Using Data to Create A Better Future for Rail

By Reece Donovan, CEO, Nomad Digital

One aim of the intelligent train concept is to provide a single maintainer-friendly view of the train. True digital enablement involves the ability to predict failures, highlight hidden problems and issue real-time alerts when failures happen. By using information in a more structured, controlled and repeatable way to plan corrective maintenance, engineers can move towards a condition-based maintenance regime, helping to maximise equipment life, increase availability, reliability and reduce costs. The key is to identify potential failure warning signs before a failure occurs, as the repair cost is usually typically far lower to handle pro-actively as opposed to after the failure has occurred.

Train systems generate a huge amount of data – a standard EMU generates in excess of 5,000 signals, equivalent to 2GB of data per train per day, and gathering this data is costly – data transmission could cost thousands of Pounds per train per year. We think that about 0.25% of this data is critical from a maintenance perspective, so the secret is smart use of the full data set. This requires the ability to access this data, process it and then have an on-shore back office solution which can visualise and analyse it, develop predictive algorithms and integrate procedures into maintenance management. Data can then be compared to understand how fleets are performing relative to each other and, if presented in a standardised form, allow for direct comparisons across manufacturers. A key part of the savings comes from changes in maintenance practices based on the information being generated from the condition-based maintenance solution.

An example of the success of the intelligent train concept is its application to the Portuguese Railway’s Pendolino fleet. Here, 70% of maintenance tasks are now condition-based – in a more controlled and managed environment. This has helped reduce in-service failures by 43%, increase availability by 20%, raise average fleet mileage by one-third and reduce instances of ‘no fault found’ by 40%. Over a 12-year period, maintenance costs have fallen by 57%, demonstrating the significant room for improvement that the intelligent train concept offers.

We think Condition Based Maintenance is hugely powerful. But it is only through the insight and intelligence of the engineers and maintainers that use it, that it becomes most effective.

As part of our ‘connecting everything’ vision, and with the advent of IoT, Big Data and Artificial Intelligence, Conditioned Based Maintenance is becoming an integral part of realising the intelligent train. Nomad Tech, our joint venture with EMEF and the Portuguese Railways is focused on this market.

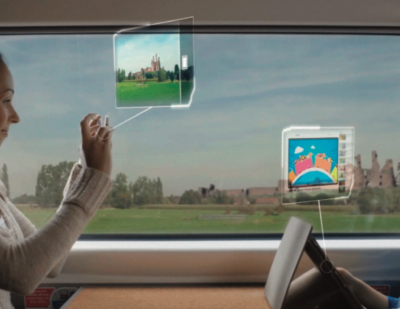

Our Solutions allow you to sense, collect and deliver data about the train to the shore and this can be used for a number of purposes such as Condition Based Maintenance (CBM), driver advisory systems, to identify energy efficiencies and in support of power electronics. We also provide consultancy on maintenance practices and how these can be improved to save money.

We’ve recently won a large contract, which uses this data to improve the operational and reliability nature of the trains. This is being used with a transport authority to ensure that the franchise is delivering the on the service levels and value that they have promised.

If you would like to here more about our CBM please visit the Nomad team at Rolling Stock Maintenance 2018 in London, or get in touch with [email protected]