Metal Contacts Manufacturer to Lend Rail Subcontractors a Helping Hand

Precious metal contacts and precision metal pressings specialist Samuel Taylor Limited (STL) is currently reviving its traditional links with the rail industry utilising many unique tools and accumulated know-how dating back from the 1960s and 70s, in a move focused on saving rail subcontractors thousands on refurbishment projects.

Having just joined the Rail Alliance and already working on a rising number of projects within the sector, some of the companys expertise and tooling retrieved from the companys tool storage racks is set to save a significant amount of time and money for rail subcontractors tasked with refurbishing power switches and associated metal contacts and components within trains.

New Investment in Tool Design Software

Typical projects often involve a relatively small quantity of components. Producing the tooling for these components in such a small volume is likely to be costly. In the past there were many more options in the supply chain, but over the years UK based supply has dwindled and often moved overseas. STL has maintained its prototype and small order manufacturing capability within the UK, while expanding its core volume precision stamping market with the addition of several new heavier presses, 100T, 110T and 300T load. Recent investment at STL in state of the art tool design software and toolroom EDM machines can also be focussed on rail refurbishment or new design projects.

Electrical contact materials include silver alloy, bi-metal and tri-metal rivets as well as inlay strips and profiled wires. STL manufactures these products at its UK plant, exporting over 80% globally. Bi-metal contact rivets save a lot of cost over solid silver alloy rivets and are manufactured in millions using the companys proprietary cold heading processes, the bond consolidated by a specialised heat treatment facility in-house. Working with customers design engineers, STL is able to minimise cost by focusing on applying contact materials only where needed and subsequently building the complete sub-assembly.

For heavy current switching in contactors, bi-metal rivets are usually a good option, whilst STLs profile wire or bi-metal strip products can give even higher cost saving options for small load carrying components. According to STLs Sales Manager Carl Siviter, the company has a range of product solutions to suit most applications.

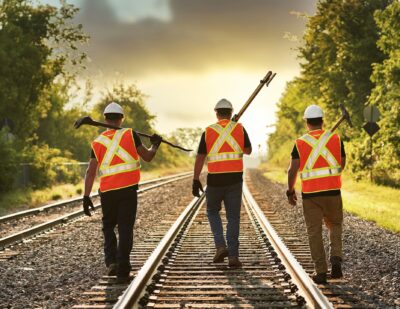

Exhibiting at this years Railtex show in London, the company is particularly aiming to forge new connections with rail subcontractors who need access to STLs knowledge and capability in electrical contact materials. With their precious contact materials potentially fitting a wide range of switches that can be found in electrical train engines as well as the carriages, the firms tools and expertise are likely to help rail engineers to carry out rail refurbishments in the most efficient and cost effective way.

STLs Managing Director Alastair Gordon comments, holding on to our small order capability has been a good decision in the face of trends over recent years towards more high volume manufacture and automation. Of course, we are also able provide that kind of volume, with high speed pressing capability available where required, but the small order capability is perfect for serving niche or smaller markets.

The companys commitment to the rail sector has also been manifested by STLs recent decision to join the Rail Alliance. Aiming to provide businesses with the opportunities to network, collaborate and innovate with suppliers and customers alike, the B2B organisations membership base spans all aspects of the railway and supporting industries and unites representatives from the public and private sector.