part of the fleet refurbishment programme on networker vehicles. In this particular example, Parker supplied new control systems as the technical and financial case supported this approach versus taking the refurbishment route.

There were two main components that were updated during the engineering review process, where full engineering change support documentation packages were supplied to support the work. The first was a material change to the diaphragm in the door obstacle detection valves. This new material used offered an improvement to the life characteristics of the valve. Full documentation to support the reasons for the change, the benefits and an assessment to ensure there was no risk associated with the change was supplied.

The second change was to a valve end cap on the interface to the piloting solenoid valve; this change came as a result of the baselining activities carried out where the potential for damage to the solenoid during handling and maintenance had been identified. Once installed and in use, there was not a functional issue, so there was no requirement to change the product function, just to ensure the interface could not be affected by mishandling or inadvertent contact. A design review was carried out and the end cap design was modified providing flanges either side of the pilot solenoid ensuring protection. Again, this was fully supported by comprehensive documentation.

FOR ALL THE LATEST INFORMATION, NEWS, IMAGES, VIDEOS AND DOCUMENTS FROM PARKER, PLEASE CLICK HERE.